-

203

-

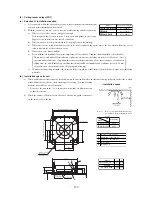

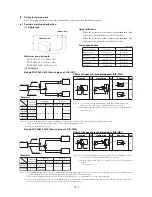

(5) Satellite ducted type (FDUM)

(i)

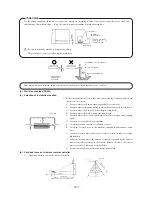

Selection of installation location

1) Avoid installation and use at those places listed below.

a) Places exposed to oil splashes or steam (e.g. kitchens and machine plants).

Installation and use at such places will incur deteriorations in the performance or corrosion with the heat exchanger or

damage in molded synthetic resin parts.

b) Places where corrosive gas (such as sulfurous acid gas) or inflammable gas (thinner, gasoline, etc.) is gnerated or remains.

Installation and use at such places will cause corrosion in the heat exchanger and damage in molded synthetic resin

parts.

c) Places adjacent to equipment generating electromagnetic waves or high-frequency waves such as in hospitals. Generated

noise may cause malfunctioning of the controller.

2) Select places for installation satisfying the following conditions and, at the same time, obtain the consent on the part of your

client user,

a) Places where chilled or heated air circulates freely. When the installation height exceeds 3m, warmed air stays close to

the ceiling. In such cases, suggest your client users to install air circulators.

b) Places where perfect drainage can be prepared and suffi cient drainage gradient is available.

c) Places free from air disturbances to the return air port and supply hole of the indoor unit, places where the fi re alarm may

not malfunction to short circuit.

d) Places with the environmental dew-point temperature is lower than 28˚C and the relative humidity is less than 80%.

This unit is tested under ISO installation conditions to make sure that there are no defects. However, if it is operated

under conditions of high humidity that exceed the conditions above, there is danger of condensate falling from the

unit. If there is a possibility that the unit will be used under such conditions, dress 10~20 mm of insulation on the

entire unit body, the piping and drain pipe.

3) Check if the selected place for installation is rigid enough to stand the weight of thew unit.

Otherwise, apply reinforcement using boards and beams before starting the installation work.

1100

1300

1720

Models

FDUMA202R

FDUMA252, 302R

FDUMA402 ~ 602R

A

600

600

600

B

Mark

Unit : mm

620

Inspection

space

B

100

A

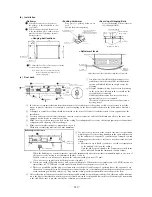

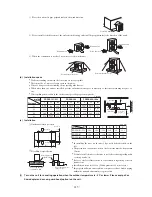

(ii) Suspension

Be sure to observe the finished length of the suspension bolts given below.

1) Fixing the suspension bolt (customer ordered parts M10)

Securely fix the suspension bolt as illustrated below or in another way.

786

986

1406

Models

FDUMA202R

FDUMA252, 302R

FDUMA402 ~ 602R

A

Mark

Unit : mm

472

A

Insert

Hole in anchor bolt

Hole-in plug

Suspension bolt M10

Concrete