-

65

-

'16 • PAC-T-240

⑦

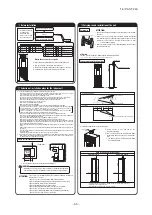

Drain pipe (continued)

3. Make sure to make descending slope of greater than 1/100 and do not make up-down bend

and/or trap in the midway.

●

Pay attention not to give stress on the pipe on the indoor unit side, and support and fix the

pipe as close place to the unit as possible when connecting the drain pipe.

●

Do not set up air vent.

●

When sharing a drain pipe for more

than one unit, lay the main pipe 100mm

below the drain outlet of the unit. In

addition, select VP-30 or bigger size for

main drain pipe.

4. Insulate the drain pipe.

●

Be sure to insulate the drain socket and rigid PVC pipe installed indoors otherwise it may

cause dew condensation and water leakage.

※

After drainage test implementation, cover the drain socket part with pipe cover (small

size), then use the pipe cover (big size) to cover the pipe cover (small size), clamps and

part of the drain hose, and fix and wrap it with tapes to wrap and make joint part gapless.

Drain up

●

The position for drain pipe outlet can be raised up to 600mm above the ceiling. Use elbows

for installation to avoid obstacles inside ceiling. If the horizontal drain pipe is too long before

vertical pipe, the backflow of water will increase when the unit is stopped, and it may cause

overflow of water from the drain pan on the indoor unit. In order to avoid overflow, keep the

horizontal pipe length and offset of the pipe within the limit shown in the figure below.

Otherwise, the construction point makes it same as drain pipe construction.

Drain test

1. Conduct a drain test after completion of the electrical work.

2. During the trail, make sure that drain flows properly through the piping and that no water

leaks from connections.

3. In case of a new building, conduct the test before it is furnished with the ceiling.

4. Be sure to conduct this test even when the unit is installed in the heating season.

Procedures

1. Supply about 1000 cc of water to the unit through the air outlet by using a feed water pump.

2. Check the drain while cooling operation.

Outline of bottom drain piping work

●

If the bottom drain piping can be done with a

descending gradient (1/50-1/100), it is possible to

connect the pipes as shown in the drawing below.

Uncoupling the drain motor connector

●

Uncouple the connector CNR for the drain motor as

illustrated in the drawing on the right.

Note: If the unit is run with the connector coupled,

drain water will be discharged from the upper

drain pipe joint, causing a water leak.

P.C. board

Insert water supply hose

for 20mm – 30mm to

supply water.

(Insert hose facing

toward bottom.)

Attached drain hose clamp

Drain

piping

Main

unit

Drain situation can be checked with transparent socket.

If the electrical work has not been completed, connect a convex

joint in the drain pipe connection to provide a water inlet.

Then, check if water leaks from the piping system and that

drain flows through the drain pipe normally.

Pour water into a convex joint

Remove grommet

Make sure to Install

it back after test.

Connecting port of top drain pipe

Insulating material

Transparent soft tube

(Prepare on site)

Rubber stopper (to be removed)

Connecting port of bottom drain pipes

(Outside diameter:20mm)

Standard hard polyvinyl

chloride pipes

(

)

600 max

295-325

100 or less

⑥

Refrigerant pipe (continued)

4. Refrigerant is charged in the outdoor unit.

As for the additional refrigerant charge for the indoor unit and piping, refer to the installation

manual attached to the outdoor unit.

Caution:

Refrigerating machine oil should not be applied to the threads of union or external surface of flare. It

is because, even if the same tightening torque is applied, the oil is likely to decrease the slide friction

force on the threads and increase, in turn, the axial component force so that it could crack the flare

by the stress corrosion.

Refrigerating machine oil may be applied to the internal surface of flare only.

Descending slope greater than 1/100

As wide as possible

(about100mm)

Supporting metal

Descending slope greater than 1/100

* Please confirm that the pipe doesn’t bend.

Air vent

No bump

No trap

Not touching the water

Trapped air will

generate noises.

VP-30 or bigger

1m~2m*

PJG012D008C

D

<

The case of using thicness of insulation is 10mm

>

<

The case of using reinfoced insulation

>

Pipe cover (Accessory)

Unit

Unit

Band

(Accessory)

Band

(Prepare on site)

Insulation (Prepare on site)

Pipe cover (Prepare on site)

Band

(Accessory)

The thckness of insulation is 10mm

⑦

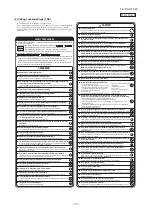

Drain pipe

Caution

●

Install the drain pipe according to the installation manual in order to drain properly.

Imperfection in draining may cause flood indoors and wetting the household goods, etc.

●

Do not put the drain pipe directly into the ditch where toxic gas such as sulfur, the other harmful

and inflammable gas is generated. Toxic gas would flow into the room and it would cause

serious damage to user’s health and safety (some poisoning or deficiency of oxygen).

In addition, it may cause corrosion of heat exchanger and bad smell.

●

Connect the pipe securely to avoid water leakage from the joint.

●

Insulate the pipe properly to avoid condensation drop.

