-

219

-

Do not hold the valve cap area with a spanner.

Please use a torque wrench. If a torque wrench is not

available, fasten the flare nut manually first and then

tighten it further, using the left table as a guide.

(c) Points for attention in installing refrigerant piping

1) Use pipes made of the following material

Material: Phosphorus deoxidized copper seamless pipes (C1220T, JIS

H3300)

2) Please dress the refrigerant piping (both gas and liquid pipes) with a heat

insulating material for prevention of dew condensation. Improper heat

insulation incapable of preventing dew condensation can cause the leaking

or dripping of water and a resultant soaking of household effects.

3) Use only a good heat insulating material (120°C or higher) for heat insula-

tion. A poor heat insulating material offers only poor heat insulation and

can cause cable deterioration.

a) The gas pipes can cause dew condensation during a cooling opera-

tion, which may become drain water causing a water-leak accident,

or a risk of burns during a heating operation, if touched accidentally,

with its surface reaching a high temperature because of discharged

gas fl owing inside. So, do not fail to dress it with a heat insulating

material to prevent such mishap.

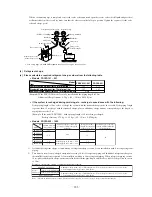

b) Dress the fl are joints of the indoor units with a heat insulating material

(pipe covers) (for both gas and liquid pipes).

c) Dress both gas and liquid pipes with a heat insulating material. In

doing so, leave no gaps between the pipe and the heat insulating

material and wrap them, together with the connecting cable, with a

dressing tape.

d) If the unit is used in a place where dew point in the ambient atmo-

sphere is 28ºC or higher, and the relative humidity is 80% or higher,

dress 20 mm or more of insulation.

4) When you need to bend a pipe, bend it to the largest possible radius

(R100-R150) permitted. Do not bend a pipe repeatedly in an effort to

shape it appropriately.

5) In laying pipes, take care to avoid debris, chips or water

from entering the piping system.

6) A unit and a refrigerant pipe are to be fl are connected.

Flare a pipe after you have attached a fl are nut to the pipe.

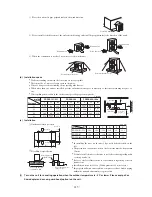

The dimensions of fl aring for R410A are different from

those for the conventional R407C refrigerant. Although

we recommend the use of fl are tools developed specifi cally

for R410A, conventional fl are tools can also be used, if the

measurement of protrusion B is adjusted with a protrusion

control copper pipe gauge.

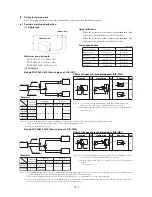

7) Tighten

a

fl are joint securely with double spanners. Observe

the following tightening torque values for fl are nuts:

8) A branching pipe set (option part supplied separately) and

refrigerant piping should be connected by brazing.

9) In brazing pipes, keep nitrogen gas fl owing inside the pipes

so that an oxide fi lm may not form on the inner surfaces of

the pipes.

Exterior tape

Gas piping

Liquid piping

Wires for connecting

indoor and outdoor

units

Insulation

A

B

9.1

13.2

16.6

19.7

ø6.35

ø9.52

ø12.7

ø15.88

0

-0.4

A

Copper

pipe outer

diameter

Flared pipe end: A (mm)

0~0.5

φ

6.35

φ

9.52

φ

12.7

φ

15.88

Copper

pipe outer

diameter

Copper pipe protrusion for flaring: B (mm)

0.7~1.3

With an R410A tool

In the case of a rigid (clutch) type

With a conventional tool

Operation valve

size (mm)

φ

6.35 (1/4")

φ

9.52 (3/8")

φ

12.7 (1/2")

φ

15.88 (5/8")

Tightening

torque (N·m)

14~18

34~42

49~61

68~82

Tightening

angle (˚ )

45~60

30~45

30~45

15~20

Recommended length

of a tool handle (mm)

150

200

250

300

10) Tighten a fl are joint securely with a double spanner.

a) Do not apply force beyond proper fastening torque in tightening the fl are nut.

b) Fix both liquid and gas service valves at the valve main bodies as illustrated on the lower, and then fasten them,

applying appropriate fastening torque.