-

151

-

'14 • KX-SM-204

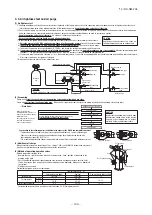

Outdoor unit(Master)

SW4-7 OFF

Outdoor unit No.20

Indoor unit

Outdoor unit No.20

Indoor unit No.01

Indoor unit

Outdoor unit No.20

Indoor unit No.02

Indoor unit

Outdoor unit No.20

Indoor unit No.03

Indoor unit

Outdoor unit No.22

Indoor unit No.04

Indoor unit

Outdoor unit No.22

Indoor unit No.05

Indoor unit

Outdoor unit No.22

Indoor unit No.06

Outdoor unit(Master)

SW4-7 OFF

Outdoor unit No.22

Outdoor unit(Slave)

SW4-7 ON

Outdoor unit No.20(21)

Outdoor unit(Slave)

SW4-7 ON

Outdoor unit No.22(23)

Note:

Slave unit address is master unit +1. Address of second slave unit is master

unit +2. When setting the address for master unit, take care to avoid

duplication with other systems. Otherwise, it cannot operate. (Error: E-31)

(2) When the remote control wire runs parallel to another power source wire or when it is subject to outside noise, such as from a high-frequency device, use

shielded wire. (Be sure to ground only one end of the shielded wire.)

●

Address setting methods

The following address setting methods can be used. The procedure for automatic address setting is different from the conventional one.

Please use the automatic address setting function after reading this manual carefully.

This control system controls the controllers of more than one air conditioner's outdoor unit, indoor unit and remote control unit through communication control, using the microcomputers built in

the respective controllers. Address setting needs to be done for both outdoor and indoor units. Turn on power in the order of the outdoor units and then the indoor units.

Use 1 minute as the rule of thumb for an interval between them.

The communication protocol can be chosen from following two types. One of them is the conventional communication protocol (previous SL) and the other is the new communication protocol (new

SL). These two communication protocols have their own features and restrictions as shown by Table 6-3. Select them according the indoor units and the centralized control to be connected.

When signal cables are connected into a network involving outdoor units, indoor units or centralized control equipment that do not support new SL, please select communications in the previous SL

mode, even if the refrigerant system is separated from theirs.

When communication is established after setting addresses, check the communication protocol with the 7 segment display panel of the outdoor unit.

CASE 1

CASE 2

※

1 Do not connect the signal line between outdoor units on the different refrigerant lines to A1 and B1. Do not connect the signal line between outdoor units on the same

refrigerant line to A2 and B2. This may interrupt proper address setting. (Case 3)

Do not connect the signal line between indoor unit and outdoor unit to A2 and B2. This may interrupt proper address setting. (Case 4)

※

2 In Case 2, automatic address setting is not available. Set addresses manually.

7-1. Unit address setting

Communication protocol

Address setting method

OK

※

1

×

※

2

OK

OK

OK

OK

OK

OK

OK

×

×

OK

new SL

previous SL

Automatic Manual Automatic Manual

7. CONTROL SETTINGS

Case 1

Case 2

When signal lines linking plural refrigerant systems are provided between outdoor units.

(When the network connector is disconnected, refrigerant systems are separated each other)

When signal lines linking plural refrigerant systems are provided between indoor units.

When only one refrigerant system is involved (signal lines do not link plural refrigerant systems)

When plural refrigerant systems

are linked with signal lines

(e.g., to implement centralized

control)

Network connector

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Indoor unit

Indoor unit

Indoor unit

Indoor unit

A

B

A

B

A

B

A

B

Refrigerant pipe

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Indoor unit

Indoor unit

Indoor unit

Indoor unit

A

B

A

B

A

B

A

B

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

Signal line

(1)

A standard remote control wire is 0.3mm

2

x 2 cores (FD

○△△

KXE6 indoor unit), 0.3mm

2

x 3 cores (FD

○

A

△△

KXE4.5 indoor unit).

It can be

extended

up to 600m. For a remote control wire exceeding 100m,

please upgrade wire size

as specified in the table below

.

Remote control wiring specifications

100 to 200

To 300

To 400

To 600

0.5mm

2

×

2 cores

0.75mm

2

×

2 cores

1.25mm

2

×

2 cores

2

mm

2

×

2 cores

Length (m)

Wire size

FD

○△△

KXE6 indoor unit

(3) The signal lines can also be connected using the method shown below.

