-

206

-

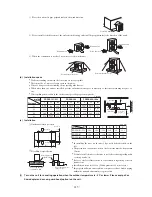

• There is a possibility that the supply air volume may exceed the allowable range of operation due to the capacity of

ventilation fan or strength of wind blowing against external air louver so that drainage from be heat exchanger may

fail to reach the drain pan leak outside (e.g. drip on to the with consequential water leakage in the room.)

Notice: Aspecific cover plate is available when changing the 4 spot to the 3 spot, or when changing the 3 spot to the 2

spot.

Note (1) Do not change from 2 spot to 1 spot.

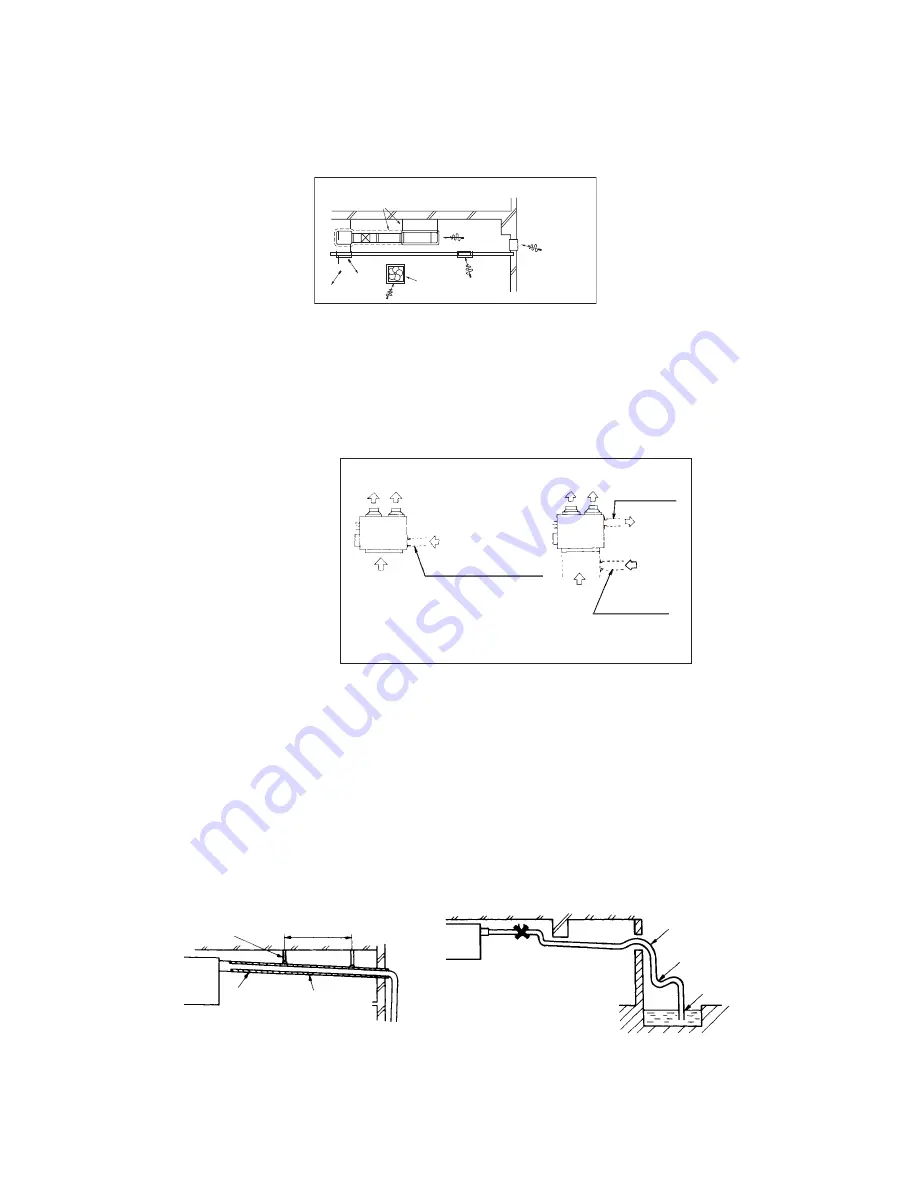

Bad example of duct work

For ventilation

Louver to

outdoor air

Return air duct: Use square duct.

Return air port with canvas duct

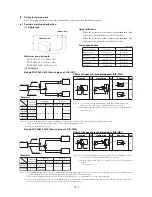

1) Connection of intake and exhaust ducts.

2) Duct connecting position.

< Fresh air intake >

a) Use side air intake port.

b) In case of simultaneous intake and exhaust, the side air intake port cannot be used, therefore, take air from the

midway air intake port along the intake duct.

< Exhaust >

Make sure to use suction as well.

c) Use a side exhaust port.

3) Duct connection

Use intake and exhaust duct fl ange of separately sold (for connection of ø125mm round duct) to connect ø125mm

round duct. The duct clamped by bands must be thermally insulated to prevent dew condensation.

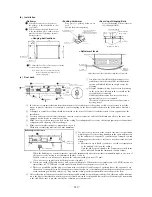

(iv) Drain

piping

1) Drain piping should always be in a downhill grade (1/50-1/100) and avoid riding across an elevation or making traps.

1.5 m ~ 2m

Suspension

bolts

Heat

insulation

A downhill grade

of 1/100 or more

Air vent

Avoid riding across an elevation

Keep free from traps

Do not pipe under water

•

Good piping

•

Improper piping

Looking from top of unit

Exhaust port

Side fresh air intake port

Intake duct

(square duct)

Fresh air intake

port midway

of return duct

Fig.2

Fig.1