●

Check if the water can flow out properly from both the drain outlet on the indoor unit and the end

of the drain pipe after installation.

●

Make sure to make descending slope of greater than 1/100 and do not make up-down bend

and/or trap in the midway. In addition, do not put air vent on the drain pipe. Check if water is

drained out properly from the pipe during commissioning. Also, keep sufficient space for

inspection and maintenance.

Work procedure

1. Make sure to insert the drain hose (the end mode of soft PVC) to the end of the step part

of drain socket.

Attach the hose clamp to the drain hose around 10mm from the end, and fasten the

screw within 5mm left to the nut.

●

Do not apply adhesives on this end.

●

Do not use acetone-based adhesives to connect to the drain socket.

2. Prepare a joint for connecting VP-25 pipe, adhere and connect the joint to the drain hose (the

end made of rigid PVC), and adhere and connect VP-25 pipe (prepare on site).

※

As for drain pipe, apply VP-25 made of rigid PVC which is on the market.

●

Make sure that the adhesive will not get into the supplied drain hose.

It may cause the flexible part broken after the adhesive is dried up and gets rigid.

●

The flexible drain hose is intended to absorb a small difference at installation of the unit or

drain pipes. Intentional bending, expanding may cause the flexible hose broken and water

leakage.

●

As for drain pipe, apply VP25 (OD32).

If apply PVC25 (OD25), connect the expanded connector to the drain hose, with adhesive.

(Multi unit only)

Drain socket

Pipe cover (big) (For insulation)

(Accessory)

VP25 joint (Prepare on site)

VP25

(Prepare on site)

Pipe cover (small)

(For insulation) (Accessory)

Unit

Clamp (Accessory)

Pipe cover (small)

(For insulation)

(Prepare on site)

Drain socket

Metal plate

10mm

Hose clamp

Fasten the screw within

5 mm left to the nut.

Drain hose

Drain socket

Drain hose

Stage difflernce part

Drain hose

(Accessory)

Adhesion

295

ー

325mm

PVC25 (Prepare on site)

Elbow (Accessory)

(Multi only)

Drain hose

Indoor side

Insulation material

Insulation material

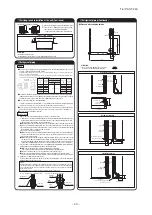

⑤

Duct Work (continued)

⑤

Duct Work

Connecting the air intake/vent ducts

①

Fresh Air Intake

[for air intake duct only]

○

Use the side fresh air intake hole, or supply

through a part of the suction duct.

[for simultaneous air intake/vent]

○

Intake air through the suction duct.

(the side cannot be used)

②

Air Vent

○

Use the side air vent hole.

(always use together with the air intake)

○

Insulate the duct to protect it from dew condensation.

①

A corrugated board (for preventing sputtering) is attached to the main body of the air-conditioner

(on the outlet port). Do not remove it until connecting the duct.

●

An air filter can be provided on the main body of the air-conditioner (on the inlet port). Remove

it when connecting the duct on the inlet port.

②

Blowout duct

●

Use rectangular duct to connect with unit.

Duct size for each unit is as shown below.

●

Duct should be at their minimum length.

●

We recommend to use sound and heat insulated duct to prevent it from condensation.

●

Connect duct to unit before ceiling attachment.

③

Inlet port

●

When shipped the inlet port lies on the back.

●

When connecting the duct to the inlet port, remove the air filter if it is fitted to the inlet port.

●

When placing the inlet port to carry out suction from the bottom side, use the following

procedure to replace the suction duct joint and the bottom plate.

●

Remove the screws which fasten the

●

Replace the removed bottom plate

bottom plate and the duct joint on the

and duct joint.

inlet port side of the unit.

●

Fit the duct join with a screw; fit the bottom plate.

●

Make sure to insulate the duct to prevent dewing on it.

④

Install the specific blowout duct in a location where the air will

circulate to the entire room.

●

Conduct the installation of the specific blowout hole and the

connection of the duct before attaching them to the ceiling.

●

Insulate the area where the duct is secured by a band for dew

condensation prevention.

⑤

Make sure provide an inspection hole on the ceiling. It is indispensable to service electric

equipment, motor, functional components and cleaning of heat exchanger.

①

If a duct is not provided at the suction side but it is substituted with the space over the ceiling,

humidity in the space will increase by the influence of capacity of ventilation fan, strength of

wind blowing against the out door air louver, weather (rainy day) and others.

a)Moisture in air is likely to condense over the external plates of the unit and to drip on the

ceiling. Unit should be operated under the conditions as listed in the above table and within

the limitation of wind volume. When the building is a concrete structure, especially immedi-

ately after the construction, humidity tends to rise even if the space over the ceiling is not

substituted in place of a duct. In such occasion, it is necessary to insulate the entire unit with

glass wool (25mm). (Use a wire net or equivalent to hold the glass wool in place.)

b)It may run out the allowable limit of unit operation (Example: When outdoor air temperature

is 35°C DB, suction air temperature is 27°C WB) and it could result in such troubles as

compressor overload, etc..

c)There is a possibility that the blow air volume may exceed the allowable range of operation

due to the capacity of ventilation fan or strength of wind blowing against external air louver

so that drainage from be heat exchanger may fall to reach the drain pan but leak outside

(Example: drip on to the ceiling) with consequential water leakage in the room.

