-

112

-

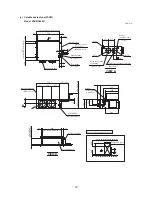

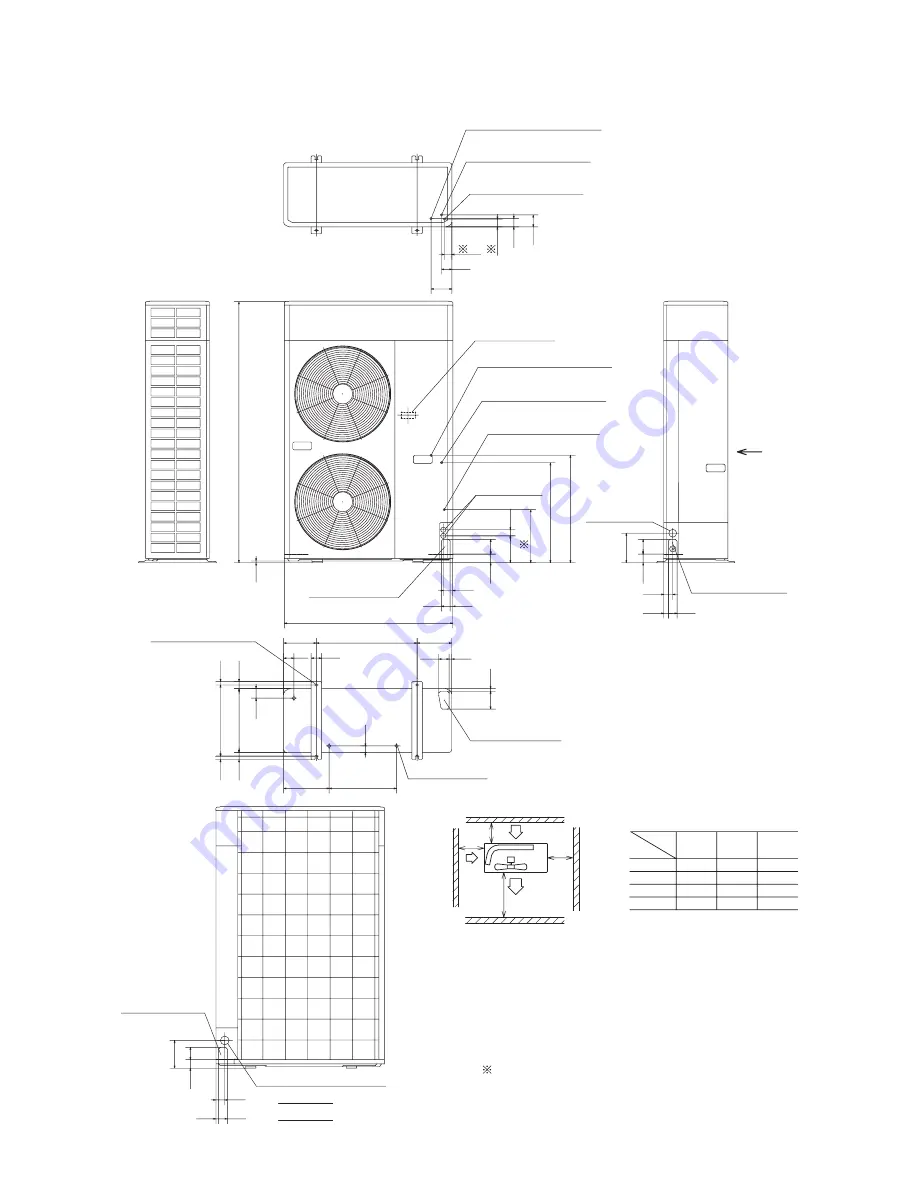

Model FDCVA1002HESAR

Unit: mm

Minimum allowable space to the obstacles

L1

L2

L3

Air outlet

Air inlet

Air inlet

Maintenance

space

L4

Mark

Installation

type

Unit : mm

L2

L3

L4

L1

300

150

5

Open

Open

Open

I

5

300

5

II

150

5

500

III

( )

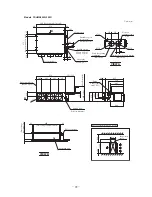

1505

10

55

15

50

970

50

619

576

306

155

85

35

69

60

120

48

52

27

50

170

50

85

50

15

50

50

160

70

370

410

20

20

40

40

55

60

262

388

38

580

190

200

103

15

60

15

60

44

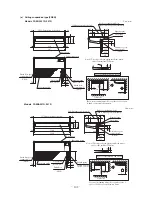

Terminal block

Liquid piping :

φ

9.52(3/8")

(Flare connecting)

Gas piping :

φ

19.05(3/4")

(Flare connecting)

Gas piping :

φ

25.4(1")

(Brazing connecting)

Liquid piping :

φ

9.52(3/8")

(Flare connecting)

Gas piping :

φ

19.05(3/4")

(Flare connecting)

Gas piping :

φ

25.4(1")

(Brazing connecting)

Opening for

electric wiring

Opening for piping

and electric wiring

Opening for piping

and electric wiring

Opening for piping

and electric wiring

Opening for piping

and electric wiring

Opening for

electric wiring

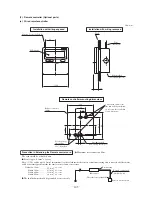

Holes for anchor bolt

Holes for drain

Opening for electric wiring

VIEW A

A

(M10

×

4 pcs.)

45

Notes

(1) It is prohibited to install in a space enclosed with walls at four sides.

(2) Unit must be secured with anchor bolts.

Anchor bolt should not protrude more than 15 mm above the surface.

(3) Where strong winds blow, the blow outlet must be oriented at right angle against the

wind direction.

(4) Secure a space of 1 m or more above the unit.

(5) Barrier standing in front of the blow outlet must be lower than the height of unit.

(6) Use the attached accessory piping for connection as the gas piping

φ

25.4(1

″

), and

connect it with the field piping.

(7) The dimensions show the connecting position of the

φ

25.4(1

″

) accessory piping

for connection.