–

142

–

'14 • KX-SM-221

The switch will continuously change the display indication to the next one in every 0.25 seconds when it is pressed for 0.75 seconds or longer.

If the Reset switch is pressed during an operation, the display indication returns to the one that was shown before the last Set switch operation.

Even if an indoor unit No. is changed in this mode, the registered indoor unit No. before address change mode is displayed when [I/U SELECTION

▼

] is shown.

When “SET COMPLETE” is shown, indoor unit No.’s are registered.

Selecting an indoor unit

to be changed address

Setting a new indoor unit No.

2

3

Setting a new outdoor unit No.

Ending the session

4

5

④

Pressing the switch will change the display indication cyclically to show the unit No.’s

of the indoor units connected to the remote control and the unit No.’s of the outdoor units

connected with them.

⑤

Then the address No. of the indoor unit to be changed is determined and the screen switches to the

display “ SET I/U ADD.”

⑥

Set a new indoor unit No. with the switch.

A number indicated on the display will increase or decrease by 1 upon pressing the

▲

or

▼

switch

respectively.

⑦

After selecting an address, press the Set switch. Then the address No.of the indoor unit is determined.

⑧

The display will indicate the determined indoor address No. for 2 seconds and then switch to the

“ SET O/U ADD.” screen.

A default value shown on the display is the current address.

⑨

Set a new outdoor unit No. with the switch.

A number indicated on the display will increase or decrease by 1 upon pressing the

▲

or

▼

switch

respectively.

⑩

After selecting an address, press the Set switch.

Then the address of the indoor unit and outdoor unit are determined.

⑪

If you want to continue to change addresses, return to step

④

.

⑫

If you want to end the session (and reflect new address settings)

In Step

⑩

, press the

▼

switch to select “END

▲

.”

If you have finished changing addresses, press the Set switch while “END

▲

” is shown. While new settings are being

transmitted, “SET COMPLETE” will be indicated. Then the remote control display will change to the normal state.

⑬

If you want to end the session (without reflecting new address settings)

Before you complete the present address setting session, press the “ON/OFF” switch.

Then the display is change to exit from this mode and switch the display to the normal state.

All address settings changed in the session will be aborted and not reflected.

[

I/U

002

]

(2sec)

[

I/U 002

]

(2sec lighting)

⇔[

SET O/U ADD.

]

(1sec)

⇔[

O/U

01

]

(Blink)

[

O/U

00

▲]

⇔[

O/U

01

]

⇔[

O/U

02

]

⇔ ・・・

⇔[

O/U

31

▼]

[

I/U 002

O/U 02

]

(2sec lighting)

→[

SELECT

]

(1sec lighting)

→[

I/U SELECTION

▼]

(lighting)

[

Press the switch

]

(1sec)

→[

SET COMPLETE

]

(2

〜

10sec

lighting)

[

END

▲]

→[

SET COMPLETE

]

(2

〜

10sec lighting)

→

Normal state

[

ON/OFF

]

→

Forced termination

[

I/U 001 O/U 01

▲」

⇔[

I/U 002

O/U 01

]

⇔[

I/U 003

O/U 01

]

⇔ ・・・

⇔[

I/U 016 O/U 01

▼」

[

SET I/U ADD.

]

(1sec)

→[

I/U 001

]

(Blink)

[

I/U

000

▲]

⇔[

I/U

001

]

⇔[

I/U

002

]

⇔ ・・・

⇔[

I/U

127

▼]

Turn on power to centralized control equipment after the addresses are determined.

Turning on power in wrong order may result in a failure to recognize addresses.

Item

Operation

Display

NOTICE

⑦

Set a new outdoor unit No. with the switch.

A number indicated on the display will increase or decrease by 1 upon pressing the

▲

or

▼

switch respectively.

[I/U 000

▲」

⇔

[I/U 001

]

⇔

[I/U 002

]

⇔ ・・・

⇔

[I/U 127

▼

]

[I/U 002] (2sec Lighting)

→

[ SET O/U ADD.] (1sec)

→

[O/U 01

] (Blink)

[I/U 001

O/U 01] (1sec)

→

[ SET I/U ADD.] (1sec)

→

[I/U

001

] (Blink)

④

Set a new indoor unit No. with the switch.

A number indicated on the display will increase or decrease by 1 upon pressing the

▲

or

▼

switch respectively.

Item

Operating procedure

(1) When single indoor unit is connected to the remote control.

Address change mode

To set a new indoor unit No.

To set a new outdoor unit No.

1

2

3

①

Press the AIR CON No. switch for 3 seconds or longer.

