-

192

-

b) Give the drain piping a descending grade (1/50-1/100) and never create

a bump to go over or a trap.

c) In connecting drain pipes, care must be taken so as not to apply force

to the unit side piping and fix the pipe at a point as close to the unit as

possible.

d) Do not create an air vent under any circumstances.

e) When drain piping is implemented for more than one unit, provide a

collecting main about 100 mm below the units’ drain outlets from which

it collects drain. Use a VP-30 or larger pipe for a collecting main.

f)

Do not fail to provide heat insulation at the following two points because

they can cause dew condensation and a resultant water leak.

7) Drain

socket

After a drain test is completed, apply a pipe cover (small: accessory) onto

the drain socket, cover the pipe cover (small), the clamp and part of the drain

hose with a pipe cover (large: accessory) and wrap it with a tape completely

without leaving any gaps.

(Cut pipe covers into appropriate shapes)

8)

Hard PVC pipes laid indoor

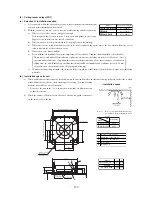

a) Since a drain pipe outlet can be raised up to 700 mm from the ceiling,

use elbows, etc. to install drain pipes, it there are obstacles preventing

normal drain pipe arrangement. When the drain pipe is raised at a point

far from a unit, it can cause an overfl ow due to a back fl ow of drain upon

stoppage, so arrange piping to keep the dimensions specifi ed in the il-

lustration shown on the left.

b) Install the drain pipe outlet where no odor is likely to be generated.

c) Do not lead the drain pipe into a ditch where the generation of harmful

gas such as sulfuric gas or fl ammable gas is expected. A failure to observe

this instruction may cause such harmful or fl ammable gas to fl ow into the

room.

1.5 m ~ 2 m

Suspension

bolts

Desceding slope

greater than 1/100

Insulation

material

No bump

Air vent

No trap

Not

touching

the water

As wide as possible

(about 100 mm)

VP30

Joint for VP-25

(not included)

Desceding slope

greater than 1/100

295 ~ 325 mm

100 mm or less

Drain hose

700 mm or less

Trapped air will

generate noises.

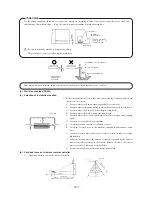

Drainage test

Check that water is draining thoroghly during test run, and that there are no water leaks from the joints and the drain pan.

The test has to be performed even if the unit is installed in the season when the unit is used for healting.

In a new house, perform the test before the ceiling is fitted.

• Using a water pump, pour about 1000 cc of water to the drain pan through

the blowing outlet.

• Check the transparent drain-out section of the drain hose for normal fl ow of

drainage.

* While observing the noise from the drain motor, test drain operation.

• Take off the drain plug to release the water. After the water is drained, place

the drain pulg back where it was.

* Be careful not to get splashed when pulling the drain plug.

Forced drain pump operation

♦

Set up from a unit side.

Turn power on after selecting the emergency operation mode with a setting on the indoor unit control PCB (SW9-3 ON) and

disconnecting the CnB connector on the board. Then, the drain pump will start a continuous operation 15 seconds later.

(Note: The blower will also start operation in tandem)

When a drain test is completed, reinstate the setting to cancel the emergency operation mode (SW9-3 OFF) and plug in the

CnB connector on the board.

(When electrical work is not completed, connect a convex joint to the drain pipe joint area, arrange an inlet and check leaks

and drain connections of the pipe)

Put the tip of the feed water pump

in the drain pan of the unit body

Drain plug