-

15

-

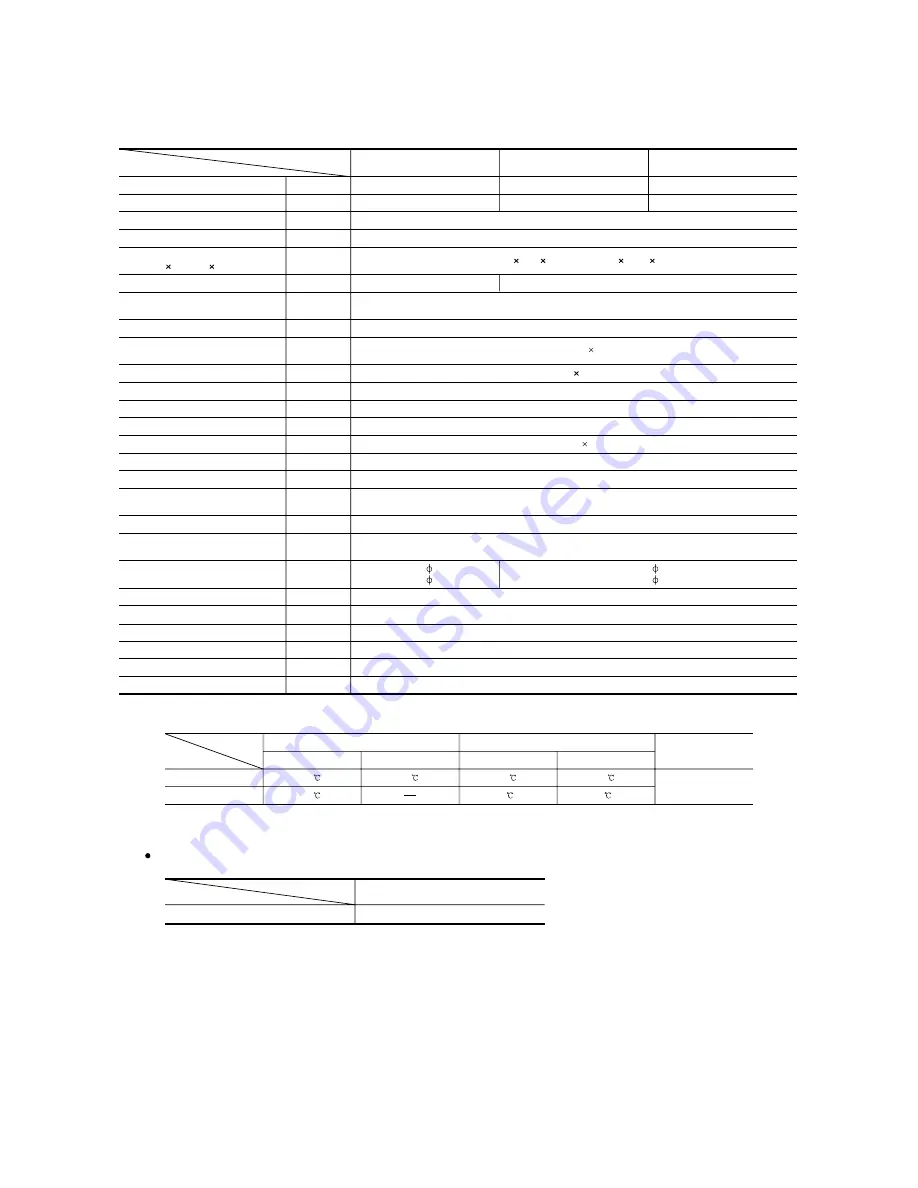

Models FDTW28KXE6, 45KXE6, 56KXE6

Item

kW

kW

W

CMM

kg

Unit:18 Panel:7

Unit:19 Panel:7

30 1

Hi: 14 Me: 12 Lo: 10

dB(A)

mm

Unit:287 817 620 Panel:8 1055 680

Internal thermostat for fan motor.