②

Each time when you press the switch, the display indication will be switched.

[O/U 00

▲

]

⇔

[O/U 01

]

⇔

[O/U 02

]

⇔ ・・・

⇔

[O/U 31

▼

]

Operation

Display

③

Press the Set switch when the display shows “CHANGE ADD.

▼

”

and then start the address change mode, changing the display indication to the “Indoor Unit No.

Setting” screen from the currently assigned address.

⑤

After selecting an address, press the Set switch, and then the indoor unit address No. is defined.

⑥

After showing the defined indoor address No. for 2 seconds, the display will change to the “Outdoor

Address No. Setting” screen.

The currently assigned address is shown as a default value.

⑧

After selecting an address, press the Set switch, and then the outdoor unit No. and the

indoor unit No. are defined.

[CHANGE ADD.

▼

]

[CHANGE ADD.

▼

]

⇔

[MASTER I/U

▲

]

[I/U 002 O/U 02] (2sec Lighting)

→

[SET COMPLETE] (2sec Lighting)

→

Returns to normal condition.

[I/U 002] (2sec)

●

7-segment display indication in automatic address setting

Code

Contents of a display

P30

P31

P32

P34

Code

Contents of a display

Unable to find any indoor unit that can be actually communicated with.

The number of the indoor units that can be actually communicated with is less

than the number specified in P33 on the 7-segment display panel.

The number of the indoor units that can be actually communicated with is

more than the number specified in P33 on the 7-segment display panel.

Starting address (P32) + Number of connected indoor units (P33) > 128

While some units are operating in the previous SL mode on the network, the

automatic address setting on multiple refrigerant systems is attempted.

Are signal lines connected properly without any loose connections?

Is power for indoor units all turned on?

Are signal lines connected properly without any loose connections?

Input the number of connected indoor units again.

Are signal lines connected properly without any loose connections?

Are the network connectors disengaged properly?

Input the number of connected indoor units again.

Input the starting address again.

Input the number of connected indoor units again.

Perform manual address setting.

Separate old SL setting unit from the network

Arrange all units to operate in the new SL.

Code

A00

A01

A02

A03

A04

Contents of a display

Please check

Contents of a display

Cause

Code

E2

E3

E11

E12

E31

E46

Duplicating indoor unit address.

Incorrect pairing of indoor-outdoor units.

Incorrect adderess setting of indoor units.

Address setting for plural remote controls.

Incorrect setting.

Duplicating outdoor unit address.

・

Incorrect manual address setting

・

Indoor unit address is set from plural remote controls.

・

Plural outdoor units are exist as same address in same network.

・

Automatic address setting and manual address setting are mixed.

・

Automatic address setting and manual address setting are mixed.

・

・

No master unit exists in combination outdoor unit.

Items that are to be set by the customer

Communication protocol

0: Previos SL mode

1: New SL mode

Polarity difinition

0: Network polarity not defined.

1: Network polarity defined.

AUX

During automatic address setting.

X: The number of indoor units recognized by the outdoor unit.

AUE

Indoor unit address setting is completed normally.

End

Polarity is defined. (Automatic address)

Completed normally.

Automatic address start

Input starting address

Specify a starting indoor unit address in automatic address setting.

(The communication protocol is displayed ; display only)

P33

Input number of connected indoor units

7-segment display indication in automatic address setting.

Address setting failure indication

Error indication

Setting value for allocation of external input function

Name

Purpose (Factory default)

Specification

Operating side connector

With external input terminals closed With external input terminals open

Permitted

Invalid

Heating

Valid

Valid

Test run start

Cooling

Valid

Valid

Valid

Valid

External input CnS1

External output CnZ1

External operation input (closed at shipping)

Spare output (External output)

Non-voltage contactor (DC12V)

DC12V output

J.S.T (NICHIATSU) B02B-XAKS-1-T (LF) (SN)

MOLEX 5566-02A-RE

Prohibited

Valid

Cooling

Invalid

Invalid

Normal

Heating

Invalid

Invalid

Invalid

Invalid

"0" : External operation input

"1" : Demand input

"2" : Cooling/heating forced input

"3" : Silent mode 1 *1

"5" : Outdoor fan snow guard control input

"6" : Test run external input 1 (equivalent to SW5-1)

"7" : Test run external input 2 (equivalent to SW5-2)

"8" : Silent mode 2 *2

"10" : AF periodic inspection display

"11" : AF error display

"12" : Building multi energy save control

By changing the allocation of external input functions (P07) on the 7-segment, functions of external input

terminals CnS1 can be selected. Inputting signals to external input terminals enable the following functions.

