-

181

-

Drainage test

q

Check that water is draining thoroghly during test run, and that there are no water leaks from the joints and the drain pan.

w

The test has to be performed even if the unit is installed in the season when the unit is used for heating.

e

In a new house, perform the test before the ceiling is fitted.

• Using a water pump, pour about 1000 cc of water to the drain pan through

the supply outlet.

• Check the transparent drain-out section of the drain hose for normal flow of

drainage.

* While observing the noise from the drain motor, test drain operation.

• Take off the drain plug to release the water. After the water is drained, place

the drain pulg back where it was..

* Be careful not to get splashed when pulling the drain plug.

Forced drain pump operation

q

In case electrical wiring work finished

Drain pump can be operated by remote controller (wired).

For the operation method, refer to Operation for drain pump in the installation manual for wiring work.

w

In case electrical wiring work not finished

Drain pump will run continuously when the dip switch “W7-1” on the indoor unit PCB is turned ON, the Connector CNB is

disconnected, and then the power supply (230VAC on the terminal block

q

and

w

) is turned ON.

Make sure to turn OFF “W7-1” and reconnect the Connector CNB after the test.

Put the tip of the feed water pump

in the drain pan of the unit body

Drain plug

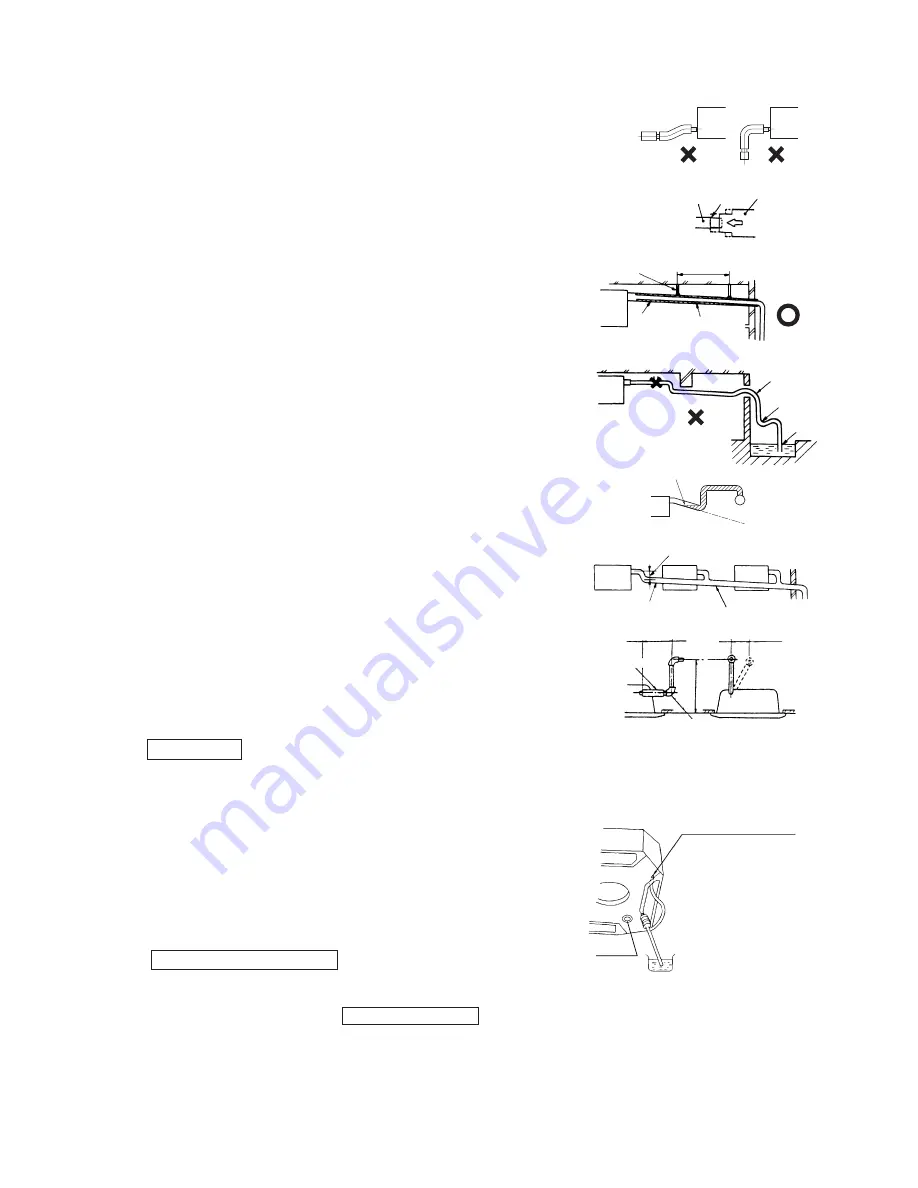

3) Care must be taken so as not to allow an adhesive to run into the drain hose.

