-

83

-

'16 • PAC-T-240

PGAO12D405

③

Function Setting by Remote Control (Continued)

④

Trial operation (Continued)

⑤

Control mode switching

⑦

Troubleshooting

④

Trial operation

●

Switch No.

SW2

SW5-1

SW5-2

SW6-1

~

4

SW7

-

1

Control Content

Indoor unit address (0-Fh)

Master/Slave Switching (plural /Slave unit Setting)

Model capacity setting

ON

Operation check, Drain motor test run

OFF

Normal operation

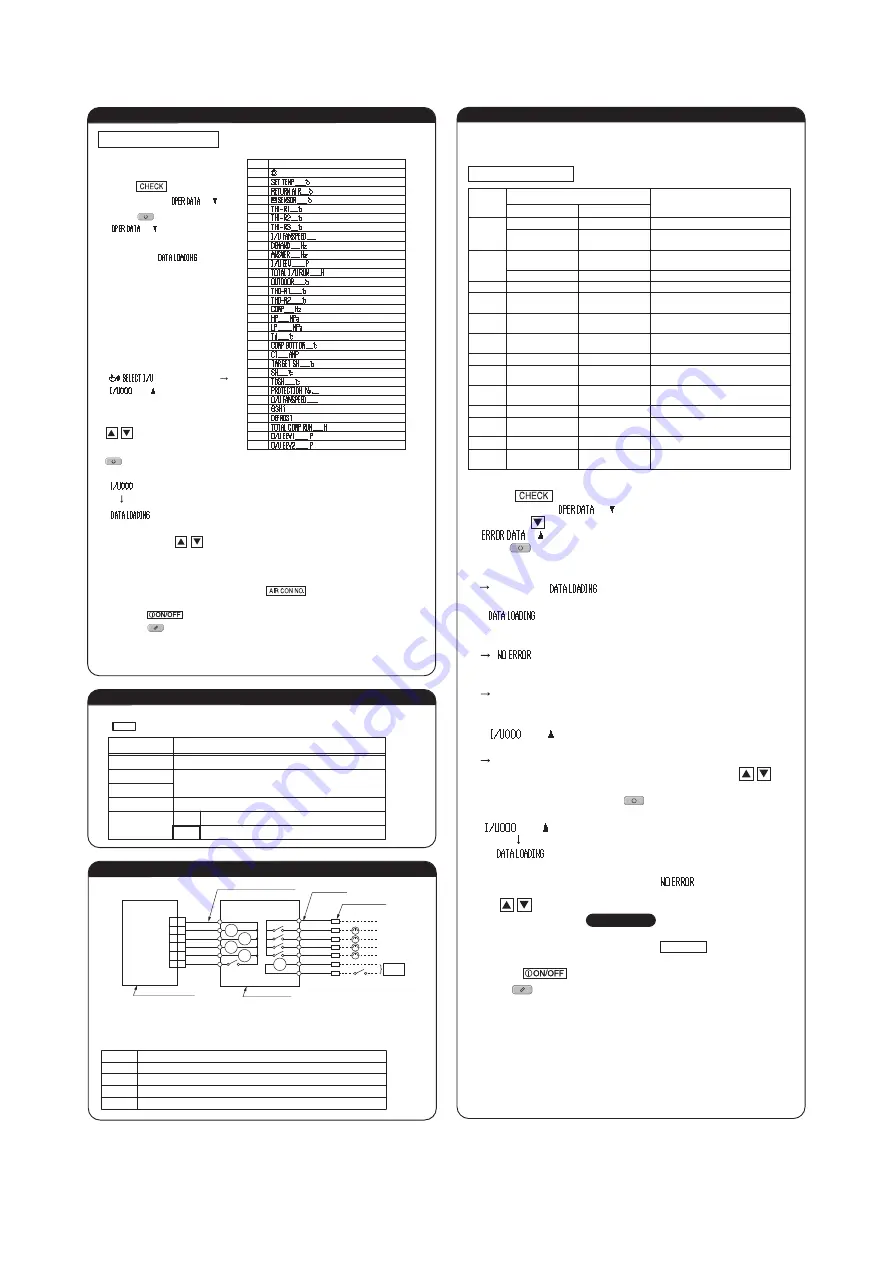

The control content of indoor units can be switched in following way.

( is the default setting)

[Operating procedure]

1. Press the button.

The display change “ ”

2. Once, press the button, and the display change

“ ”.

3. Press the (SET) button and abnormal operation data mode is started.

4. When only one indoor unit is connected to remote control, following is displayed.

①

The case that there is history of abnormal operation.

