-

6

-

'09•KX-T-139

5

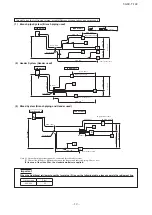

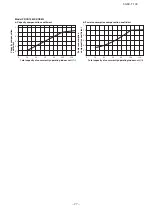

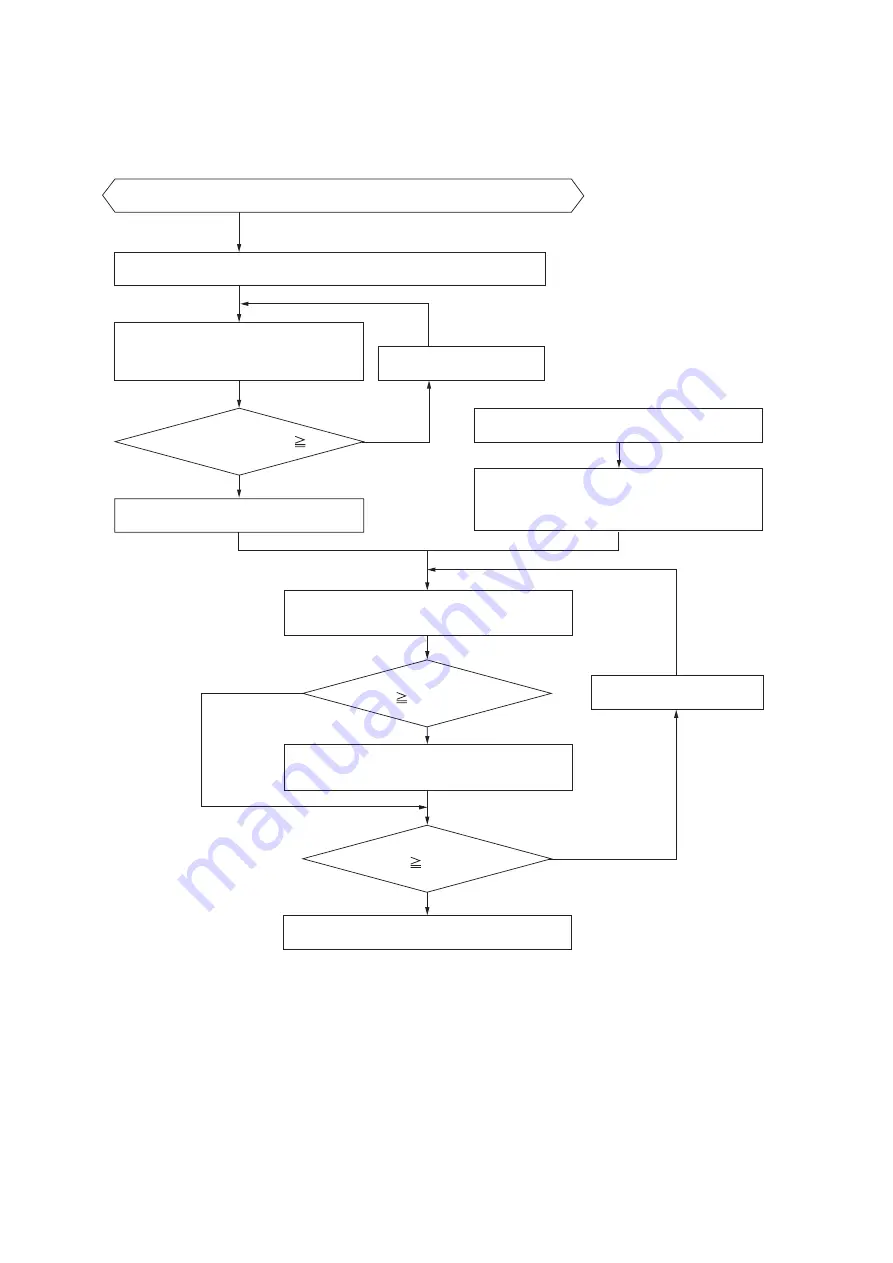

SELECTION CHART

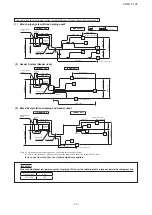

(1) Equipment selection flow

Indoor unit

capacity (tentative)

Indoor Load

Total indoor unit

capacity System Capacity

YES

YES

YES

NO

NO

NO

Select an indoor unit that matches the indoor load (tentative).

Calculate the total indoor unit capacity.

Indoor unit

capacity Indoor Load

Equipment selection complete.

Change the outdoor unit.

Calculate the temperature compensation,

then calculate the indoor unit capacity.

(See item (2) (a) for the calculation method.)

Calculate temperature compensation and piping

compensation, etc., then calculate the outdoor unit

capacity. (See item (2) (b) for the calculation method.)

Select the outdoor unit (tentative).

Calculate the system capacity

(See item (2) (c) for the calculation method.)

Calculate the indoor unit capacity.

(See item (2) (d) for the calculation method.)

Calculate the load for each room separately, then determine the indoor load.

Change the indoor unit.

Summary of Contents for FDCH1010CKXE6G

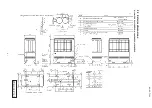

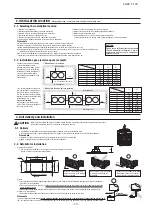

Page 8: ... 09 KX T 139 2 2 Exterior dimensions Models FDCH335CKXE6G K 400CKXE6G 450CKXE6G PCB003Z141 ...

Page 9: ... 09 KX T 139 Models FDCH504CKXE6G 560CKXE6G 560CKXE6G K 615CKXE6G 680CKXE6G PCB003Z142 ...

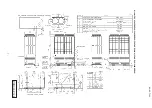

Page 10: ... 09 KX T 139 2 3 Electrical wiring Models All model PCB003Z139 ...

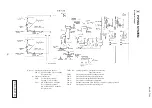

Page 41: ......

Page 42: ... 40 09 KX T 139 ...

Page 63: ... 09 KX T 139 Combination use PCB003Z587 61 ...

Page 64: ... 09 KX T 139 2 2 Exterior dimensions Models FDCH335CKXE6G K 400CKXE6G 450CKXE6G PCB003Z589 62 ...

Page 65: ... 09 KX T 139 Models FDCH504CKXE6G 560CKXE6G 560CKXE6G K 615CKXE6G 680CKXE6G PCB003Z590 63 ...

Page 66: ... 09 KX T 139 2 3 Electrical wiring Models All model PCB003Z588 64 ...