②

If vibration damping is not conducted between the unit and the duct, and between the unit and

the slab, vibration will be transmitted to the duct and vibration noise may occur. Also, vibration

may be transmitted from the unit to the slab. Vibration damping must be performed.

Secure with a band, etc.

Blowout

duct

Air-conditioner main unit

Ceiling suriace

Suction grille

(Locality)

Suction hole

(marketed item)

(with air filter)

Inspection hole

Suction duct

(marketed item)

Blow outlet

Blowout duct

(optional or marketed item)

Bad example of duct work

Bad example of duct work

For ventilation

Louver to

outdoor air

(Pipe side)

(Pipe side)

Side fresh air intake hole

Air vent hole

Fresh air intake through the

suction duct

Fresh air intake through the

suction duct

(Pipe side)

Air vent hole

Fresh air intake through the

suction duct

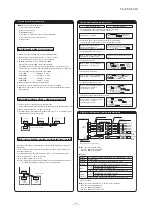

⑥

Refrigerant pipe

Single type

Multi type

A

B

40-50

22-56

682

172

60-71

71-90

882

172

100-140

112-140

1202

172

A

B

UNIT: mm

●

Be sure to use new pipes for the refrigerant pipes. Use the flare nut attached to the product

or a nut compatible with JIS B 8607, Class 2.

Regarding whether existing pipes can be reused or not, and the washing method, refer to the instruction manual of the

outdoor unit, catalogue or technical data.

1) In case of reuse: Do not use old flare nut, but use the one attached to the unit or compatible with JIS B 8607, Class 2.

2) In case of reuse: Flare the end of pipe replaced partially for R410A.

●

Use phosphorus deoxidized copper alloy seamless pipe (C1220T specified in JIS H3300) for refrigeration pipe installation.

In addition, make sure there is no damage both inside and outside of the pipe, and no harmful

substances such as sulfur, oxide, dust or a contaminant stuck on the pipes.

●

Do not use any refrigerant other than R410A.

Using other refrigerant except R410A (R22 etc.) may degrade inside refrigeration oil. And air getting into

refrigeration circuit may cause over-pressure and resultant it may result in bursting, etc.

●

Store the copper pipes indoors and seal the both end of them until they are brazed in order to avoid any dust, dirt or

water getting into pipe. Otherwise it will cause degradation of refrigeration oil and compressor breakdown, etc.

●

Use special tools for R410A refrigerant.

Piping work

When conducting piping work, make sure to allow the pipes

to be aligned in a straight line for at least 250 mm, as shown

in the left illustration. (This is necessary for the drain pump

to function)

Work procedure

1. Remove the flare nut and blind flanges on the pipe of the indoor unit.

※

Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving torque to the

nut with another spanner in order to avoid unexpected stress to the copper pipe, and then remove them.

(Gas may come out at this time, but it is not abnormal.)

●

Pay attention whether the flare nut pops out. (as the indoor unit is sometimes pressured.)

2. Make a flare on liquid pipe and gas pipe, and connect the refrigeration pipes on the indoor unit.

※

Bend radius of pipe must be 4D or larger. Once a pipe is bent, do not readjust the bending.

Do not twist a pipe or collapse to 2/3D or smaller.

※

Do a flare connection as follows:

●

Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving

torque to the nut with another spanner in order to avoid unexpected stress to the copper

pipe, and then remove them.

●

When fastening the flare nut, align the refrigeration pipe with the center of flare nut, screw

the nut for 3-4 times by hand and then tighten it by spanner with the specified torque

mentioned in the table above. Make sure to hold the pipe on the indoor unit securely by a

spanner when tightening the nut in order to avoid unexpected stress on the copper pipe.

3. Cover the flare connection part of the indoor unit with attached insulation material after a gas

leakage inspection, and tighten both ends with attached straps.

●

Make sure to insulate both gas pipes and liquid pipes completely.

※

Incomplete insulation may cause dew condensation or water dropping.

●

Use heat-resistant (120 °C or more) insulations on the gas side pipes.

●

In case of using at high humidity condition, reinforce insulation of refrigerant pipes.

Surface of insulation may cause dew condition or water dropping, if insulations are not

reinfoced.

Caution

D

Protruding

dimension

Flare die

d

mm

6.35

9.52

12.7

15.88

19.05

For R410A Conventional tool

Pipe dia.

Min. pipe

wall thickness

Protruding dimension for flare, mm

Rigid (Clutch type)

Flare O.D.

Flare nut

tightening torque

0

ー

0.5

0.7

ー

1.3

D

mm

8.9

ー

9.1

12.8

ー

13.2

16.2

ー

16.6

19.3

ー

19.7

23.6

ー

24.0

N·m

14

ー

18

34

ー

42

49

ー

61

68

ー

82

100

ー

120

mm

0.8

0.8

0.8

1

1.2

Refrigerant pipe

250mm

(Section where attached

in a straight line)