Error code and “ ” is displayed.

[Example]: [E8] (ERROR CODE)

“ ” is displayed (blinking indication during data loading).

Next, the abnormal operation data of the indoor unit will be displayed. Skip to step 8.

②

The case that there is not history of abnormal operation.

“ ” is displayed for 3 seconds and this mode is closed.

5. When plural indoor units is connected, following is displayed.

①

The case that there is history of abnormal operation.

Error code and the smallest address number of indoor unit among all connected indoor

unit is displayed.

[Example]: [E8] (ERROR CODE)

“ ” blinking

②

The case that there is not history of abnormal operation.

Only address number is displayed.

6. Select the indoor unit number you would like to have data displayed with the

button.

7. Determine the indoor unit number with the (SET) button.

[Example]: [E8] (ERROR CODE)

“ ” (The address of selected indoor unit is blinking for 2 seconds.)

[E8] “ ” (A blinking indication appears while data loaded.)

Next, the abnormal operation data is indicated.

If the indoor unit doing normal operation is selected, “ ” is displayed for 3

seconds and address of indoor unit is displayed.

8. By the button, the abnormal operation data is displayed.

Displayed data item is based on

③

Trial operation

.

※

Depending on models, the items that do not have corresponding data are not displayed.

9. To display the data of a different indoor unit, press the AIR CON No. button, which allows

you to go back to the indoor unit slection screen.

10.Pressing the button will stop displaying data.

Pressing the (RESET) button during remote control unit operation will undo your last

operation and allow you to go back to the previous screen.

◎

If two (2) remote control are connected to one (1) indoor unit, only the master controller is

available for trial operation and confirmation of operation data. (The slave remote control is

not available.)

The operation data is saved when the situation of abnormal operation happen, and the data

can be confirmed by remote control.

Off

E1

E5

E6

E7

E8

E9

E10

E14

E16

E19

E28

Over E30

Off

Off

Off

Not sure

Blinking twice

Blinking once

Blinking once

Blinking once

Blinking once

Off

Blinking for three times

Blinking once

Blinking once

Off

Off

Continuous blinking

Off

Continuous blinking

Not sure

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Continuous blinking

Normal

Fault on power, indoor power off or lack

phase

Fault on the transmission between

indoor circuit board and remote control

Indoor computer abnormal

Fault on outdoor-indoor transmission

Indoor heat exchange sensor interrupted or

short-circuit

Indoor air inhaling sensor broken or

short-circuit

The temperature of heat exchange

abnormal

Float SW actions (only with FS)

Excess number of remote control

connections

The communication fault for master/slave

indoor units

Fan motor abnormal

Configuration fault on running checking

model

Remote control sensor interrupted

Outdoor unit checking (outdoor circuit board

LED checking)

red (che cking)

green (no rmal)

Content

Display on

remote

control

LED on indoor circuit board

Error Code of indoor unit

⑥

Function of CNT connector of indoor printed circuit board

●

CNT connector (local) vendor model

Connector : Made by mol ex

5264 - 06

Terminals : Made by mol ex

5263T

●

Function

Output 1

Output 2

Output 3

Output 4

Input 5

Operation output (there is output when unit is in operation.)

Heating output (there is output when operation MODE is HEATING.)

Compressor ON output (there is output when compressor is in operation.)

Inspection output (there is output when unit is stopped by error.)

Remote operation input (Volt-free contact) (Inputted to operate unit)

Indoor units

control box

Do not use the length over 2 meter

CNT

(Blue 6P)

Common

Output 1

Output 2

Output 3

Output 4

Remote start / stop button or timer point

Butt splice

(Application coverage

0.75

-

1.25mm

2

)

Remote start/stop kit

0.75 mm

2

Note (1) 0.3 mm

2

×2m

Red

Black

Yellow

Blue

Brown

Orange

White

Black

Yellow

Blue

Brown

Orange

Orange

Input

power

+12

PCB (Printed Circuit Board)

×0.2m

XR1

XR1

XR2

XR3

XR4

XR2

XR3

XR4

XR5

1 1

2 2

3 3

4 4

5 5

6 6

[Flow of function setting]

Start

: While indoor unit do not operate, press “ ” (SET) and “ ” (MODE) button for 3 seconds at the same time.

Finalize : Press “ ” (SET) button.

Reset

: Press “ ” (RESET) button.

Select

: Press button.

End

: Press button.

It is possible to finish above setting on the way, and unfinished change of setting is unavailable.

