-

265

-

L

N

E

TB

TB

Red

White

Y/NG

LED1

Red

T1

T5

Red

White

Black

Orange

Y ello

w

UV

W

T6

T7

T8

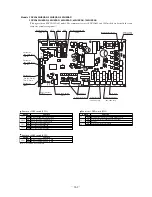

CM

F2 (250V 20A)

CnTR

Control PCB

Power transistor module

CNI3

T2

T4

6

DC280V

F3 (250V 1A)

F5

(20A

)

4

3

2

1

CNI2

FM

0

T21

T22

Sub PCB

(Noise filter)

T24

T25

T26

T30

T27

T28

CNI1

Or

ange

Gr

a

y

T

o indoor unit

Bro

wn

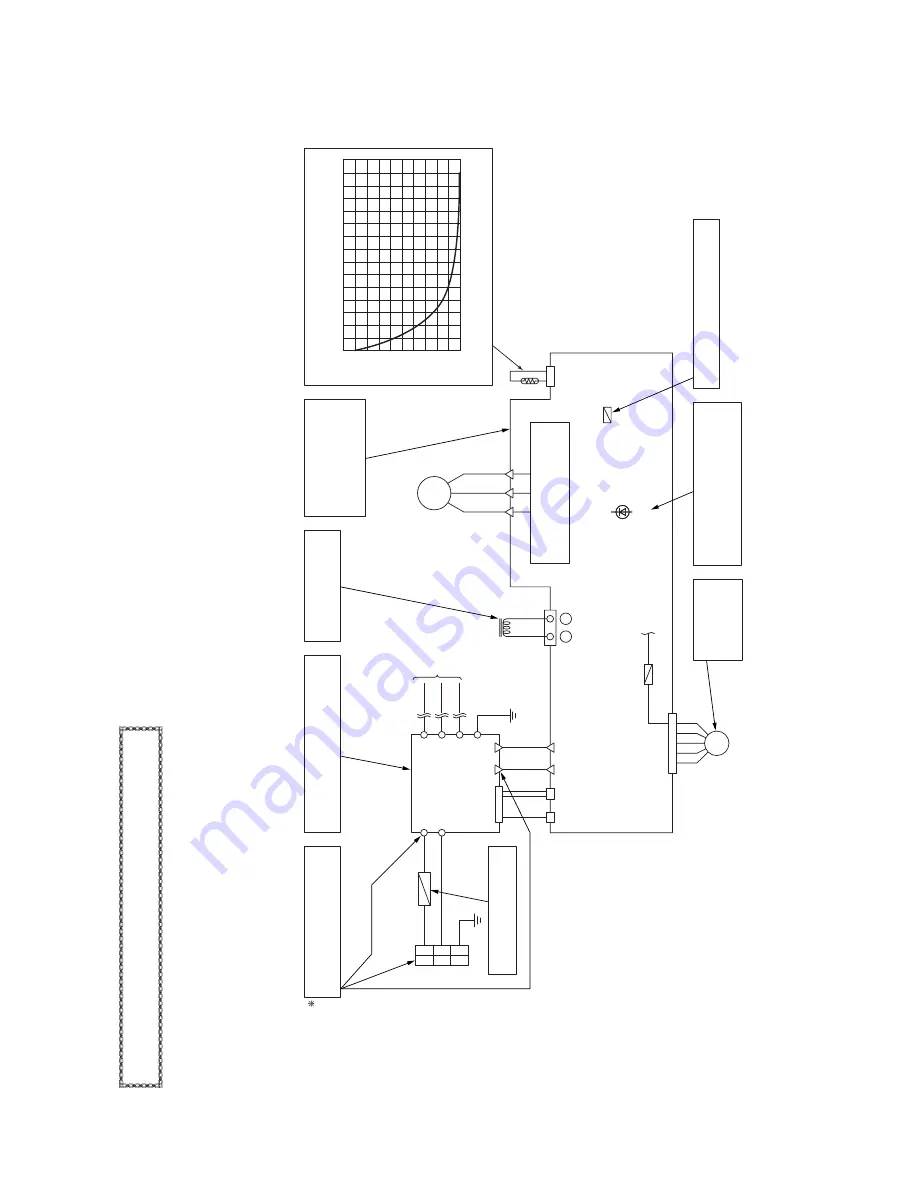

Power transistor thermistor temperature and

resistance characteristics check

0

20

40

60

80

100

120

140

160

180

200

T

emperature (˚C)

Thermistor resistance (k

Ω

)

0

20

40

60

80

100

120

140

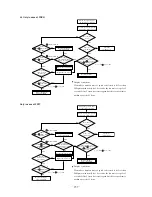

Power transistor module

check: Is there a short cir-

cuit, open circuit or dam-

age? (See

284

page for the

check procedure.)

DC Reactor continuity

Check: 50 m or higher,

less than 100 m

Ω

.

Fuse check: There should be continuity.

If faulty, replace the control PCB.

Noise filter check:

There should be continuity.

There should be no shorts between phases.

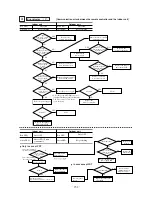

LED1 (Red) check

Light continuously :

Keeps flashing :

1~3 time flash :

Normal

EEV

(Refer to page

239

)

Power supply check

Measure the power supply at L.N.

(It is normal if it is AC 220/240V.)

Fuse Check: There should be

continuity.

When the outdoor

unit fan motor is

anomalous:

(Refer to page

280

)

Models FDCV

A151~251HENR

Outdoor unit check points

Check items with the *mark when the po

wer is ON.

Outdoor Unit contr

oller failure dia

gnosis cir

cuit dia

gram

Summary of Contents for FDCVA1002HESAR

Page 107: ... 106 60 17 150 b Wireless remote controller Unit mm ...

Page 119: ... 118 Model FDCVA1002HESAR Polar white ...

Page 133: ......