Outdoor unit

Outdoor unit

Indoor unit

Indoor unit

Indoor unit

Outdoor unit

Indoor unit

Indoor unit

Outdoor unit

Indoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

○

Loop wiring prohibited.

The signal lines cannot form a

loop, so the wirings shown as .......

in the diagram are prohibited.

Important

6-3. Method of connecting signaling wires

The communication protocol can be choosen from following two types. One of them is the conventional Superlink (hereinafter previous SL) and the other is the new Superlink

Ⅱ

(hereinafter new SL) . These two communication protocols have the following advantages and restrictions, so please choose a desirable one meeting your installation conditions

such as connected indoor units and centralized controller. When signal cables are connected into a network involving outdoor units, indoor units or centralized control equipment

that do not support new SL, please select communications in the previous SL mode, even if the refrigerant system is separated from theirs.

(1) When one outdoor unit is used.

○

Indoor and outdoor signal lines do not have a polarity.

Any of the connections in the following illustration can be made.

(2) When plural outdoor units are used

Signal line

Refrigerant pipe

Network connector

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Indoor unit

Indoor unit

Outdoor signal line

terminal block

Indoor signal line

terminal block

A

1 B1

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

A1

B1

A1

B1

A B

A B

A B

A

B

A

B

A

B

A

B

Indoor unit

Indoor unit

A

B

A

B

●

Signal cables are for DC 5 V. Never connect wires for 220/240 V or 380/415 V.

Protective fuse on the PCB will trip.

①

Confirm that signal cables are prevented from applying 220/240 V or 380/415 V.

②

Before turning the power on, check the resistance on the signal cable terminal block. If it is less than 100Ω, power supply cables may be connected to the signal cable terminal block.

When units of FD

○△△

KXE6 Series, FD

○△△

KXZE1 series are connected:

Standard resistance value=5,100/Number of connected units.

When units of FD

○

A

△△

KXE4 and 5 Series only are connected:

Standard resistance value=9,200/Number of connected units.

When units of FD

○△△

KXE6 Series, FD

○△△

KXZE1 series and units of FD

○

A

△△

KXE4 and 5 Series are connected in a mixture:

Standard resistance value=46,000/[(Number of connected FD

○

A

△△

KXE4 and 5 Series units x 5) + (Number of connected FD

○△△

KXE6 and KXZ Series

units x 9)]

The number of connected units includes those of indoor units, outdoor units and SL devices..

If the resistance value is less than 100Ω, disconnect the signal cables temporarily to divide to more than one network, to reduce the number of indoor units on the same

network, and check each network.

Outdoor unit setting (SW5-5)

No. of connectable indoor units

No. of connectable outdoor units in a network

Signal cable (total length)

Signal cable (furthest length)

Connectable units to a network

ON

Max. 48

Max. 48

Up to 1000m

Up to 1000m

Units not supporting new SL (FD

○

A

△△

KXE4.5

series)

Units supporting new SL (FD

○△△

KXE6

series, FD

○△△

KXZ

series)

Can be used together.

OFF (Factory default)

Max. 128

Max. 32

Up to 1,500 m for 0.75 mm

2

shielding wire (MVVS)

Up to 1,000 m for 1.25 mm

2

shielding wire (MVVS)

Up to 1000m

Units supporting new SL (FD

○△△

KXE6

series, FD

○△△

KXZ

series)

Conventional communication protocol (previous SL)

Communication protocol

New communication protocol (new SL)

Note: For FDT224 and 280 models, calculate the number of units taking 1 indoor unit as 2 units for the sake of communication.

Indoor and outdoor units signal cables

●

Connect the signal cable between indoor and outdoor units and the signal cable between outdoor units belonging to the same refrigerant line to A1 and B1.

●

Connect the signal line between outdoor units on different refrigerant lines to A2 and B2.

●

Please use a shielded cable for a signal line and connect a shielding earth at all the indoor units and outdoor units.

CASE 3

CASE 4

Indoor unit address setting

000

-

127[47]

000

000

00

-

31[47]

49

49

Indoor unit address setting

00

-

47

49

×

00

-

47

49

×

00

-

31[47]

49

00

〜

31

Outdoor unit address setting

00

-

47

49

×

Outdoor unit address setting

0 1

2

3

4

5

6

7

8

9

0 1

2

3

4

5

6

7

8

9

●

Address No. setting

Set SW1 through 4 and SW5-2 provided on the PCB and SW1 & 2 provided on the outdoor unit PCB as shown in the drawings below.

