–

140

–

'19 • KX-SM-318

Precau

tions for s

a

fety

Read

th

e

se "

Precau

tions for s

a

f

e

ty" c

are

f

ull

y b

e

fo

re

st

ar

tin

g

d

i

s

a

ssemb

l

y wor

k

a

nd do

i

t in th

e

pro

pe

r way

.

W

h

e

n d

i

s

a

ssemb

li

n

g,

b

e

sur

e

to t

u

rn off th

e

p

ow

e

r. Wh

e

n d

i

sass

e

mb

li

n

g

th

e

elec

trica

l

c

om

p

on

e

nts,

c

h

ec

k th

e

elec

trica

l

wirin

g

di

agra

m.

T

h

e

elec

tr

ical

c

om

p

on

e

nts

are

u

n

de

r h

ig

h vo

l

ta

ge

by th

e

o

pera

tion of th

e

boost

e

r

capaci

tor.

Full

y

di

sch

arge

th

e

capaci

tor b

e

for

e

c

omm

e

n

ci

n

g

a r

epai

r wor

k.

Fa

ilure

to obs

e

rv

e

th

i

s w

ar

n

i

n

g

c

o

ul

d r

e

su

l

t

i

n

elec

tri

c

sho

ck.

W

h

e

n parts of r

e

f

rigera

nt

c

y

cle

i

s d

i

s

a

ssemb

led

by w

eldi

n

g,

b

e

sur

e

to wo

rk

aft

e

r co

llec

tin

g

a r

e

f

rigera

nt

,

i

f th

e

r

e

f

rigera

nt

i

sn

'

t

c

o

llec

t

ed,

th

e

u

n

i

t m

ig

ht

expl

o

de.

Be

sur

e

to

c

o

llec

t r

e

f

rigera

nt w

i

thout spr

eadi

n

g

i

t

i

n th

e

a

ir.

T

h

e

se

c

ont

e

nts

are

an

exa

m

ple.

Pl

eas

e

r

e

f

e

r to

a

s

i

m

il

ar

pa

rt of

ac

t

ual

u

n

i

t.

