-

211

-

4)

When constructing drain piping for several units, position the common pipe about 100 mm below the drain outlet of each unit

as shown in the sketch. Use VP-30 (11/4˝) or thicker pipe this purpose.

5)

Be sure to provide heat insulation to hard PVC pipes of indoor placement.

6)

Do not ever provide an air vent.

7)

Avoid postitioning the drain piping outlet at a place where generation of odor may be stimulated. Do not lead the drain piping

direct into a sewer from where sulfur gas may generate.

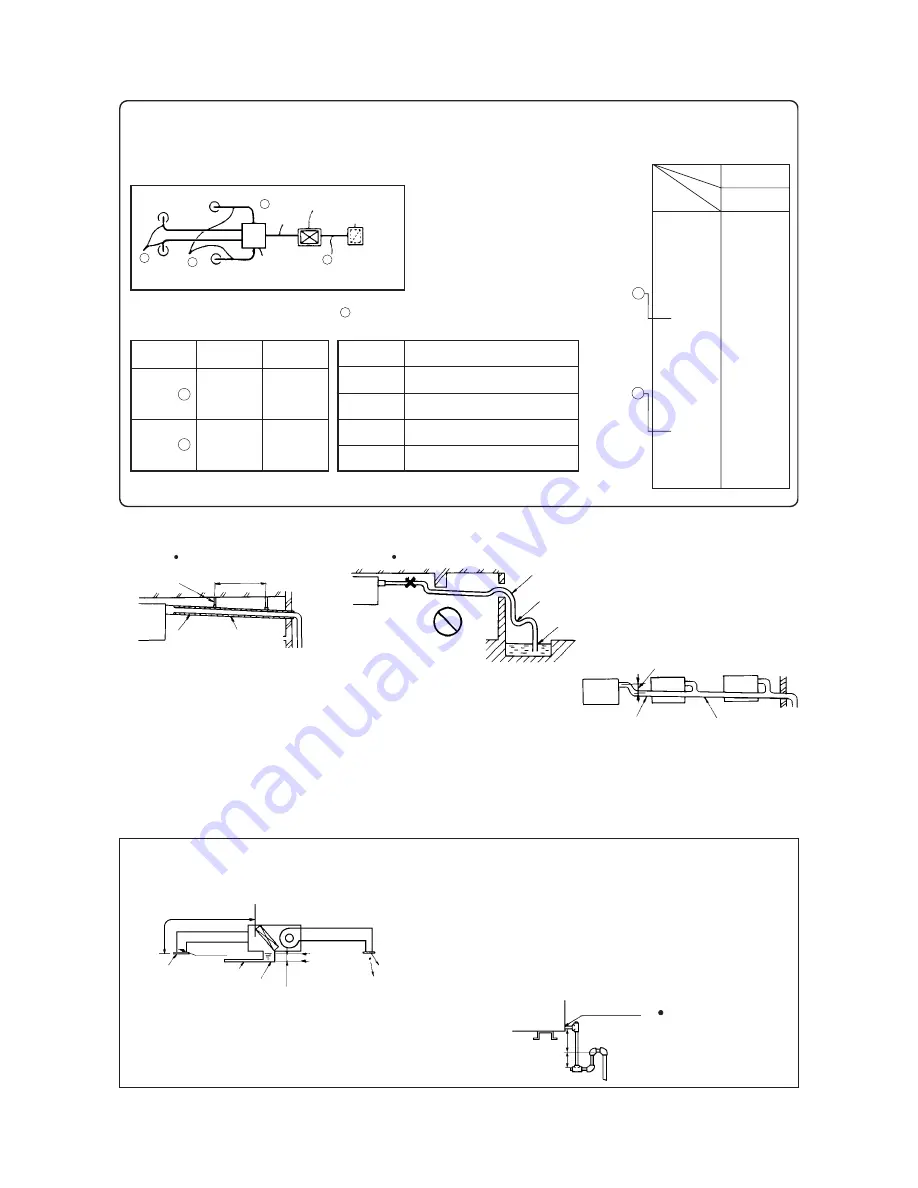

If the duct is connected and then the blower is operated,

inside air pressure will become negative compared with

the atmospheric pressure.