●

Summary of address setting methods (figures in [ ] should be used with previous SL)

Do not set numbers other than those shown in the table, or an error may be generated.

Note: When units supporting new SL are added to a network using previous SL such as one involving FD

○

A

△△

KXE4.5 series units, choose previous SL for the communication protocol and set addresses

manually.

Since the models FDT224 and 280 have 2 PCBs per unit, set different indoor unit No. and SW on each PCB.

●

An outdoor unit No., which is used to identify which outdoor unit and indoor units are connected in a refrigerant system, is set on outdoor unit PCB and indoor unit PCB. Give the same outdoor unit

No. to all outdoor unit and indoor units connected in same refrigerant system.

●

An indoor unit No. is used to identify individual indoor units. Assign a unique number that is not assigned to any other indoor units on the network.

①

Address setting of outdoor unit Before turning on the power, set as follows. The outdoor address is registered when the power is turned on.

Set

the outdoor No. switches

in a range of

00 – 31 [or 00 - 47 for old SL].

Take care not to duplicate with other outdoor unit No. on the network.

In the same way also on the master unit of combination,

set the rotary switch for outdoor No.

in a range of 00 - 31 [or 00 – 47 for old SL]

For slave units of combination,

set the rotary switches for outdoor No. at

the same outdoor No. as the master unit of combination.

When 2 units are combined, set the dip switch SW4-7 of slave unit to ON. When 3 units are combined, set the dip switch SW4-7 of slave unit 1 to ON

and the dip switch SW4-8 of slave unit 2 to ON.

(Use same setting for outdoor No. of master unit and slave unit.)

②

Address setting of indoor unit

Before turning on the power, set as follows. Indoor address is registered when the power is turned on.

Set

the indoor No. switch

in a range of

000 – 127 [or 00 – 47 for old SL].

For

the outdoor No switches,

set corresponding outdoor No. in a range of

00 – 31 [or 00 – 47 for old SL)].

Set with care not to duplicate with other indoor No. on the network.

Above list is an example.

The address on the network is master unit

+1 for the slave unit.

If the slave unit address is larger than 31 [or 47 for old SL], the

address is assigned sequentially starting from 00.

When setting sequential addresses, take care not to duplicate the

master unit address in the refrigerant system B with addresses of

slave units in the refrigerant system A.

③

Turn on power in order from the outdoor unit to indoor units. Give a one-minute or longer interval for them.

* When there are some units not supporting new SL connected in the network, set SW5-5 to ON to choose the previous SL communication mode.

In the case of previous SL, the maximum number of indoor units connectable in a network is 48.

Incorrect cable connection

(Cables between outdoor units on different refrigerant lines are connected to A1/B1.)

Incorrect cable connection

(Cables between indoor and outdoor units are connected to A2/B2.)

Incorrect cable connection

(Cables between outdoor units on the same refrigerant line are connected to A2/B2.)

Manual address setting

(previous SL/new SL)

Units supporting new SL

Units NOT supporting new SL

SW1 (SW3)

SW2 (SW4)

For ten’s place

For one’s place

By inserting a flat driver

(precision screw driver) into this

groove and turn the arrow to

point a desired number.

Indoor PCB

Outdoor PCB

SW1, 2 (blue)

SW3, 4 (green)

SW5-2

SW1, 2 (green)

For setting indoor No. (The ten’s and one’s)

For setting outdoor No. (The ten’s and one’s)

Indoor No. switch (The hundred’s Place) [OFF : 0, ON : 1]

For setting outdoor No. (The ten’s and one’s)

Automatic address setting for

multiple refrigerant systems installation

(with new SL only)

Automatic address setting for

single refrigerant system installation

(previous SL/new SL)

Indoor No. switch

Outdoor No. switch

Outdoor No. switch

Indoor No. switch

Outdoor No. switch

Outdoor No. switch

Unless stated otherwise, the following procedures apply, when new SL is chosen for the communication protocol.

When previous SL is chosen, use figures shown in [ ] in carrying out these procedures.

Manual address setting Generally applicable to new SL/previous SL, use figures in [ ] with previous SL.

