-

222

-

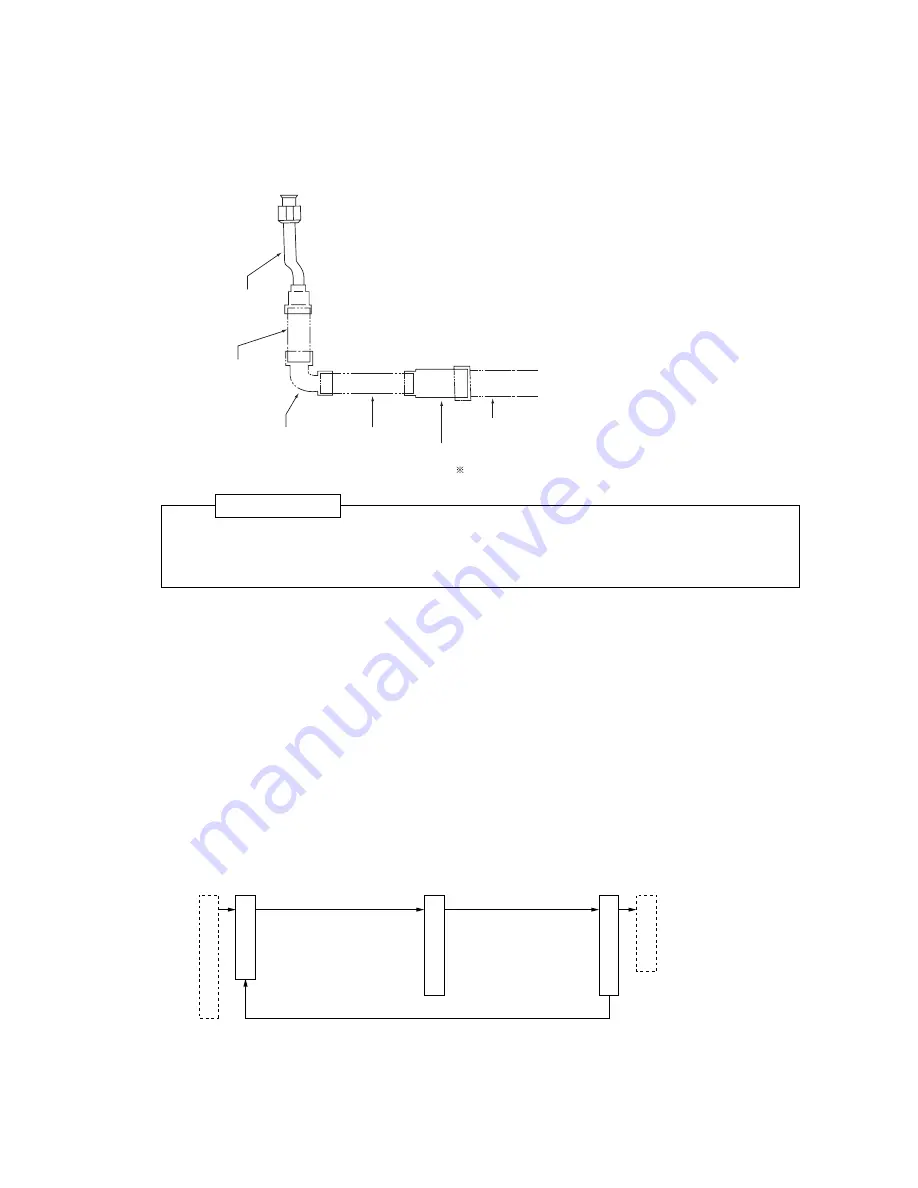

Straight pipe

φ

22.2 (OD)

to be procured locally

Branching pipe set

(DIS-WB1, DIS-TB1)

Accessory pipe A

Elbow to be

procured locally

Accessory pipe B

Field piping

φ

22.2 (OD)

In case of V-multi

Branching pipe set can be used by using the accessory pipe B. When

φ

22.22(OD) size of the indoor unit gas pipe is used,

the accessory pipe B is unnecessory.

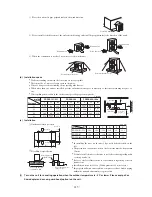

After connection of the connecting pipe assembly to the operation valve on the gas side, braze the connecting pipe assembly and the

field pipe.

Be sure to braze while supplying nitrogen gas.

If no nitrogen gas is supplied, a large amount of impurity (oxidized film) will be generated, which may

clog the capillary tube and the expansion valve, resulting in fatal malfunction.

About brazing

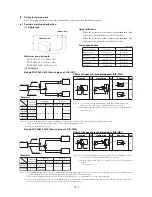

4)

Airtightness test completed

Vacuuming begins

Vacuuming completed

Vacuum gauge check

Fill refrigerant

When the vacuum gauge's needle pointer creeps up, there is moisture left in the system

or a leak. Pull air again after you have checked the system for a leak and rectified it. Use

a reverse flow stop adapter to prevent the vacuum pump's lubricant oil from flowing into

the refrigerant system.

Please run the vacuum pump for at

least one hour after the vacuum gauge

shows -101kPa or lower. (-755mmHg

or lower)

No increase in the reading of the

vacuum gauge's needle pointer.

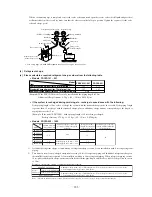

(3) Air tightness test and air purge

•

Always use a vacuum pump to purge air trapped within an indoor and the refrigerant piping

.

(a)

Air tightness test

1)

When all the fl are nuts on both indoor and outdoor unit sides are fastened. Conduct an air-tightness test from the service

valves (on both liquid and gas sides) closed tightly to check whether the system has no leaks.

2)

Use nitrogen gas in the air-tightness test. Do not use gas other than nitrogen gas under any circumstances.

Conduct the air-tightness test by applying 4.15MPa of pressure.

3)

Do not apply the specifi ed pressure at once, but increase pressure gradually.

a)

Raise the pressure to 0.5 MPa, and then stop. Leave it for fi ve minutes to see if the pressure drops.

b)

Then raise the pressure to 1.5 MPa, and stop. Leave it for fi ve more minutes to see if the pressure drops.

c)

Then raise the pressure to the specifi ed level (4.15 MPa), and record the ambient temperature and the pressure.

d)

If the pressure does not drop after the units is left for approximately one day, the airtighteness is acceptable.

When the ambient temperature changes 1˚C, the pressure also changes approximately 0.01 MPa. The pressure. if

changed, should be compensated for.

(b) Air

purge