-

-

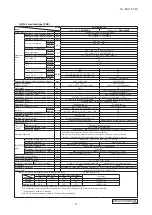

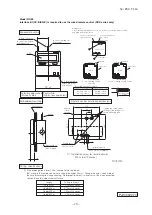

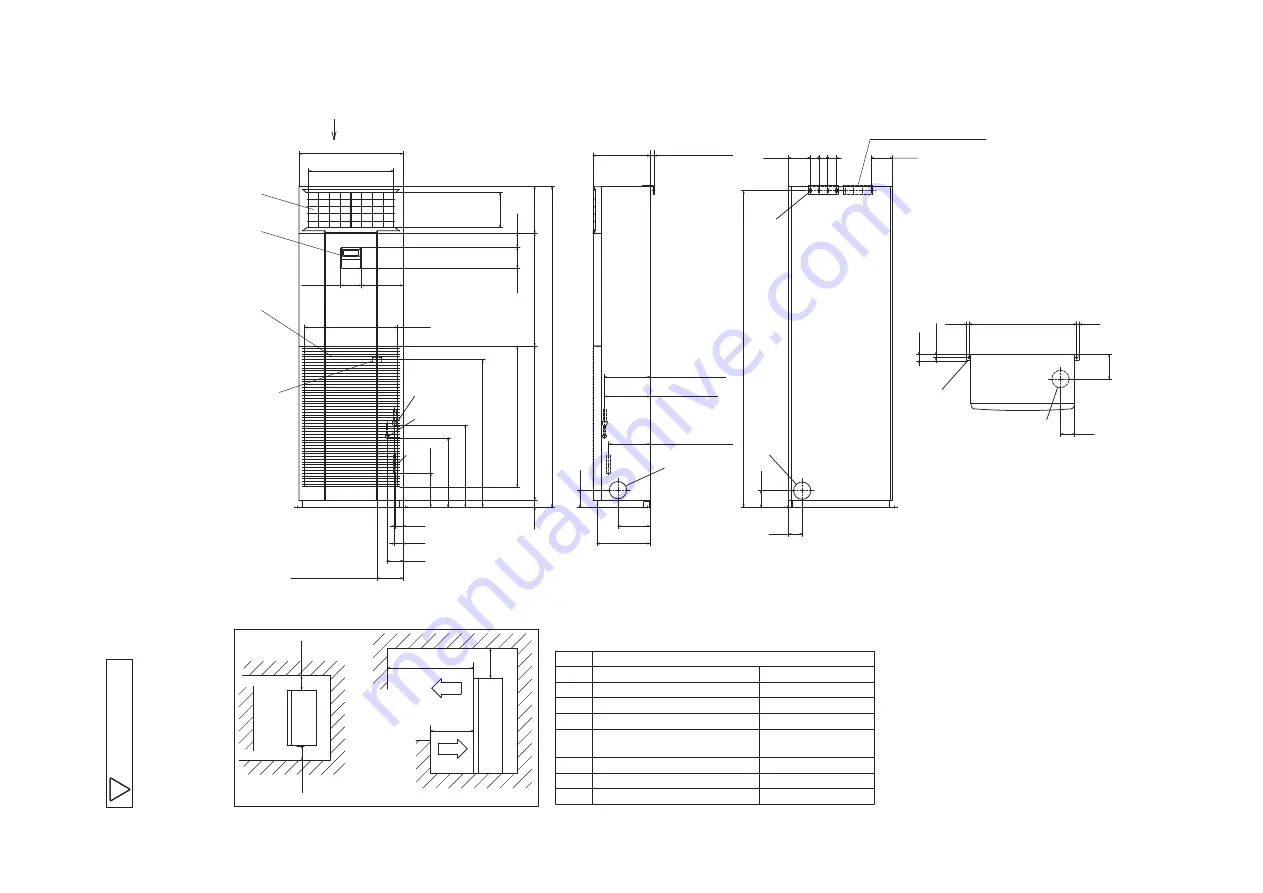

'16 • PAC-T-240

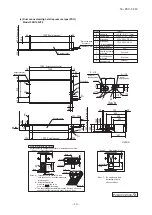

Space for installation and service

A

E

C

B

A

D

F

H

G

A

or

m

or

e

or

m

or

e

or

m

or

e

or more

or more

490

19

7.

5

80

600

240

120

18

50

65

0

27

0

537

78

95

18

27

50

50

50

185

306

48

93

40

0.

5

47

4

45

19

6

89

0

40

12

0

85

2

150

98

329

600

1000

10

0

50

Air return

Air supply

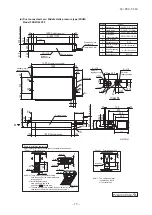

125

(

Range that

262

(

Gas

)

264

(

Liquid)

238.5

(

Drain

)

125

H can be installed left

Terminal block

(

Power source

)

Air supply

81

2.

5

50

φ

100

(

Knock out

)

Hole on wall for rear piping

4-7

×

25

(

Slot

)

Fresh air intake

(

Both left and right

)

Hole on wall for side piping

/

M8

(

2 places

)

φ

100

(

Knock out

)

φ

100

(

Resin cap having

)

VP20

(

I.D.20,O.D.26

)

Fall prevention metal fittings

Metal fittings to fix to floor face

Hole on wall for bottom piping

Drain piping

Liquid piping

Gas piping

H

G

F

E

D

C

B

A

Content

Symbol

φ

9.52

(

3

/

8"

)(

Flare

)

φ

15.88

(

5

/

8"

)(

Flare

)

14

3

82

15

622.5

15

17

.5

35

25

-

50

Unit:mm

(

Center of

terminal block

)

(

Ce

nt

er

of

te

rm

in

al

bl

oc

k

)

can be adjusted

)

Remote

control

Air return

grille

Note

(

1

)

The model name label is attached on the

left lower side panel inside the air return grille.

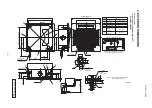

(e) Floor standing type (FDF)

Model FDF100VD2

A

P

G

A

0

0

0

Z

8

0

1