1. T

o remov

e

the s

e

rv

ice

p

a

n

el

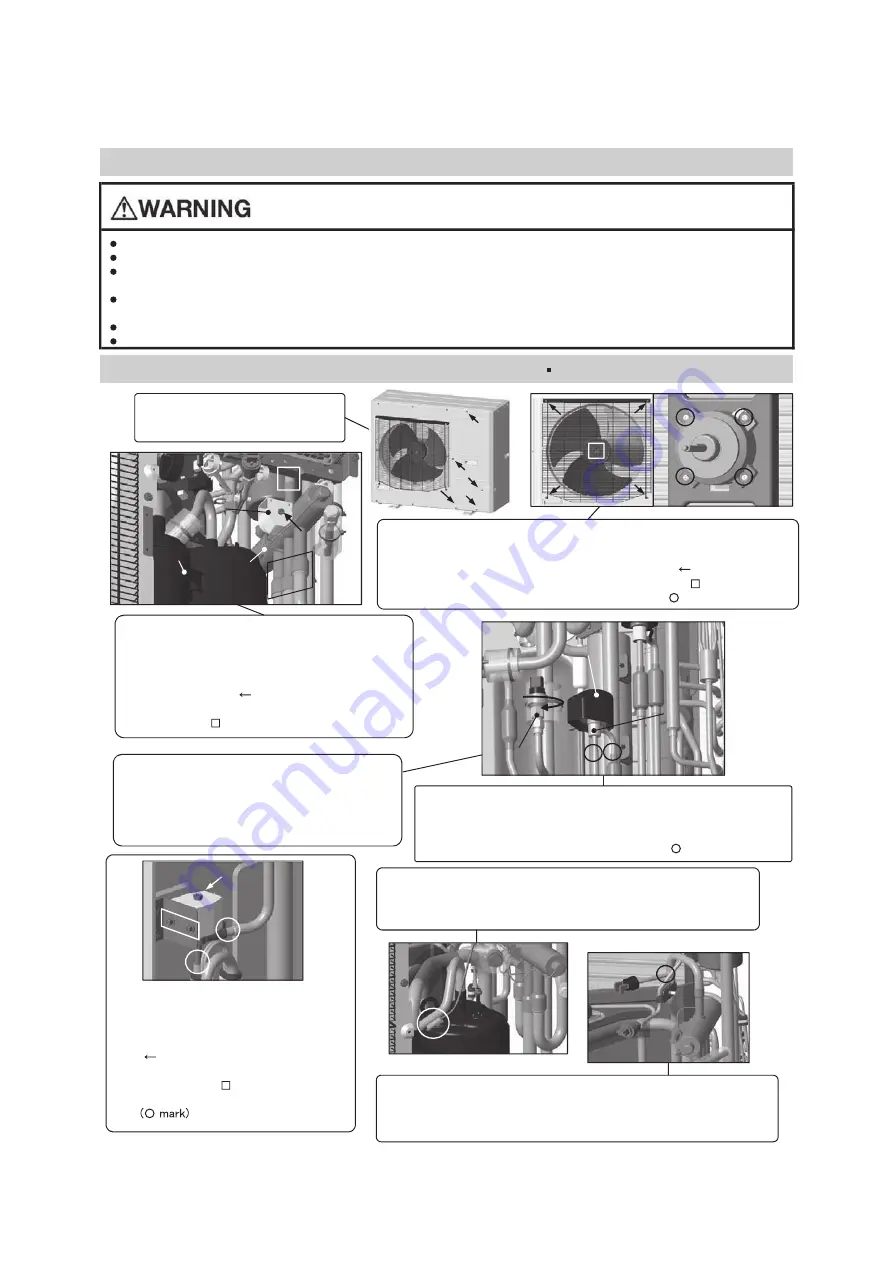

(1) Remove 5 service pa

nel fi

screws and remove it.

2. T

o remov

e

the f

a

n moto

r

(F

M)

(1) Remove the service panel.(See No.1)

(2) Disconnect the motor connector(FMxx or CNFxx) on PCB in control box.

(3) Remove 4 fan guard

fixing scr

ews and remove it.( mark)

(4) Remove the propeller fan

fixing

nut and remove it.( mark)

(5) Remove 4 fan motor

fixing

nuts and remove it.( mark)

3. T

o remov

e

the 4

-

w

a

y va

l

ve (

20S)

(1) Remove the service panel.(See No.1)

(2) Disconnect the coil of 4-way valve connector

(CNNx or CNS,CN20S) on PCB in control box.

(3) Remove the coil of 4-way valv

e fi

xing screw

and remove it.( mark)

(4) Remove welded part of 4-way valve by

welding. ( mark)

4

. T

o remov

e

the

l

ow

pre

ssu

r

e s

e

nsor (

PSL)

(1) Remove the service panel.(See No.1)

(2) Disconnect the PSL connector(CNLx or CNPS)

5. T

o remov

e

the

el

ect

r

onic

expa

ns

i

on va

l

ve (

EEV)

)

1

.

o

N

e

e

S

(.

l

e

n

a

p

e

c

i

v

r

e

s

e

h

t

e

v

o

m

e

R

)

1

(

.

x

o

b

l

o

r

t

n

o

c

n

i

B

C

P

n

o

(3) Turn PSL to the le

ft

and remove it.

(2) Disconnect the EEV connector(CNEEVx) on PCB in control box.

(Double spanners are needed.)

(3) Remove the coil of EEV by pull out on the top.

(4) Remove welded part of EEV by welding.( mark)

6. T

o remov

e

the temperature sensors (

exa

m

ple

"

T

ho

-D1

")

(1) Remove the service panel.(See No.1)

(2) Disconnect the Tho-D1 connector(CNTH) on PCB in control box.

(3) Pull out the temperature sensors "Tho-D1" from the sensor holder.

7. T

o remov

e

by

pa

ss v

al

ve (

SV)

(1) Remove the service panel.(See No.1)

(2) Disconnect the SV connector

on PCB in control box.

(3) Remove the coil of SV

fixing scr

ews.

( mark)

(4) Remove 2 c

oil of SV fi

xing screws

and remove it.( mark)

8. T

o remov

e

the high

pre

ssur

e

swit

c

h (

63H)

(5) Remove welded part of SV by welding.

(1) Remove the service panel.(See No.1)

(2) Disconnect the 63H connector(CNH or CNQx) on PCB in control box.

(3) Remove welded part of high pressure switch by welding.

DISASSEMBLY

PROCEDURE

PROCEDURE

&

PICTURE

S

(FDC

SCM

s

erie

s)

C

om

pre

sso

r

4

-

w

a

y v

al

v

e

C

o

il

of 4

-

w

a

y valv

e

EEV

C

o

il

of

EEV

PSL

6

.

OUTDOOR UNIT DISASSEMBLY PROCEDURE

6. OUTDOOR UNIT DISASSEMBLY PROCEDURE

Summary of Contents for FDC121KXZEN1

Page 159: ... 158 19 KX SM 318 ...

Page 161: ... 160 19 KX SM 318 ...

Page 162: ... 161 19 KX SM 318 ...