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Indoor unit

Indoor unit

Indoor unit

Indoor unit

A

B

A

B

A

B

A

B

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Indoor unit

Indoor unit

Indoor unit

Indoor unit

A

B

A

B

A

B

A

B

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

A1・B1 A2・B2

Outdoor unit

Master

Slave

Master

Slave

Master

Slave

SW1

2

2

2

2

3

3

SW2

2

2

4

4

1

1

SW4-7

OFF

ON

OFF

ON

OFF

ON

Address on network

22

23

24

25

31

00

Refrigerant system

A

B

C

Outdoor unit

Master

Slave 1

Slave 2

Master

Slave 1

Slave 2

Master

Slave 1

Slave 2

SW1

2

2

2

2

2

2

3

3

3

SW2

2

2

2

5

5

5

1

1

1

SW4-7

OFF

ON

OFF

OFF

ON

OFF

OFF

ON

OFF

SW4-8

OFF

OFF

ON

OFF

OFF

ON

OFF

OFF

ON

Address on network

22

23

24

25

26

27

31

00

01

Refrigerant system

A

B

C

Slave setting

The same setting with the master unit’s address number

(In the network, “the setting

+

1” is assigned.)

indicates signaling wires (A/B).

indicates refrigerant piping.

Example of address setting (manual)

Take care not to assign an address duplicating with

one used in another system.

(Use every second number in setting an address)

Set an outdoor unit number in the system

Take care not to assign a duplicating address in a network.

Automatic address setting Generally applicable to new SL/previous SL, use figures in [ ] with previous SL.

With new SL, you can set indoor unit addresses automatically even for an installation involving multiple refrigerant systems connected with same network, in addition to the conventional automatic

address setting of a single refrigerant system installation.

However, an installation must satisfy some additional requirements such as for wiring methods, so please read this manual carefully before you carry out automatic address setting.

②

Indoor unit address setting

Set as follows before you turn on power.

Make sure that the

Indoor Unit No. switch

is set to

000 [in the case of previous SL: 49] (factory setting).

Make sure that the

Outdoor Unit No. switch

is set to

49 (factory setting).

③

Turn on power in order from the outdoor unit to indoor units. Give a one-minute or longer interval for them. Unlike the procedure set out in (2) below, you need not change settings from the 7

segment display panel.

④

Make sure that the number of indoor units indicated on the 7 segment display panel agrees with the number of the indoor units that are actually connected to the refrigerant system.

(This option is available when the interconnection wiring among refrigerant systems is on the outdoor side and new SL is chosen as the communication protocol.)

(2) In the case of a multiple refrigerant systems installation

(Applicable to new SL only. In the case of previous SL, set addresses with some other method.)

①

Address setting of outdoor unit Before turning on the power, set as follows.

Set

the outdoor No. switches

in a range of

00 – 31.

Take care not to duplicate with other outdoor unit No. on the network.

In the same way also on the master unit of combination,

set the rotary switch for outdoor No.

in a range of 00 - 31

For slave units of combination,

set the rotary switches for outdoor No. at

the same outdoor No. as the master unit of combination.

When 2 units are combined, set the dip switch SW4-7 of slave unit to ON. When 3 units are combined, set the dip switch SW4-7 of slave unit 1 to

ON and the dip switch SW4-8 of slave unit 2 to ON.

(Use same setting for outdoor No. of master unit and slave unit.)

②

Address setting of indoor unit

Before turning on the power, set as follows.

Make sure that the

Indoor Unit No. switch

is set to

000 (factory setting).

Make sure that the

Outdoor Unit No. switch

is set to

49 (factory setting).

③

Isolate the present refrigerant system from the network.

Disengage the

network connectors (white 2P)

of the outdoor units. (Turning on power without isolating each refrigerant system will result in erroneous address setting.)

[STEP2]

(Power on and automatic address setting)

④

Turn on power to the outdoor unit

Turn on power in order from the outdoor unit to indoor units. Give a one-minute or longer interval for them.

⑤

Select and enter “1” in P31 on the 7 segment display panel of each outdoor unit (master unit in case of combination) to input “Automatic address start.”

⑥

Input a starting address and the number of connected indoor units.

Input a starting address in P32 on the 7 segment display panel of each outdoor unit (master unit in case of combination).

⑦

When a starting address is entered, the display indication will switch back to the “Number of Connected Indoor Units Input” screen.

