-

209

-

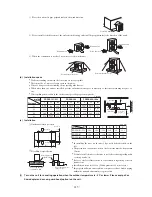

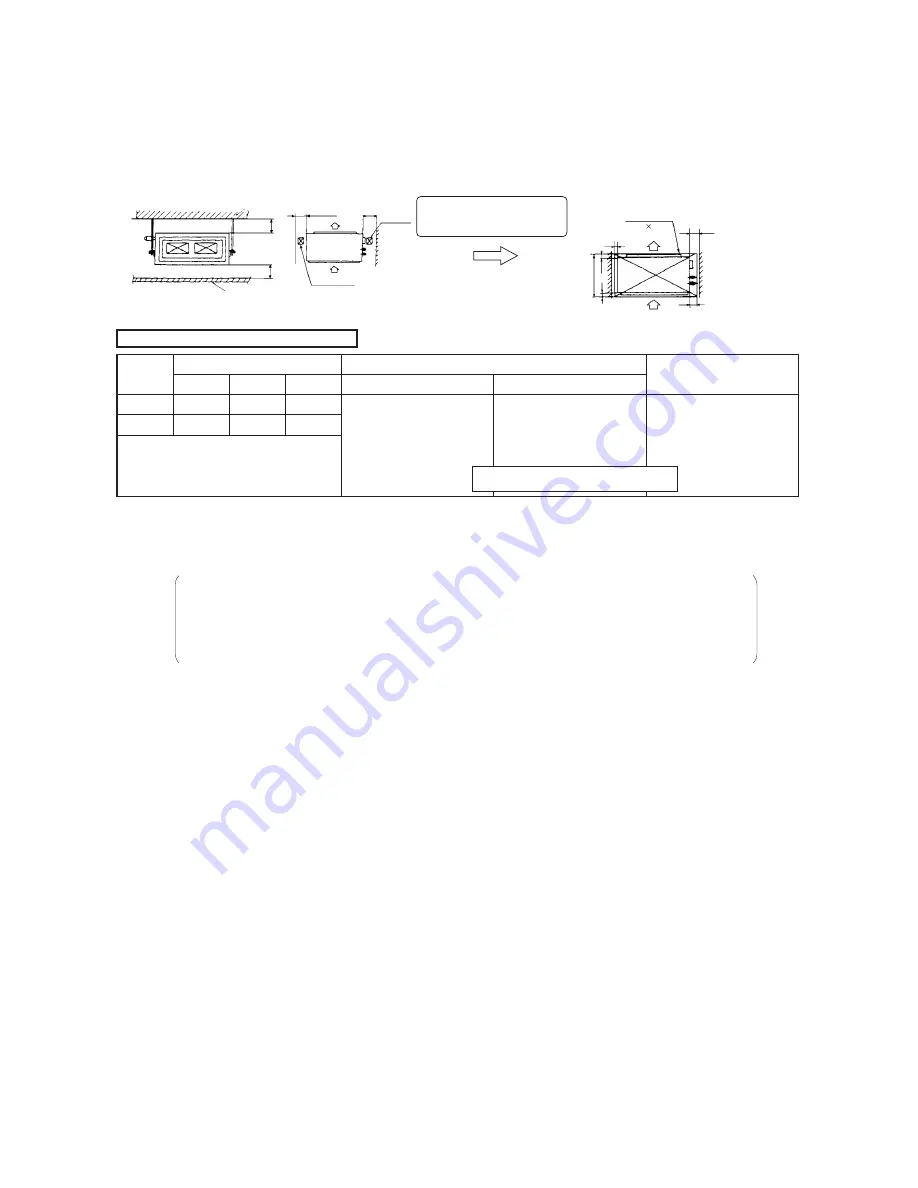

Air conditions, limitation of air volume

Air volume (m

3

/min)

Indoor unit suction air temperature

801 model

51

38

65

Rating

Lower limit

Upper limit

Cooling

Heating

Upper limit 26˚CWB

When outdoor temperature is 35˚C

Lower limit 16˚CWB

When outdoor temperature is 15˚C

Upper limit 27˚CDB

Outdoor temperature is below 20˚CWB

Lower limit 10˚CDB

Outdoor temperature is above 10˚CWB

Dew point temperature below 23˚C

Ambient temperature around

indoor unit

1001 model

68

51

87

For further details refer to the engineering data

which

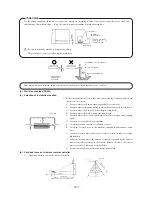

Front view

Top view

Ceiling

Slab

All Series

Min.

200

Min.

300

Min. 9 00

Min. 900 Inspection

hole

Inspection hole

(600

×

600)

Installation space

(600

×

600)

Intake

Blowout

Service

space

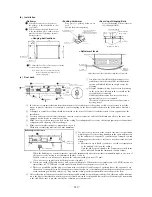

(6) High static pressure duct type (FDU)

(a) Selection of installation location

1)

Install the unit at a place as shown below and which meets the conditions as shown by the following table.

Plan view

All series

Intake

100

Min. 400

Piping space

Unit : mm

900

35

35

Front view shall be same

as shown at left.

60

Blowout

Inspection hole

(900 1730)

When the conditions as shown at

left cannot be met, following

alternative solution may be taken.

2)

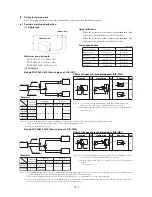

Places where perfect drainage can be prepared and sufficient drainage gradient is available.

3)

Places free from air disturbances to the air inlet and outlet of the indoor unit.

4)

Places with the environmental dew-point temperature is lower than 28°C and the relative humidity is less than 80%.

This unit is tested under ISO installation conditions to make sure that there are no defects. However, if it is operated

under conditions of high humidity that exceed the conditions above, there is danger of condensate falling from

the unit. If there is a possibility that the unit will be used under such conditions, dress 10~20 mm of insulation on

the entire unit body, the piping and drain pipe.

5)

Do not place where the unit is exposed to oil splashes or steam (e.g. kitchens and machine plants).

(Installation and use at such places will cause the performance drop, corrosion in the heat exchanger and damage in molded

synthetic resin parts.)

6) Do not place where corrosive gas (such as sulfurous acid gas) or infl ammable gas (thinner, gasoline, etc.) is generated or

remains.

Installation and use at such places will cause corrosion in the heat exchanger and damage in molded synthetic resin parts.

7)

Do not place adjacent to equipment generating electromagnetic waves or high-frequency waves such as in hospitals, Gener-

ated noise may cause malfunctioning of the controller.