"0" : Operation output

"1" : Error output

"2" : Compressor ON output

"3" : Fan ON output

"4 – 9" : Spare

The external output function of CnZ1 can be changed by

changing the setting in P06 on the 7 segment display panel.

Control selecting method

Content of control

8. TEST OPERATION AND TRANSFER

7-2. Selection switching

*1 Control is switched when both the allocation of external input function (P07) and SW are changed.

(Example: To use CnS1 for the input of forced cooling mode, set P07 at 2 and SW3-7 at ON.)

*1 Valid/invalid is changed depending on outdoor temperature.

*2 It is always Valid, regardless of outdoor temperature.

SW setting on PCB

SW5-5

J13: Closed (Factory default), J13: Open

J14: Closed (Factory default), J14: Open

J15: Closed (Factory default), J15: Open

P

○○

on 7-segment

SW3-7 to ON=1 *1

SW5-1 to ON + SW5-2 to ON

SW5-1 to ON + SW5-2 to OFF

Cooling test run

Heating test run

Communication method selection ON: Previous SL communication, OFF: New SL communication

External input switching (CnS1 only) Closed: Level input, Open: Pulse input

Defrost recover temperature

Closed: normal, Open: cold weather district

Defrost start temperature

Closed: normal, Open: cold weather district

Outdoor unit fan snow protection control ON time setting - 30 sec (at shipping) 10, 30-600 sec

Silent mode setting 0 (at shipping) - 3: Capacity priority 4-7: Sound priority

Allocation of external output (CnZ1)

Allocation of external input (CnS1)

Pump down operation

Operation priority selection

SW4-7:OFF, SW4-8:OFF*1

80% (Factory default)

SW4-7:ON , SW4-8:OFF*1

60%

SW4-7:OFF, SW4-8:ON*1

40%

SW4-7:ON , SW4-8:ON*1

00%

ー

ー

ー

ー

ー

ー

ー

ー

ー

ー

ー

ー

Close the liquid operation valve on outdoor unit and set as follows:

(1) SW5-2 on PCB to ON

(2) SW5-3 on PCB to ON

(3) SW5-1 on PCB to ON

Forced cooling /heating mode

Set allocation of external

input function to “2” *1

Set allocation of external

input function to “1” *1

Demand control mode by inputting signal to external input terminal.

(J13 short-circuited: Level input, J13 open: Pulse input)

2: Priority by master unit’s setting operation mode

3: Priority of required major operation mode

0: First push priority (at shipping)

1: Last push priority

Outdoor unit fan snow protection control

0: Control disabled (at shipping) 1: Control enabled

P01

P02

P03

P05

P06

P07

Contents of control for outdoor unit can be changed with dipswitches on PCB and P

○○

on 7-segment indicator.

When changing P

○○

on 7-segment indicator, it can be set by holding down SW8 (7-segment indicator UP: Ones digit), SW9 (7-segment indicator UP: Tens digit) and SW7 (Data write/Enter).

7-4. Silent mode setting

●

Operating sound of outdoor unit can be reduced in the silent mode. Remember, however, larger the effect of silencing, the drop of operating capacity becomes larger.

●

The silent mode can be set with the following methods of (1) or (2).

<Setting method of silent mode>

(1) Setting from the external input terminal (CnS1) on the outdoor unit

STEP1: If the external input function (P07) is allocated to “3”: silent mode 1 or “8”: silent mode 2, and the external input terminal (CnS1) is shorted, it is set to the silent mode.

* Priority in operations varies depending on silent mode 1 or silent mode 2. Select either one depending on purposes.

Silent mode 1: Capacity priority.

Silent mode 2: Sound priority.

STEP2: Allocate the external input function (P05) to “0

〜

3” for silent mode 1 (Capacity priority) or “4

〜

7” for silent mode 2 (Sound priority). Larger the figure, the silencing effect

is larger. (Default setting is 0.)

(2) Setting by input from the remote control of indoor unit

If the signal of silent mode is transmitted from one of indoor units in the connection, it is set in the silent mode.

It is operated in the silent mode, depending on the allocation to “0

〜

7” for the external input function (P05). Larger the figure, the silencing effect is larger. (Default setting is 0.)

If (P05) is set at 0

〜

3: Capacity priority.

If (P05) is set at 4

〜

7: Sound priority.

Note) If the settings (1) and (2) above are established simultaneously, the priority is given to operations from the remote control in (2).

If the settings of the silent mode and the demand control are established simultaneously, they are operated according to their lowest demands.