Frost protection thermostat

Models

FDTW28KXE6

FDTW45KXE6

FDTW56KXE6

2.8

5.6

3.2

1 phase 220-240V 50Hz/220V 60Hz

Electronic Expansion Valve

Direct line starting

Possible

Rubber sleeve (for fan motor)

Polyurethane foam

Flare piping

Connectable with VP20(I.D.20mm, O.D.26mm)

Necessary (both Liquid & Gas lines)

Mounting kit, Drain hose

Decorative Panel

Thermostat by electronics

mm(in)

Wired remote control switch (Optional:RC-E3)

Wireless kit (Optional:RCN-KIT3-E)

Hi: 39 Me: 34 Lo: 32

Louver fin & inner grooved tubing

6.3

4.5

5.0

Item

Indoor air temperature

Outdoor air temperature

Standards

ISO-T1

Operation

DB

WB

DB

WB

Cooling*

1

27

Heating*

2

20

19

35

7

24

6

Turbo fan 1

Nominal cooling capacity*

1

Nominal heating capacity*

2

Power source

Net weight

Starting method

Outside air intake

Air filter, Q'ty

Shock & vibration isolator

Insulation (noise & heat)

Room temperature control

Connecting method

Drain hose

Insulation for piping

Accessories

Optional parts

Motor

Air flow(Standard)

Exterior dimensions

Height Width Depth

Refrigerant equipment

Heat exchanger

Operation control

Operation switch

Installation data

Refrigerant piping size

Noise level

Safety equipment

(1) The data are measured at the following conditions.

Notes

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard.

ISO-T1 "UNITARY AIR-CONDITIONERS"

Decorative Panel model (Optional)

Refrigerant control

Air handling equipment

Fan type & Q'ty

Item

Model

FDTW28, 45, 56 type

TW-PSA-24W-E

Panel Part No.

Liquid line: 6.35(1/4")

Gas line: 9.52(3/8")

Liquid line: 6.35(1/4")

Gas line: 12.7(1/2")

Pocket plastic net 1(Washable)

Drain pump

Built-in Drain pump

(c)

Ceiling cassette-2 way type (FDTW)

Summary of Contents for FDC112KXEN6

Page 116: ... 112 4 Sensible heat capacity ...

Page 117: ... 113 ...

Page 118: ... 114 ...

Page 119: ... 115 ...

Page 120: ... 116 ...

Page 121: ... 117 ...

Page 122: ... 118 ...

Page 123: ... 119 ...

Page 124: ... 120 ...

Page 125: ... 121 ...

Page 126: ... 122 ...

Page 127: ... 123 ...

Page 128: ... 124 ...

Page 129: ... 125 ...

Page 130: ... 126 ...

Page 131: ... 127 ...

Page 132: ... 128 ...

Page 133: ... 129 ...

Page 134: ... 130 ...

Page 135: ... 131 ...

Page 136: ... 132 ...

Page 137: ... 133 ...

Page 138: ... 134 ...

Page 139: ... 135 ...

Page 140: ... 136 ...

Page 141: ... 137 ...

Page 142: ... 138 ...

Page 143: ... 139 ...

Page 144: ... 140 ...

Page 145: ... 141 ...

Page 146: ... 142 ...

Page 147: ... 143 ...

Page 148: ... 144 ...

Page 149: ... 145 ...

Page 150: ... 146 ...

Page 151: ... 147 ...

Page 152: ... 148 ...

Page 153: ... 149 ...

Page 154: ... 150 ...

Page 155: ... 151 ...

Page 156: ... 152 ...

Page 157: ... 153 ...

Page 158: ... 154 ...

Page 159: ... 155 ...

Page 160: ... 156 ...

Page 161: ... 157 ...

Page 162: ... 158 ...

Page 163: ... 159 ...

Page 164: ... 160 ...

Page 165: ... 161 ...

Page 166: ... 162 ...

Page 167: ... 163 ...

Page 168: ... 164 ...

Page 169: ... 165 ...

Page 170: ... 166 ...

Page 171: ... 167 ...

Page 172: ... 168 ...

Page 173: ... 169 ...