-

236

-

Indoor unit

Outdoor unit

Gas line

Liquid line

Charge hose

Charge hose

Gauge manifoid

Charge valve

Vacuum adapter

Vacuum

pump

Handle Lo

Handle Hi

Charge port

Refrigerant

cylinder

A

1.6 MAINTENANCE

DATA

1.6.1 Servicing

(1) Evacuation

The evacuation is a procedure to purge impurities, such as noncondensable gas, air, moisture from the refrigerant equipment by

using a vacuum pump. Since the refrigerant R410A is very insoluble in water, even a small amount of moisture left in the refriger-

ant equipment will freeze, causing what is called ice clogging.

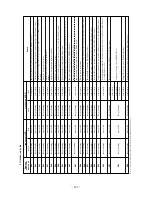

Evacuation

procedure

Make sure that the both service valves of gas and liquid line are fully opened.

(a) Check to ensure that there is no internal

pressure in the unit. If there is an internal

pressure, it should be relieved through the

service port.

(b) Connect the charging hose of the gauge mani-

fold to the service port of the gas piping.

Close high pressure valve

2

of gauge mani-

fold.

(c) Connect the charging hose

to a vacuum

pump.

Repeat evacuation in the following se-

quence.

Notes (1) Do not use the refrigerant pressure to expel air.

Notes

(2) Do not use the compressor for evacuation.

Notes

(3) Do not operate the compressor in a vacuum condition.

Vacuuming begins

Vacuuming completed

Vacuum gauge check

When the vacuum gauge's needle pointer creeps up,

there is moisture left in the system or a leak. Pull air

again after you have checked the system for a leak and

rectified it. Use a reverse flow stop adapter to prevent

the vacuum pump's lubricant oil from flowing into the

refrigerant system.

Please run the

vacuum pump for at

least one hour after

the vacuum gauge

shows -101kPa or

lower. (-755mmHg or

lower)

No increase in the

reading of the

vacuum gauge's

needle pointer.