–

143

–

'14 • KX-SM-221

5.2 Method for connecting the accessory pipe

●

Be sure to use the accessory pipe to connect the operation valve on the gas side with the field pipe.

Be sure to ues the straight pipe (Procured at the field) shown in the table 1 applicable to the model

●

of outdoor unit.

●

When tightening the flare, connect the pipe securely by pressing the flared face of pipe against

the operation valve.

●

When brazing between the pipe in place and the attached pipe, confirm that no excessive force is

applied to the flare joint. Otherwise gas could leak from the flare joint.

●

Connect the attached pipe according to the following steps

①〜⑤

.

Referring to Table 2 and Table 3, prepare the straight pipe and the elbow in the field, which are

used in the construction examples

Ⓐ〜Ⓓ

applicable to the connecting direction.

Firstly, use the accessory pipe to assemble the connecting pipe assembly outside the outdoor unit.

(

As showm in the figure of connecting examples

Ⓐ〜Ⓓ.)

After assembling the connecting pipe, connect it to the operation valve on the gas side

inside the outdoor unit. Tighten the flare nut with appropriate torque.

After connection of the connecting pipe assembly to the operation valve on the gas side,

braze the connecting pipe assembly and the field pipe.

When connecting pipe contacts wiring, attach heat insulating material to the pipe in order to prevent

from contacting of the pipe and wiring. (If the wiring is rubber with the pipe and the cover of wiring

is teared, there is a risk of a short circuit or an electtric shock.

)

①

②

③

④

⑤

Proper torque

φ

19.05 100

〜

120N

・

m

About brazing

●

Be sure to braze while supplying nitrogen gas.

If no nitrogen gas is supplied, a large amount of impurity

(

oxidized film) will be generated, which may clog the capillary

tube and the expansion valve, resulting in fatal malfunction.

Table 2 Parts used for the connecting pipe assembly

Table 1 Pipe specification

(

m

)

h

t

g

n

e

l

)

y

a

w

e

n

o

(

e

n

il

t

n

a

r

e

g

ir

f

e

R

φ

22.22 x T1.0

φ

25.4 x T1.0 or

φ

28.58 x T1.0

●

Be sure to use pipes of 1

/

2H material, and wall thickness

above 1mm. (Pressure resistance of O-type pipe is not enough)

No.

Name

Quantity

Remark

Accessory pipe A

Straight pipe

①

Straight pipe

②

Elbow

1

2

3

4

1

1

1 or 0

1 or 0

Accessory

Procured at the field

Procured at the field

(

Not required for downward direction

)

Procured at the field

(

Not required for downward direction

)

Table 3 Length and specification of straight pipe

(

Procured in the field

)

Straight pipe

①

Straight pipe

②

400mm or more 192.5

〜

202.5mm 192.5

〜

202.5mm

-

105mm or more 155mm or more

210mm

370mm or more

Ⓐ

Downward

Ⓑ

Forward

Ⓒ

Rightward

Ⓓ

Backward

Heat insulating material is attached

to the accessory pipe with band.

When installing the heat insulating

material, cut the band and retrieve it.