“ ” : Initial settings

“ ” : Automatic criterion

As for detail, refer to the installation manual of remote control.

Only when plu ral indoor units are connected

Indoor N o. selection

01

02

When you use at 50Hz area

When you use at 60Hz area

Automatic operation is impossible

(Remote control function)

Temperature setting button is not working

02

03

03

04

04

05

05

06

06

07

07

08

09

08

10

09

11

10

12

11

13

12

13

14

14

15

16

15

17

16

18

19

Make permission/prohibition control of function be in effect.

Function

setting

Mode button is not working

On/Off button is not working

Fan speed button is not working

Louver button is not working

Timer button is not working

Heating preparation indication should not be indicated.

The filter sign is indicated after running for 180 hours.

The filter sign is indicated after running for 600 hours.

The filter sign is indicated after running for 1000 hours.

The filter sign is indicated after running for 1000 hours, then it will be stopped by compulsion after 24 hours.

If to change the indoor function "04 ",

The remote control function "14 " should be changed accordingly.

Select the louver stop position in four.

The louver can stop at any positon.

With the VRF series, it is used to stop all indoor units connected with the same outdoor unit immediately.

When stop signal is inputed from remote on-off terminal "CNT-6", all indoor units are stopped immediately.

To be reset for pro3.0°C increase in temperature during heating.

To be reset for pro2.0°C increase in temperature during heating.

To be reset for pro1.0°C increase in temperature during heating.

To be reset pro2.0°C increase in return air temperature of indoor unit.

To be reset pro1.5°C increase in return air temperature of indoor unit.

To be reset pro1.0°C increase in return air temperature of indoor unit.

To be reset producing -1.0°C increase in return air temperature of indoor unit.

To be reset producing -1.5°C increase in return air temperature of indoor unit.

To be reset producing -2.0°C increase in return air temperature of indoor unit.

When heating thermostat is off, to be operated with low fan speed. (or with ultra low fan speed in case of some models)

When heating thermostat is off, to be operated with set fan speed.

When heating thermostat is off, to be operated intermittently.

When heating thermostat is off, the fan stops.

When the remote thermistor is working, "FAN OFF" is set automatically.

Do not set when the indoor unit's thermistor is working.

Drain pump is on during cooling and dry.

Drain pump is on during cooling, dry and heating.

Drain pump is on during cooling, dry, heating and fan.

Drain pump is on during cooling, dry and fan.

After cooling is stopped or cooling thermostat is off, the fan does not perform extra operation.

After cooling is stopped or cooling thermostat is off, the fan perform extra operation for half an hour.

After cooling is stopped or cooling thermostat is off, the fan perform extra operation for an hour.

After cooling is stopped or cooling thermostat is off, the fan perform extra operation for six hours.

After heating is stopped or heating thermostat is off, the fan does not perform extra operation.

After heating is stopped or heating thermostat is off,the fan perform extra operation for half an hour.

After heating is stopped or heating thermostat is off,the fan perform extra operation for two hours.

After heating is stopped or heating thermostat is off, the fan perform extra operation for six hours.

During heating is stopped or heating thermostat is off, the fan perform intermittent operation

for five minutes after twenty minutes' off with low airflow.

During heating is stopped or heating thermostat is off, the fan perform intermittent operation

for five minutes after five minutes' off with low airflow.

Items marked with

★

are not available on the floor standing FDF.

Do not change the initial setting

Working only with the single split series.

To control frost prevention, the indoor fan tap is raised.

Change of indoor heat exchanger temperature to start frost prevention control.

Function

setting

Remote thermistor is not working.

Remote thermistor is working.

Remote thermistor is working, and to be set for pro3.0°C increase in temperature.

Remote thermistor is working, and to be set for pro2.0°C increase in temperature.

Remote thermistor is working, and to be set for pro1.0°C increase in temperature.

Remote thermistor is working, and to be set for producing -1.0°C increase in temperature.

Remote thermistor is working, and to be set for producing -2.0°C increase in temperature.

Remote thermistor is working, and to be set for producing -3.0°C increase in temperature.

If you want to change the remote control function "14 ",

You must change the indoor function "04 " accordingly.

You can select the louver stop position in the four.

The louver can stop at any position.

Temperature indication is by degree C

Temperature indication is by degree F

If to change re-set with other indoor

unit, push AIRCON NO.

button, and indoor selection indication

(for example: I/U 000) is set back.

Consult the technical data etc .for each control details

Record and s ave the

setting

(Note3)

(Note2)

Connect the Single split series and the VRF series to the indoor board CNT and indoor board CND respectively. If a

ventilation device is connected, been geared with the motion of indoor device, the ventilation device is operated/stopped.