When it is hardened, it can cause a breakage of a flexible part, if the flexible

part receives stress.

4) Use VP-20 general-purpose hard PVC pipes for drain piping.

5) Insert the drain hose supplied as an accessory (soft PVC end) to the stepped

part of the unit’s drain socket and then fasten it with the clamp also supplied as

an accessory.

6) Adhesive must not be used.

a) Attach a VP-20 joint (to be procured locally) to joint it with the drain hose

(hard PVC end) and then attach a VP-20 (to be procured locally) to the joint.

b) Give the drain piping a descending grade (1/50-1/100) and never create a

bump to go over or a trap.

c) In connecting drain pipes, care must be taken so as not to apply force to the

unit side piping and fix the pipe at a point as close to the unit as possible.

d) Do not create an air vent under any circumstances.

e) When drain piping is implemented for more than one unit, provide a col-

lecting main about 100 mm below the units’ drain outlets from which it

collects drain. Use a VP-30 or larger pipe for a collecting main.

f) Do not fail to provide heat insulation at the following two points because they

can cause dew condensation and a resultant water leak.

7) Drain socket

After a drain test is completed, apply a pipe cover (small: accessory) onto the

drain socket, cover the pipe cover (small), the clamp and part of the drain hose

with a pipe cover (large: accessory) and wrap it with a tape completely without

leaving any gaps.

(Cut pipe covers into appropriate shapes)

8) Hard PVC pipes laid indoor

a) Since a drain pipe outlet can be raised up to 600 mm from the ceiling, use

elbows, etc. to install drain pipes, if there are obstacles preventing normal

drain pipe arrangement. When the drain pipe is raised at a point far from a

unit, it can cause an overflow due to a back flow of drain upon stoppage, so

arrange piping to keep the dimensions specified in the illustration shown on

the left.

b) Install the drain pipe outlet where no odor is likely to be generated.

c) Do not lead the drain pipe into a ditch where the generation of harmful gas

such as sulfuric gas or flammable gas is expected. A failure to observe this

instruction may cause such harmful or flammable gas to flow into the room.

Drain hose

Stepped

part

Drain socket

1.5 m ~ 2 m

Suspension

bolts

Descending slope

greater than 1/100

Insulation

material

No bump

Air vent

No trap

Not

touching

the water

As wide as possible

(about 100 mm)

VP30

Joint for VP-25

(not included)

Descending slope

greater than 1/100

295 ~ 325 mm

100 mm or less

Drain hose

600 mm or less

Trapped air will

generate noises.

Summary of Contents for FDC112KXEN6

Page 116: ... 112 4 Sensible heat capacity ...

Page 117: ... 113 ...

Page 118: ... 114 ...

Page 119: ... 115 ...

Page 120: ... 116 ...

Page 121: ... 117 ...

Page 122: ... 118 ...

Page 123: ... 119 ...

Page 124: ... 120 ...

Page 125: ... 121 ...

Page 126: ... 122 ...

Page 127: ... 123 ...

Page 128: ... 124 ...

Page 129: ... 125 ...

Page 130: ... 126 ...

Page 131: ... 127 ...

Page 132: ... 128 ...

Page 133: ... 129 ...

Page 134: ... 130 ...

Page 135: ... 131 ...

Page 136: ... 132 ...

Page 137: ... 133 ...

Page 138: ... 134 ...

Page 139: ... 135 ...

Page 140: ... 136 ...

Page 141: ... 137 ...

Page 142: ... 138 ...

Page 143: ... 139 ...

Page 144: ... 140 ...

Page 145: ... 141 ...

Page 146: ... 142 ...

Page 147: ... 143 ...

Page 148: ... 144 ...

Page 149: ... 145 ...

Page 150: ... 146 ...

Page 151: ... 147 ...

Page 152: ... 148 ...

Page 153: ... 149 ...

Page 154: ... 150 ...

Page 155: ... 151 ...

Page 156: ... 152 ...

Page 157: ... 153 ...

Page 158: ... 154 ...

Page 159: ... 155 ...

Page 160: ... 156 ...

Page 161: ... 157 ...

Page 162: ... 158 ...

Page 163: ... 159 ...

Page 164: ... 160 ...

Page 165: ... 161 ...

Page 166: ... 162 ...

Page 167: ... 163 ...

Page 168: ... 164 ...

Page 169: ... 165 ...

Page 170: ... 166 ...

Page 171: ... 167 ...

Page 172: ... 168 ...

Page 173: ... 169 ...