'19 • PAC-SM-309

-

81

-

*

Po

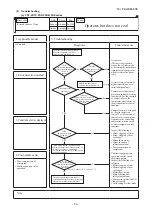

wer source check:

Measure the po

wer source L1,L2,L3

(It is normal if it is

A

C380-415V)

Noise f

ilter check:

There should be continuity

.

There should be no shorts between phases.

DC reactor contiuity

check:55m

Ω

or less

LED2 (Red)

LED1

(Green)

LED2(Red) check:

1~5 time flash

(Refer to page 52

・

53

)

When the outdoor

unit f

an motor is

anomalous.

(Refer to page

122

・

165

)

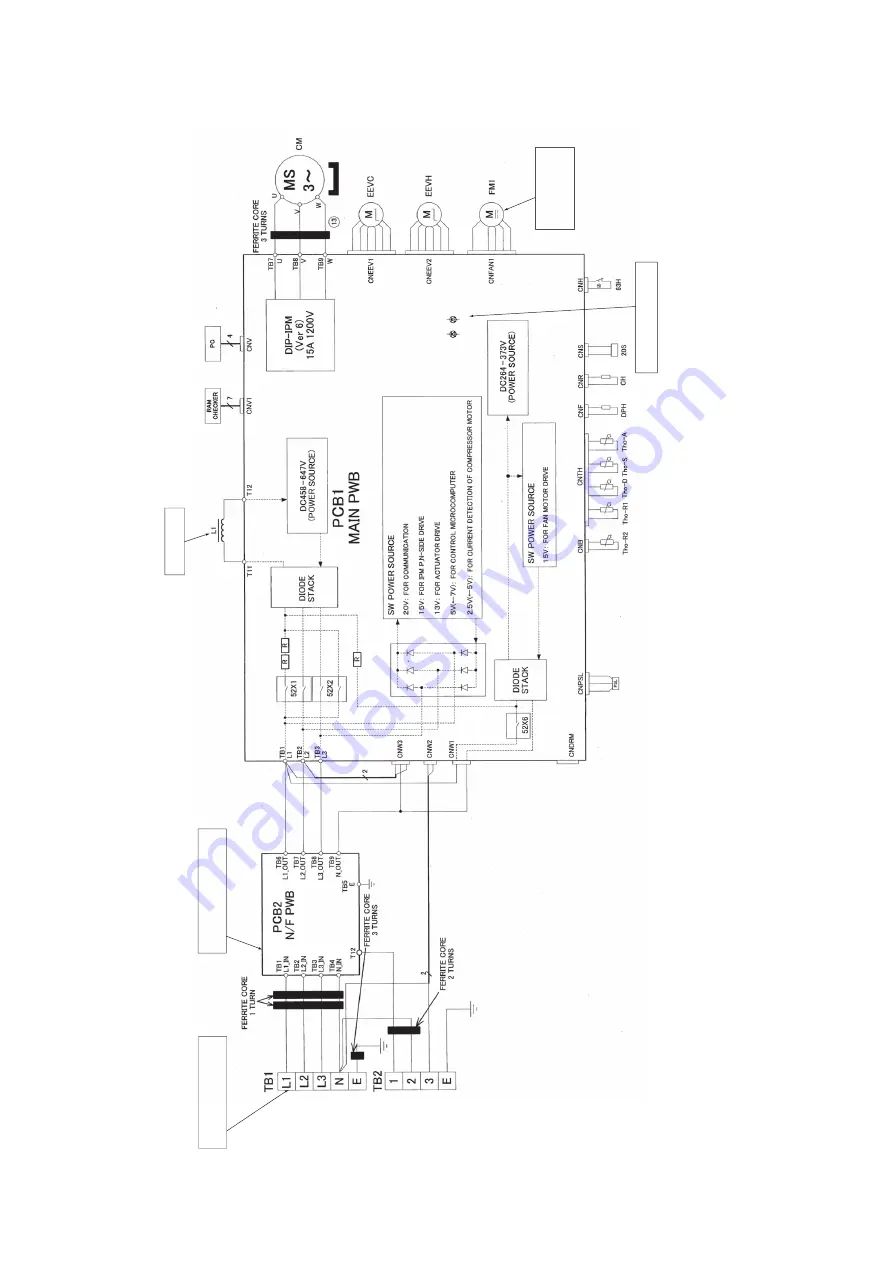

FDC100,125,140VSA-W

●

Outdoor unit check points

Check items with the *mark when the po

wer is ON.

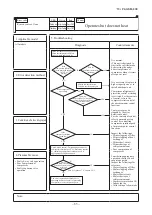

Summary of Contents for FDC100VNA-W

Page 70: ... 19 PAC SM 309 69 LED2 Red LED1 Green ...

Page 72: ... 19 PAC SM 309 71 ...

Page 74: ... 19 PAC SM 309 73 LED2 Red LED1 Green ...

Page 76: ... 19 PAC SM 309 75 ...

Page 183: ... 19 PAC SM 309 182 1 e SRK series PHA012D402 ...

Page 184: ... 19 PAC SM 309 183 Screw ...

Page 185: ... 19 PAC SM 309 184 3 PHA012D402 ...

Page 186: ... 19 PAC SM 309 185 4 PHA012D402 ...