–

27

–

‘19 • KX-SM-318

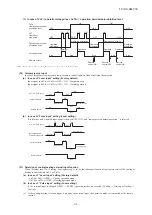

(c) Fan control during heating

During heating, fan speed is controlled in accordance with the low pressure (sensed by PSL).

(i) Initial fan speeds are as follows.

• Outdoor fan initial speed during heating

Model

Speed

All models

6th speed

(ii) During normal operation, the speed is changed in accordance with the low pressure value.

(4)

Defrost operation

• Temperature condition of defrost operation

(a) Starting conditions

Defrost

following conditions.

(i) When 33 minutes of cumulative compressor operation time has passed since heating operation started.

(ii) When 33 minutes of cumulative compressor operation time has passed since defrost operation ended.

(iii) When 8 minutes has passed since the compressor turned ON from OFF status.

(iv) When 8minutes has passed since one outdoor fan turned ON from OFF status.

(v) After all abo

①

When the outdoor heat exchanger temperature (sensed by Tho-R) and the ambient air temperature (sensed by

Tho-A) dropped below the defrost operation start temperature in Fig. 1 for 30 seconds continuously

②

When the suction pressure saturated temperature calculated by the low pressure (sensed by PSL) and the ambient

air temperature (sensed by Tho-A) dropped below the defrost operation start temperature in Fig. 2 for 30 seconds

continuously

TR: Heat exchanger temperature (°C)

TA: Ambient air temperature (°C)

TA: Ambient air temperature (°C)

Fig. 1

Cold region

Standard

(Factory setting)

Defrost operation start zone

-2

-6

-15

-19

-21

-25

-20

-15

6

Without J15

Cold region specification

With J15

SST: Suction pressure saturated temperature (°C)

Fig. 2

Cold region

Standard

(Factory setting)

Defrost operation start zone

-6

-10

-19

-23

-25

-29

-20

-15

6

Without J15

Cold region specification

With J15

(b) Ending conditions

Defrost operation stops when a

(i) When 12 minutes has passed since defrost operation started

(ii) When the outdoor heat exchanger temperature (sensed by Tho-R) is detected 12°C or higher continuously for 10

seconds

(iii) When it has detected the high

pressure (HP) ≥ 3.0MPa

(5) Protective control

(a) Discharge pipe temperature control

If the discharge pipe temperature exceeds 105°C, compressor speed is reduced to suppress the rising of discharge pipe

temperature.

(i) If the discharge pipe temperature sensor detects 115°C or higher for 2 seconds continuously, it makes compressor

stopped. And if this anomaly occurs 5 times within 60 minute, it makes the unit anomalous stop. (E36-1)

(ii) If the discharge overheat sensor (Td-DST) detects 5degC or lower for 10 minutes continuously, it makes compressor

And if this anomaly occurs 3 times within 60 minutes, it makes the unit anomalous stop. (E36-3)

(b) High pressure control

(i) Compressor rotation speed protection control

①

If high pressure sensor (PSH) detects 3.70MPa or higher, it makes compressor rotaion speed decreasing.

②

If high pressure sensor (PSH) still detects 3.70MPa or higher 5 seconds after

①

control, it makes compressor

rotation speed decreasing more.

③

If high pressure sensor (PSH) detects lower than 3.70MPa, this protective control is released.

(ii) High pressure protective control

If high pressure switch (63H1) is activated or if high pressure sensor (PSH) detects 4.14MPa or higher for 10

seconds continuously, it makes compressor stopped (High pressure anomaly).

And if this anomaly occurs 5 times within 60 minute, it makes the unit anomalous stop.(E40)

(c) Low pressure control

(i) Compressor rotation speed protection control

①

If low pressure sensor (PSL) detects 0.18MPa or lower for 10 seconds continuously, it makes compressor

rotaion speed decreasing.

②

If low pressure sensor (PSL) still detects 0.18MPa or lower 30 seconds after

①

control, it makes compressor

rotation speed decreasing more.

③

If low pressure sensor (PSL) detects higher than 0.236MPa, this protective control is released.

(ii) Low pressure protective control

If low pressure sensor (PSL) detects 0.134MPa or lower for 30 seconds continuously, or if it detects 0.003MPa or

lower for 5 seconds continuously, it makes compressor stopped (Low pressure anomaly).

And if this anomaly occurs 5 times within 60 minutes, it makes the unit anomalous stop.(E49)

(d) High pressure ratio protective control

①

If pressure ratio is 8.0 or higher, it makes compressor rotaion speed decreasing.

②

If pressure ratio is 8.0 or higher 60 seconds after

①

control, it makes compressor rotation speed decreasing more.

③

If pressure ratio is 7.9 or lower, this protective control is released.

(e) Over-current protection control (Current safe)

(i) Compressor capacity control

①

Compressor speed is controlled by detecting the inverter’s T-phase current or secondary current.

②

The control is changed at every ambient air temperature zone.

Ambient air temperature (ºC)

[Fig. 1]

Zone D

Zone C

Zone B

Zone A

34

36

38

40

43

45

Summary of Contents for FDC121KXZEN1

Page 159: ... 158 19 KX SM 318 ...

Page 161: ... 160 19 KX SM 318 ...

Page 162: ... 161 19 KX SM 318 ...