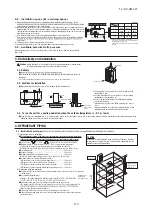

Signal line

Refrigerant pipe

Outdoor unit [01]

Outdoor unit [02]

Indoor unit

Indoor unit

Indoor unit

Indoor unit

Indoor unit

Indoor unit

Address change (available only with new SL)

・

Within a refrigerant system, indoor units are assigned addresses in the order they are recognized by the outdoor unit. Therefore, they are not necessarily assigned addresses in

・

Make sure that power has been turned on to all indoor units.

・

When addresses are set, you can have the registered indoor unit address No.’s and the outdoor unit address No. displayed on the remote control unit by pressing its Inspection switch.

・

Automatic address setting can be used for an installation in which plural indoor units are controlled from one remote control unit.

・

Once they are registered, addresses are stored in microcomputers, even if power is turned off.

・

If you want to change an address after automatic address setting, you can change it from the remote control unit with its “Address Change” function or by means of manual

setting. Set a unique address by avoiding the address assigned to other indoor unit on the network when the address is changed.

・

Do not turn on power to centralized control equipment until automatic address setting is completed.

・

When addresses are set, be sure to perform a test run and ensure that you can operate all indoor and outdoor units normally. Also check the addresses assigned to the indoor units.

Indoor unit

(

00

)

+01

Indoor unit

(

01

)

+01

Indoor unit

(

02

)

+01

Indoor unit

(

00

)

+04

Indoor unit

(

01

)

+04

Indoor unit

(

02

)

+04

Indoor unit

01

Indoor unit

02

Indoor unit

03

Indoor unit

02

Indoor unit

03

Indoor unit

04

Indoor unit

05

Indoor unit

06

Indoor unit

04

Indoor unit

05

Indoor unit

06

[

STEP1

]

[

STEP2

]

[

STEP3

]

[

STEP4

]

Outdoor unit [01]

Start [01]

Number [03]

Start [04]

Number [03]

Outdoor unit [02]

Outdoor unit [01]

Outdoor unit [02]

Outdoor unit [01]

Outdoor unit [02]

Indoor unit

01

Indoor No.SW

000

000

Outdoor No.SW

49

49

Indoor unit address setting

Outdoor unit address setting

Outdoor No.SW

49

00

〜

31

“Address Change” is used,

when you want to change an indoor unit address assigned with the “Automatic Address Setting” function from a remote control unit

.

Accordingly, the conditions that permit an address change from a remote control unit are as follows.

If “CHANGE ADD.

▼

” is selected with some addresses falling outside these conditions, the following indication will appear for 3 seconds on the

remote control ”INVALID OPER” .

Automatic address setting for multiple refrigerant systems installation

Automatic address setting for single refrigerant system installation

Polarity

setting

Specify the number of indoor units connected in the refrigerant system in

automatic address setting.

(1)

Make sure that a measurement between the power source terminal block and ground, when measured with a 500V megger, is greater than 1 M

Ω

.

When the unit is left for a long time with power OFF or just after the installation, there is possibility that the refrigerant is accumulated in the compressor and the

insulation resistance between the contact terminals for power source and grounding decreases to 1M

Ω

or around.

When the insulation resistance is 1M

Ω

or more, the insulation resistance will rise with crank case heater power ON for 6 hours or more because the refrigerant in the

compressor is evaporated.

(2) Check the resistance of the signal wire terminal block before power is turned on. If a resistance measurement is 100

Ω

or less, it suggests a possibility that power

cables are connected to the signal wire terminal block. (Please refer to 6-3. Standard resistance value.)

(3)

Be sure to turn on the crank case heater 6 hours before operation

.

After turning on the crank case heater, there is possibility that the compressor doesn't start operation unless the compressor temperature rises or the time mentioned

above is passed. (for protection of compressor)

If the 7 segment display shows the "dL

○

" and "

○○○

"( the rest of time 360

〜

001) alternately every 4 seconds, perform the test operation after the compressor

temperature rises by the turning on the crank case heater.

(4)

Make sure that the bottom of the compressor casing is warm

. (higher than outdoor tempe5°C)

(5) Be sure to fully open the operation valves (liquid and gas) for the outdoor unit.

Operating the outdoor unit with the valves closed may damage the compressor.

(6)

Check that the power to all indoor units has been turned on. If not, water leakage may occur

.

CAUTION

Make sure that the operation valves (gas and liquid) are full open before a test run. Conducing a test run with any of

them in a closed position can result in a compressor failure.

8-1. Before starting operation

7-5. Demand control setting

●

The demand control setting allows cutting the power peak, by suppressing the operating capacity of outdoor unit.

