–

67

–

'18 • KX-SM-292

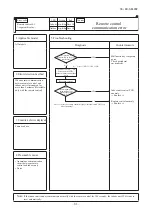

Error code

Remote control:

7-segment display:

LED

Green

Red

Indoor

Outdoor

Content

None

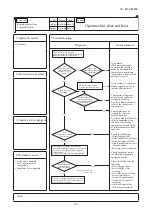

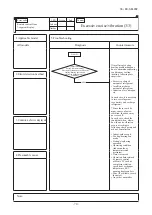

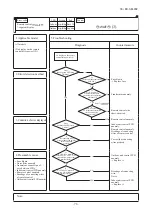

Operates but does not heat

Keeps flashing Stays Off

Keeps flashing Stays Off

1. Applicable model

5. Troubleshooting

All models

Diagnosis

Countermeasure

NO

YES

YES

NO

YES

YES

YES

NO

NO

NO

YES

NO

Check the indoor fan operation

Check the temperature difference between

return and suction air of indoor unit

Mistake in model selection.

Calculate heat load once more.

Check following operation control function.

. Control for determing compressor rotation speed

. Protective control by controlling compressor

rotation speed

Which control is appropriate to this phenomenon

The unit is operating normally, but is operating

under the protective control of compressor or

other respective components

Is the

temperature differnce

between return and

suction air 10-30ºC at

heating?

Does the

heat load increase after

installtion?

Is the compressor

operating?

Is the

compressor rotation

speed low?

Is the

operating conditions of

indoor/outdoor unit

under rated condition?

" WAIT "

message is displayed [for

3 seconds] when performing

cooling, defumidifying or heating

operation from remote

control?

Note (1) Outdoor: 7ºC

Indoor : 20ºC

It is normal.

(This unit is designed

to start in the soft start

mode by detecting the

compressor under-dome

temperature when it restart

after power reset.)

It is necessary to replace to

higher capacity unit or to

install additional unit.

Compressor refrigerant

oil protective control at

starting is activated.

For the contents of control,

refer to the compressor

start control.

Compressor may be

stopped by the error

detection control.

For the contents of control,

refer to anomalous stop

control by controlling

compressor rotation speed

of microcomputer control

function.

Check the followings

• Minor clogging of filter

• Minor fouling of heat exchanger

• Minor short-circuit of air flow

• Slightly insufficient or excessive

refrigerant amount

• Poor compression of compressor

Check suspicious points

considering appropriate

operation control.

Check the followings for

reference

• Severe clogging of filter

• Severe clogging of heat

exchanger

• Severe short-circuit of air flow

• Severely insufficient or

excessive refrigerant amount

• Under protective control of

compressor

• Indoor unit fan tap setting

• Valid setting of silent mode

2. Error detection method

3. Condition of error displayed

4. Presumable cause

• 4-way valve anomaly

• Poor compression of

compressor

• Expansion valve anomaly

Note:

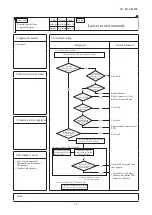

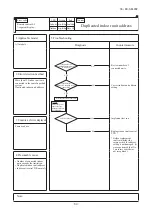

Error code

Remote control:

7-segment display:

LED

Green

Red

Indoor

Outdoor

Content

None

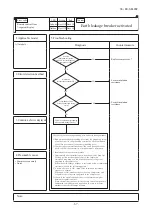

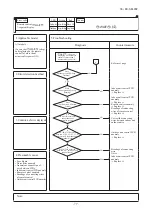

Earth leakage breaker activated

Stays Off Stays Off

Stays Off Stays Off

1. Applicable model

5. Troubleshooting

All models

Diagnosis

Countermeasure

NO

NO

Is insulation

of respective harnesses OK?

YES

Check of the outdoor unit grounding wire and earth leakage breaker

①

Run an independent grounding wire from the grounding screw

of outdoor unit to the grounding terminal on the distribution

panel. (Do not connect to another grounding wire.)

②

In order to prevent malfunction of the earth leakage breaker

itself, confirm the conformity of high harmonic regulation.

* Insulation resistance of compressor

• Immediately after installation or when the unit has been left

for long period without power source, the insulation

resistance may drop to a few Mk

Ω

because of refrigerant

migrated in the compressor.

When the earth leakage breaker is activated at lower insulation

resistance, check the following points.

①

6 hours after power ON, check if the insulation resistance

recovers to normal.

When power ON, crankcase heater heat up compressor and

evaporates the refrigerant migrated in the compressor.

②

Check if the earth leakage breaker is conformed to higher

harmonic regulation or not.

Since the unit has inverter, it is necessary to use components

conformed to high harmonic regulation in order to prevent

malfunction of earth leakage breaker.

YES

Check the outdoor unit grounding

wire and earth leakage breaker

Is any hamess bitten

between pannel and casing

or etc.?

NO

YES

Are the

insulation resistance

and and coil resistance of

compressor OK?

Replace compressor. *

Secure insulation

resistance.

Secure insulation

resistance.

2. Error detection method

3. Condition of error displayed

4. Presumable cause

• Compressor anomaly

• Noise

Note:

Summary of Contents for FDC224KXZME1

Page 169: ... 168 18 KX SM 292 PHA012D402 ...

Page 170: ... 169 18 KX SM 292 Screw ...

Page 171: ... 170 18 KX SM 292 ...

Page 172: ... 171 18 KX SM 292 ...