Duct

Duct

Air filter

Air outlet grille

In running

In stopping

Pressure head loss,

suction side 10 mmAq

Drain pipe

Drain pan

10 mm

Suction grill

Example: If the pressure loss at the suction side, such as the suc-

tion grill, air filter and duct, is 100 Pa, the level of drain

water will rise approx. 10 mm higher than the state of

operation stop.

<Provision of trap>

Since the drain outlet is disposed at a position

that makes the pressure negative, it is necessary

to provide a trap (during the piping work) in order

to prevent water leakage due to rising of water

level in the drain pan.

Trap must be so constructed to facilitate cleaning.

It should be better to employ a “T” joint as shown

below. In addition, the height of trap should be

as specified below. The trap should be provided

close to the unit.

Unit

Drain connection

H

2

H

1

Provide a trap on way

of the drain pipe as

shown at left.

H

1

=100 mm or static pre-

ssure of blower

H

2

=1/2 H

1

or 50 ~ 100 mm

(d) Drain

Piping

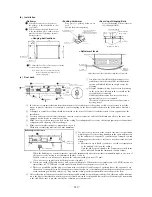

1)

Drain piping should always be in a downhill grade (1/50~1/100) and avoid riding across an elevation or making traps.

Avoid riding across an elevation

Keep free from traps

Do not pipe under water

Air vent

Improper piping

Suspension

bolts

1.5m ~ 2m

Heat

insulation

A downhill grade

of 1/100 or more

Good piping

2)

When connecting the drain pipe to unit, pay sufficient attention not to apply

excess force to the piping on the unit side. Also, fix the piping at a point as

close as possible to the unit.

3)

For drain pipe, use hard PVC general purpose pipe VP-25(I.D.1˝) which can

be purchased locally.

A downhill grade of

1/100 or more

Secure the elevation as high as possible

(approx. 100 mm)

V.P.30

1020 m

3

/h

B

1020 m

3

/h

B

4080 m

3

/h

A

4080 m

3

/h

Supply

(blowout)

chamber

Air conditioner

indoor unit

With air filter

A

<Table of simplified selection

of duct dimensions>

Air

volume

Duct

(mm

×

mm)

4080m

3

/h

(68m

3

min)

250

×

830

1020m

3

/h

(17m

3

min)

250

×

270

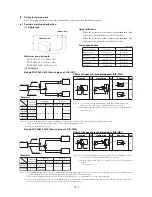

Calculation of duct resistance

(Use following simplified calculations.)

Linear pipe

section

Calculate based on 1 Pa

per 1 m in length 1 Pa/m.

Curved pipe

section

Take a curved section as equivalent to 3

~4 m in straight line.

Blowout

section

Calculate based on 25 Pa.

Chamber

Calculate by taking 1 pc. as 50Pa.

Suction grill

(with filter)

Calculate by taking 1 pc. as 40Pa.

Square duct

Dimensions

Duct form

Item

Air

volume

m

3

/h(m

3

/min)

100

200

300

400

500

600(10)

800

1,000

1,200(20)

1,400

1,600

1,800(30)

2,000

2,400

3,000(50)

3,500

4,000

4,500

5,000

5,500

6,000(100)

(mm

×

mm)

250

×

60

250

×

90

250

×

120

250

×

140

250

×

170

250

×

190

250

×

230

250

×

270

250

×

310

250

×

350

250

×

390

250

×

430

250

×

470

250

×

560

250

×

650

250

×

740

250

×

830

250

×

920

250

×

1000

250

×

1090

250

×

1180

Section A

Section B

Section B

Section A

<Simplifi ed method for determination of duct dimensions>

In the following method, it is assumed that the friction resistance per unit length of duct is

1 Pa/m (0.1 mm Aq/m) and a side of duct is 250 mm.

Air volume rating is assumed to be FDUA1001R.