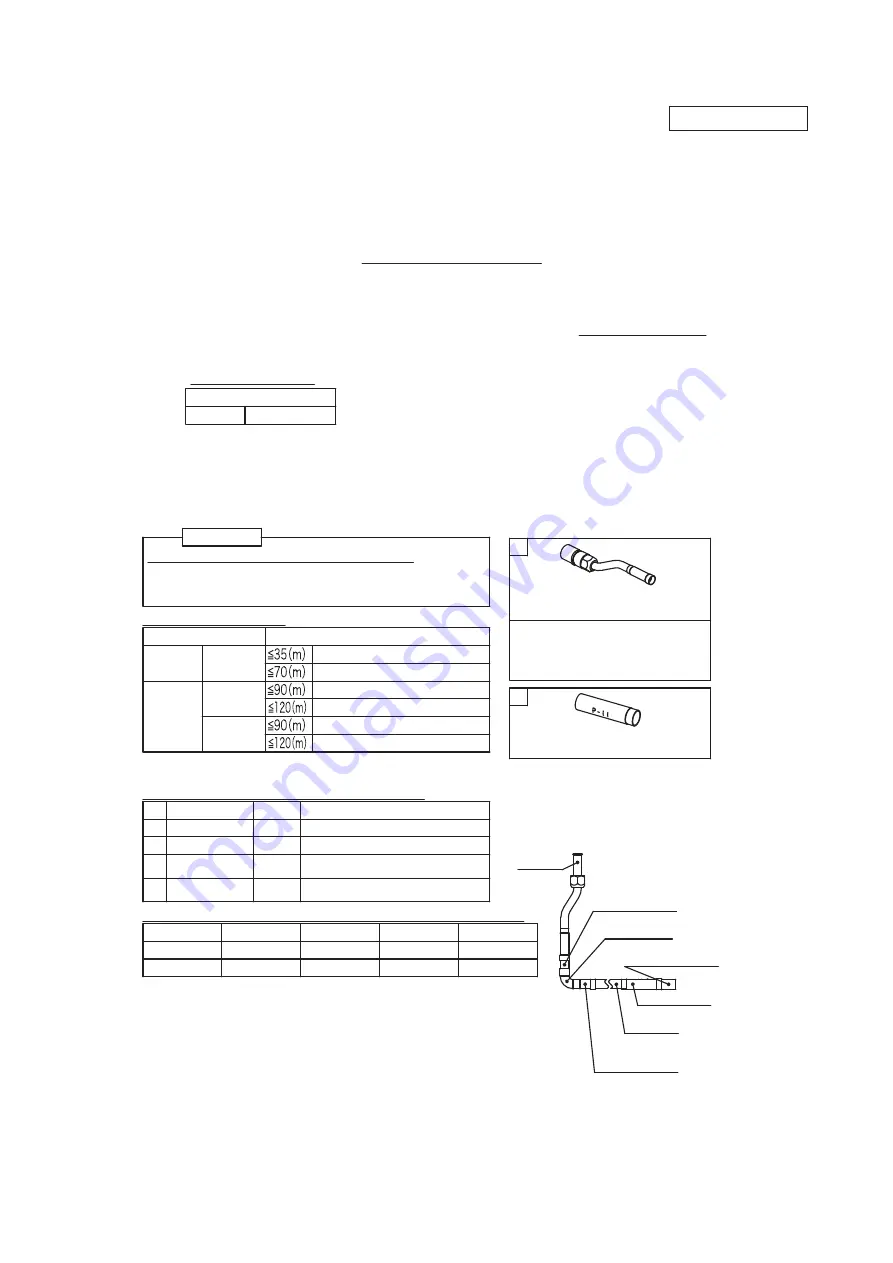

●

Branching pipe set can be used by

using the accessory pipe B.

When

φ

22.22

(

OD

)

size of the

indoor unit gas pipe is used, the

accessory pipe B is unnecessary.

A

B

Straight pipe

①

φ

22.22

(

OD

)

to be

procured locally

Straight pipe

②

φ

22.22

(

OD

)

to be

procured locally

Field piping

φ

22.22

(

OD

)

Branching pipe set

(

DIS-WB1G,DIS-TB1G

)

Elbow to be

procured locally

Accessory pipe B

250V

224KXZPE1

280KXZPE1

Single type

Multi type

φ

19.05 x T1.0

φ

22.22 x T1.0

φ

22.22 x T1.0

φ

25.4 x T1.0 or

φ

28.58 x T1.0

Accessory pipe A x 1 pc

(

Except 224KXZPE1

)

Accessory pipe B x 1 pc

(

Only use for 250V

)

※

In case of V-multi

(

In case of 250V

)

Accessory

pipe A

PSC012D028C