By connecting the ventilation device with the Single split series device to indoor board CNT, the VRF series device to

CND, you can operate/stop the ventilation device independently by the handling of ventilation button.

If you change the range of set temperature, the indication of set temperature will vary following the control.

If you change the range of set temperature, the indication of set temperature will not vary following the control, and

keep the set temperature.

If you input into the indoor printed circuit board CNT from outside, the indoor device will be operated independently

following the input from outside.

If you input into indoor printed circuit board CNT from outside, All units which share the same one remote control

network work following the input from outside.

During air-conditioner stopping push

(SET) + (MODE) button

simultaneously for 3 seconds

In normal working indication, indoor unit temperature is indicated instead of airflow.

(Only the master remote control can be indicated. )

(Indoor unit function)

Airflow of fan becomes the three speed of - - or - - - .

Airflow of fan becomes the two speed of - .

Airflow of fan becomes the two speed of - .

Airflow of fan is fixed at one speed.

★

★

★

★

★

★

★

ON/OFF button (finished)

The method of trial cooling operation

Operate the remote control unit as follows.

1. Starting a cooling test run.

①

Start the system by pressing the button.

②

Select “ (Cool)” with the (MODE) button.

③

Press the

TEST

button for 3 seconds or longer.

The screen display will switch to: “ ”

④

When the (SET) button is pressed while “ ” is indicated, a cooling test

run will start.

The screen display will switch to “ ”.

2. Ending a cooling test run.

Pressing the button, the (TEMP) button or (MODE) button will end a

cooling test run. (Cooling test run will end after 30 minutes pass.)

“ ” shown on the screen will go off.

Operation data can be checked with remote

control unit operation.

1. Press the button.

The display change “ ”

2. Press the (SET) button while

“ ” is displayed.

3.

When only one indoor unit is connected to

remote control, “ ” is

displayed (blinking indication during data

loading).

Next, operation data of the indoor unit

will be displayed. Skip to step 7.

4. When plural indoor units is connected, the

smallest address number of indoor unit

among all connected indoor unit is displayed.

[Example]:

“ ” (blinking 1 seconds)

“ ” blinking.

5. Select the indoor unit number you would

like to have data displayed with the

button.

6. Determine the indoor unit number with the

(SET) button.

(The indoor unit number changes from blinking indication to continuous indication)

“ ” (The address of selected indoor unit is blinking for 2 seconds.)

“ ” (A blinking indication appears while data loaded.)

Next, the operation data of the indoor unit is indicated.

7. Upon operation of the button, the current operation data is displayed in order from data

number 01.

The items displayed are in the above table.

※

Depending on models, the items that do not have corresponding data are not displayed.

8. To display the data of a different indoor unit, press the button, which allows you to go back to

the indoor unit selection screen.

9. Pressing the button will stop displaying data.

Pressing the (RESET) button during remote control unit operation will undo your last operation and

allow you to go back to the previous screen.

◎

If two (2) remote control are connected to one (1) inside unit, only the master controller is available for trial

operation and confirmation of operation data. (The slave remote control is not available.)

Checking operation data

Number

01

02

03

04

05

06

07

08

09

10

11

12

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Data Item

(Ope ration Mode)

(Set Temperature)

(Return Air Temperature)

(Remote Control ThermistorTemperature)

(Indoor Unit Heat Exchanger Thermistor / U Bend)

(Indoor Unit Heat Exchanger Thermistor /Capillary)

(Indoor Unit Heat Exchanger Thermistor /Gas Header)

(Indoor Unit Fan Speed)

(Frequency Requirements)

(Response Frequency)

(Pulse of Indoor Unit Expansion Value)

(Total Running Hours of The Indoor Unit)

(Outdoor Air Temperature)

(Outdoor Unit Heat Exchanger Thermistor)

(Outdoor Unit Heat Exchanger Thermistor)

(Compressor Frequency)

(High Pressure)

(Low Pressure)

(Discharge Pipe Temperature)

(Comp Bottom Temperature)

(Current)

(Target Super Heat)

(Super Heat)

(Discharge Pipe Super Heat)

(Protection State N o. of The Compressor)

(Outdoor Unit Fan Speed)

(63H1 On/Off)

(Defrost Control On/Off)

(Total Running Hours of The Compressor)

(Pulse of The Outdoor Unit Expansion Valve EEVC)

(Pulse of The Outdoor Unit Expansion Valve EEVH)

※

Depending on outdoor unit model, there are data not shown.