Input the number of connected indoor units from the 7 segment display panel of each outdoor unit (master unit in case of combination). Please input the number of connected indoor units (on

the same refrigerant line in case of combination) for each outdoor unit. (You can input it from P33 on the 7 segment display panel.)When the number of connected indoor units is entered, the 7

segment display panel indication will switch to “AUX” and start flickering.

[STEP3]

(Automatic address setting completion check)

⑧

Indoor unit address determination

When the indoor unit addresses are all set, the 7 segment display panel indication will switch to “AUE” and start flickering.

If an error is detected in this process, the display will show “A

○○

.”

Check the 7 segment display panel of each outdoor unit (master unit in case of combination).

Depending on the number of connected indoor units, it may take

about 10 minutes

before the indoor unit addresses are all set.

Address setting procedure

(perform these steps for each outdoor unit)

[STEP1]

(Items set before turning on power)

CAUTION

If the slave unit is not

specified, a compressor

failure may result.

①

Address setting of outdoor unit Before turning on the power, set as follows.

Confirm that

the outdoor No. switch

is set

at 49 by the default.

t

In the same way also on the master unit of combination,

confirm that the rotary switch for outdoor No. is set

at 49 by the default.

t

In the same way also on the slave unit of combination,

confirm that the rotary switch for outdoor No. is set

at 49 by the default.

When 2 units are combined, set the dip switch SW4-7 of slave unit to ON. When 3 units are combined, set the dip switch 4-7 of slave unit 1 to ON

and the dip switch SW4-8 of slave unit 2 to ON.

(1) In the case of a single refrigerant system installation

(Generally applicable to new SL/previous SL, use figures in [ ] with previous SL.)

Outdoor unit

Master

Slave

SW1

4

4

SW2

9

9

SW4-7

OFF

ON

Address on network

49

00

Outdoor unit

Master

Slave 1

Slave 2

SW1

4

4

4

SW2

9

9

9

SW4-7

OFF

ON

OFF

Address on network

49

00

01

SW4-8

OFF

OFF

ON

②

OFF

①

OFF

②

indoor000/outdoor 49

(

factory setting

)

①

01,03(Ex

)

③

Disconnect(each outdoor unit)

STEP1

STEP2

STEP3

STEP4

ー

ー

ー

ー

⑨

Connect(each outdoor unit)

ー

ー

⑩

Set in P34 on the 7 segment display

panel of any outdoor unit.

⑪「

End

」

ー

ー

ー

ー

ー

ー

ー

ー

⑧

“AUE”(blink), or “A

○○

” in error events.

Indoor unit power source

Outdoor unit power source

Indoor unit

(indoor/outdoor No.SW)

Outdoor unit (outdoor No.SW)

Network connectors

Start automatic address setting

Set starting address

Set the number of indoor unit

Polarity setting

7 segment display

④

ON

④

ON

⑦

outdoor 01:

「

03

」

(Ex)

outdoor 03:

「

03

」

(Ex)

⑥

outdoor 01:

「

01

」

(Ex)

outdoor 03:

「

04

」

(Ex)

⑤

Select “Automatic Address Start”

on each outdoor unit.

⑦[

AUX

]

(Blink

)

ー

ー

ー

ー

[STEP4]

(Network definition setting)

⑨

Network connection

When you have confirmed an “AUE” indication on the display of each outdoor unit,

engage the network connectors

again.

⑩

Network polarity setting

After you have made sure that the network connectors are engaged

, select and enter “1” in P34 on the 7 segment display panel of

any outdoor unit (on only 1 unit : master unit in

case of combination)

to specify network polarity.

⑪

Network setting completion check

When the network is defined, “End” will appear on the 7 segment display panel. An “End” indication will go off, when some operation is made from the 7 segment display panel or

3 minutes after.

power cable (220-240V)

Indoor unit

Indoor unit

In addition to a possible wiring error between indoor and outdoor units, there are other possibilities of erroneous wiring as illustrated below.

It will result in a blown signal line fuse (CNK).

①

Wrong wiring between signaling wires and

remote control wires.

②

Connecting power cables to the signaling wire

terminal block.

For remote control

Terminal block

For signal wires

Terminal block

For power cables

Terminal block

For signal wires

Terminal block

CAUTION

Remote control wire

Signal wire

Signal wire

X Y

A B

L N

A B