Demand ratio is the rate of the maximum capacity relative to the rated capacity.

●

When the load is low, the effect of demand control setting may be small and the power consumption may not be reduced so much.

Under the overload condition, it reduces also the rated maximum capacity so that it may reduce the capacity larger than the demand ratio.

●

The demand control can be set with the following methods of (1) or (2).

<Setting method of demand control>

(1) Setting from the external input terminal

To set the demand ratio, allocate the external input function (P07) to “1”: Demand input, and change the setting

of SW4-7 and SW4-8 on the PCB as follows while the external input terminal (CnS1) is open.

(2) Setting from the remote control

If the signal of peak cut ratio, by means of the peak cut timer, is received from the remote control of indoor unit, it is operated with the set demand ratio.

If peak cut signals are received from two or more indoor units, it is operated with the lowest demand ratio.

Note) If two or more settings of (1) and (2) above are established simultaneously, the priority is given to the demand of lowest ratio.

If the settings of the silent mode and the demand control are established simultaneously, they are operated according to their lowest demands.

SW4-7

SW4-8

Demand ratio (%)

OFF

OFF

80

ON

OFF

60

OFF

ON

40

ON

ON

0

(2) When plural indoor units are connected to the remote control.

When plural indoor units are connected, you can change their addresses without altering their cable connection.

Address change mode

1

①

Press the AIR CON Unit No. switch for 3 seconds or longer.

②

Each time when you press the switch, the display indication will be switched.

③

Press the Set switch when the display shows “CHANGE ADD.

▼

”

The lowest indoor unit No. among the indoor units connected to the remote control unit will be shown.

[

SELECT I/U

]

(1sec)

→[

I/U 001 O/U 01

▲]

(Blink)

[

CHANGE ADD

▼]

⇔[

MASTER I/U

▲]

[

CHANGE ADD

▼]

Item

Operation

Display

9. CAUTIONS FOR SERVICING (for R410A and compatible machines)

(1) To avoid mixing of different types of oil, use separate tools for each type of refrigerant.

(2) To avoid moisture from being absorbed by the refrigerant oil, the time for when the refrigerant circuit is open should be kept as short as possible. (Within 10 min. is ideal.)

(3) For other piping work, airtighteness testing , vacuuming, and refrigerant charging, refer to section 4, REFRIGERANT PIPING.

(4) Diagnostic Inspection Procedures

For the meanings of failure diagnosis messages, refer to the technical manual.

(5) 7-segment LED indication

Data are indicated when so chosen with the indication selector switch. For the details of indication, refer to the technical manual.

(6) Internal wiring

After maintenance, all wiring, wiring ties and the like, should be returned to their original state and wiring route, and the necessary clearance from all metal parts should be secured.

(2) Method of starting a test run for a cooling operation from an indoor unit: operate a remote control unit according to the following steps.

(a) Start of a cooling test run

○

Operate the unit by pressing the ON/OFF button.

○

Select the “COOLING” mode with the MODE button.

○

Press the TEST button for 3 seconds or longer.

The screen display will be switched from “Select with ITEM ”

→

“Determine with SET ”

→

“Cooling test run

▼

.”

○

When the SET button is pressed while “Cooling test run

▼

” is displayed, a cooling test run will start. The screen display will be switched to “COOLING TEST RUN.”

(b) Termination of a cooling test run

○

When the ON/OFF button or the “TEMP ” button is pressed, a cooling test run will be terminated.

(1) Test run from an outdoor unit.

Whether CnS1 is set to ON or OFF, you can start a test run by using the SW5-1 and SW5-2 switches provided on the outdoor unit PCB.

Set SW5-2 to ON for a cooling test run or OFF for a heating test run. (It is set to OFF at the factory for shipment)

Turning SW5-1 from OFF to ON next will cause all connected indoor units to start.

When a test run is completed, set SW5-1 to OFF.

Note: During a test run, an indoor unit cannot be operated from the remote control unit (to change settings). (“Under centralized control” is indicated)

▲

▼

●

Use the instruction manual that came with the outdoor unit to explain the operation method to the customer.

Ask the customer to keep this installation manual together with the operation manual of his indoor units.

●

Instruct the customer that the power should not be turned off even if the unit is not to be used for a long time. This will enable operation of the air-conditioner any time.

(Since the compressor bottom is warmed by the crank case heater, seasonal compressor trouble can be prevented.)

8-2. Test run

8-3. Transfer

Notes : for engineers undertaking piping or electrical installation work

When a test run is completed, make sure again that the electrical component box cover and the unit panel have been attached before you turn the unit over to the customer.