–

65

–

'18 • KX-SM-292

2.3 Contents of troubleshooting

(a) List of inspection displays

1) Indoor and outdoor units

Remote

control

error code

7-segment

display

Name of inspection

Classification

Page

E1

–

Remote control communication error

Communication error

81

E2

–

Duplicated indoor unit address

Address setting error

82

E3

–

Outdoor unit signal line error

Address pairing setting error

83

E5

–

Communication error during operation

Communication error

84

E6

–

Indoor unit heat exchanger temperature sensor anomaly (Thi-R) Sensor wire breakage

85

E7

–

Indoor return air temperature sensor anomaly (Thi-A)

Sensor wire breakage

86

E9

–

Drain trouble

System error

87

E10

–

Excessive number of indoor units (more than 17 units) by

controlling one remote control

Communication error

88

E12

–

Address setting error by mixed setting method

Address setting error

89

E16

–

Indoor fan motor anomaly (FDT series)

DC fan motor error

90

–

Indoor fan motor anomaly (FDK series)

DC fan motor error

91

E19

–

Indoor unit operation check drain pump motor check mode anomaly Setting error

92

E28

–

Remote control temperature sensor anomaly (Thc)

Sensor wire breakage

93

E30

E30

Unmatch connection of indoor and outdoor unit

System error

94

E31

E31

Duplicated outdoor unit address No.

Address setting error

95

E32

E32

Open L3 Phase on power source at primary side

Site setting error

96

E36

E36-1

Discharge pipe temperature error (Tho-D1)

System error

97

E36-3

Liquid flooding anomaly

System error

98

E37

E37-1, 2

E37-5, 6

Outdoor unit heat exchanger temperature sensor (Tho-R)

and subcooling coil temperature sensor (Tho-SC, -H)

anomaly

Sensor wire breakage

99

E38

E38

Outdoor air temperature sensor anomaly (Tho-A)

Sensor wire breakage

100

E39

E39-1

Discharge pipe temperature sensor anomaly (Tho-D1)

Sensor wire breakage

101

E40

E40

High pressure anomaly (63H1-1 activated)

System error

102

E41 (E51) E41 (E51)-1 Power transister overheat

System error

103

E42

E42-1

Current cut (CM1)

System error

104

E43

E43-1

E43-2

Excessive number of indoor units connected, excessive total

capacity of connection

Site setting erro

E45

E45-1

Communication error between inverter PCB and outdoor unit

control (PCB)

Communication error

E46

E46

Mixed address setting methods coexistent in same network

Address setting error

E48

E48-1

E48-2

Outdoor unit DC fan motor anomaly

DC fan motor error

E49

E49

Low pressure anomaly

System error

109

E53/E55

E53/E55-1 Suction pipe temperature sensor anomaly (Tho-S),

Under-dome temperature sensor anomaly (Tho-C1)

Sensor wire

breakage

110

E54

E54-1

E54-2

High pressure sensor anomaly (PSH)/Low pressure sensor

anomaly (PSL)

Sensor wire

breakage

111

E56

E56-1

Power transitor temperature sensor anomaly (Tho-P1)

Sensor wire breakage

112

E58

E58-1

Anomalous compressor by loss of synchronism

System error

113

E59

E59-1

Compressor startup failure (CM1)

System error

114

E60

E60-1

Rotor position detection failure (CM1)

System error

115

E63

E63

Emergency stop

Site setting error

2)

Option control in-use

SL1N-E

SL2NA-E

SL4-AE/BE

Indoor unit

control PCB

Outdoor unit

control PCB

Location of

trouble

Description of trouble

Repair

method

Error

code

Red

LED

Red

LED

Green

LED

Red

LED

Green

LED

E75

Keeps

flashing

Stays

OFF

Keeps

flashing

Stays

OFF

Keep

flashing

・

Communication enor (Deflective comm-

unication circuit on the main unit of

SL1N-E, SL2NA-E or SL4-AE/BE)

Replacement

SL1N-E

SL2NA-E

SL4-AE/BE

106

107

105

108

116

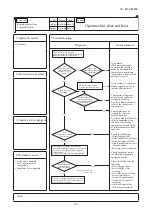

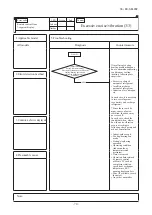

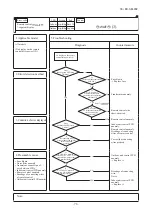

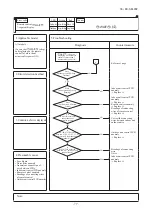

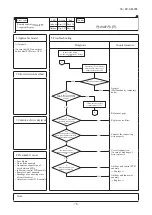

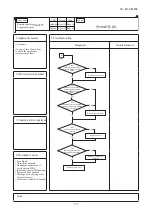

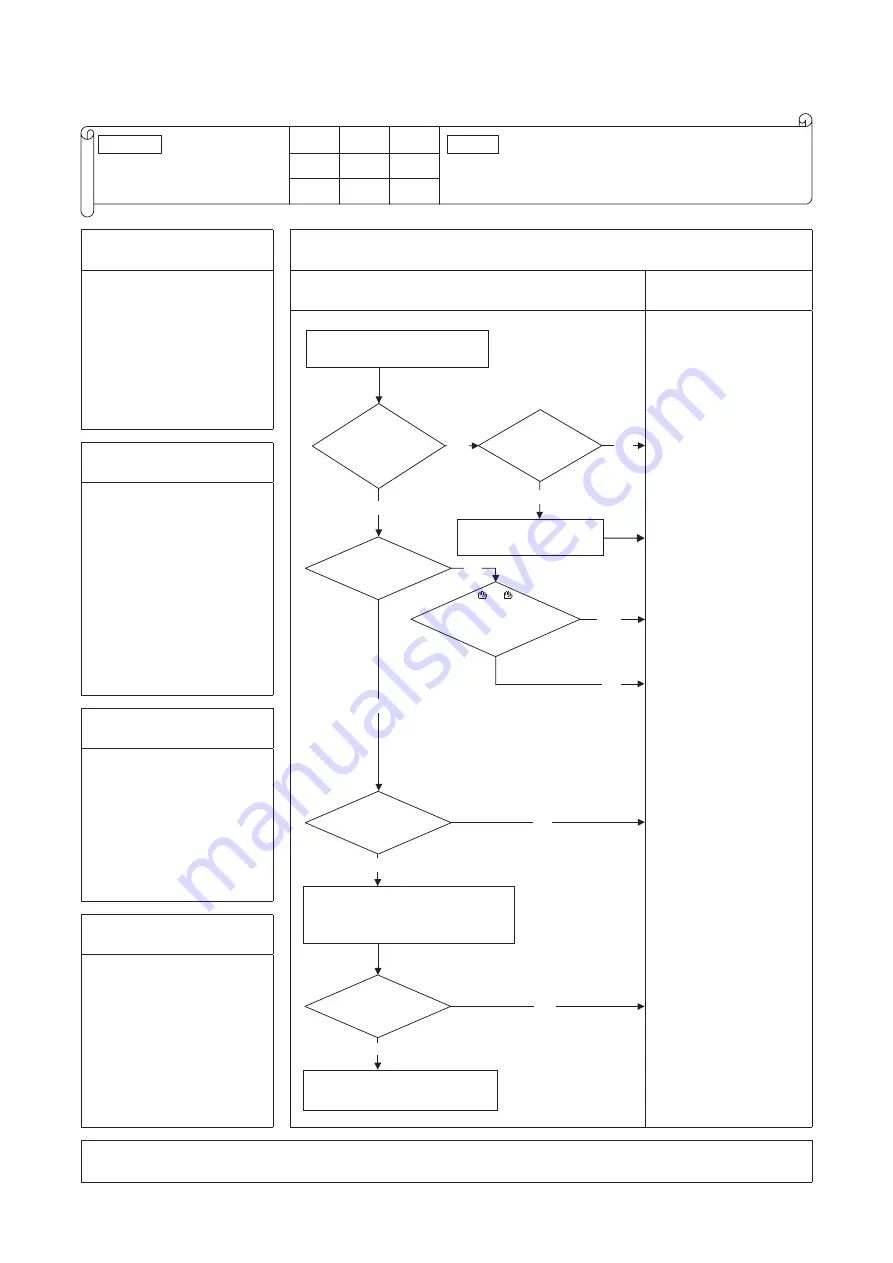

(b)

Troubleshooting

Error code

Remote control:

7-segment display:

LED

Green

Red

Indoor

Outdoor

Content

None

Operates but does not cool

Keeps flashing Stays Off

Keeps flashing Stays Off

1. Applicable model

5. Troubleshooting

All models

Diagnosis

Countermeasure

NO

YES

YES

NO

YES

YES

YES

NO

NO

NO

YES

NO

Check the indoor fan operation

Check the temperature difference between

return and suction air of indoor unit

Mistake in model selection.

Calculate heat load once more.

Check following operation control function.

. Control for determing compressor rotation speed

. Protective control by controlling compressor

rotation speed

Which control is appropriate to this phenomenon

The unit is operating normally, but is operating

under the protective control of compressor or

other respective components

Is the

temperature differnce

between return and

suction air 10-20ºC at

cooling?

Does the

heat load increase after

installtion?

Is the compressor

operating?

Is the

compressor rotation

speed low?

Is the

operating conditions of

indoor/outdoor unit

under rated condition?

" WAIT "

message is displayed [for

3 seconds] when performing

cooling, defumidifying or heating

operation from remote

control?

Note (1) Outdoor: 35ºC

Indoor : 27ºCDB/19ºCWB

It is normal.

(This unit is designed to

start in the soft start mode

by detecting the compressor

under-dome temperature

when it restart after power

reset.)

It is necessary to replace to

higher capacity unit or to

install additional unit.

Compressor refrigerant oil

protective control at starting

is activated.

For the contents of control, refer

to the compressor start control.

Compressor may be stopped

by the error detection control.

For the contents of control,

refer to anomalous stop

control by controlling

compressor rotation speed

of microcomputer control

function.

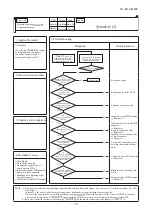

Check the followings

• Minor clogging of filter

• Minor fouling of heat exchanger

• Minor short-circuit of air

flow

• Slightly insufficient or excessive

refrigerant amount

• Poor compression of compressor

Check suspicious points

considering appropriate

operation control.

Check the followings for

reference

• Severe clogging of filter

• Severe clogging of heat

exchanger

• Severe short-circuit of

air flow

• Severely insufficient or

excessive refrigerant

amount

• Under protective control of

compressor

• Indoor unit fan tap setting

• Valid setting of silent mode

2. Error detection method

3. Condition of error displayed

4. Presumable cause

• Poor compression of

compressor

• Expansion valve anomaly

Note:

Summary of Contents for FDC224KXZME1

Page 169: ... 168 18 KX SM 292 PHA012D402 ...

Page 170: ... 169 18 KX SM 292 Screw ...

Page 171: ... 170 18 KX SM 292 ...

Page 172: ... 171 18 KX SM 292 ...