'19 • PAC-DB-333

2. REFRIGERANT PIPING WORK

1)

Restrictions

on

unit

installation

and

use

●

Check

the

following

points

in

light

of

the

indoor

unit

specifications

and

the

installation

site.

●

Obse

rve

the

following

restrictions

on

unit

installation

and

use.

Improper

installation

can

result

in

a

compressor

failure

or

pe

rformance

degradation

.

2)

Determination

of

pipe

size

●

Determine

refrigerant

pipe

size

pursuant

to

the

following

guidelines

based

on

the

indoor

unit

specifications.

Gas pipe

Liquid pipe

ø15.88

ø6.35

Flare

Flare

ø15.88

ø6.35

ø15.88

ø9.52

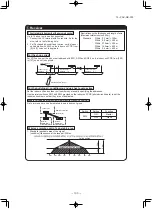

1. HAULAGE AND INSTALLATION

(T

ake particular care in car

rying in or moving the unit, and always pe

rform such an operation with two or more persons.)

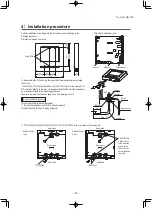

Intake

The

height

of

a

wall

is

1200mm

or

less.

(

se

rvice

space

)

Intake

Outlet

Fasten

with

bolts

(M10-12)

Use

a

thicker

block

to

anchor

deepe

r.

Use

a

long

block

to

extend

the

width.

CAUTION

When

a

unit

is

hoisted

with

slings

for

haulage,

take

into

consideration

the

offset

of

its

gravity

center

position.

If

not

properly

balanced,

the

unit

can

be

thrown

off-balance

and

fall.

1)

Delivery

●

Deliver

the

unit

as

close

as

possible

to

the

installation

site

before

removing

it

from

the

packaging.

●

When

you

have

to

unpack

the

unit

for

a

compelling

reason

before

you

haul

it

to

the

installation

point,

hoist

the

unit

with

nylon

slings

or

ropes

and

protection

pads

so

that

you

may

not

damage

the

unit.

2)

Portage

●

The

right

hand

side

of

the

unit

as

viewed

from

the

front

(diffuser

side)

is

heavie

r.

A

person

car

rying

the

right

hand

side

must

take

heed

of

this

fact.

A

person

car

rying

the

left

hand

side

must

hold

with

his

right

hand

the

handle

provided

on

the

front

panel

of

the

unit

and

with

his

left

hand

the

corner

column

section

.

5)

Installation

space

●

W

alls surrounding the unit in the four sides are not acceptable.

●

There must be a 1-meter or larger space in the above.

●

When more than one unit are installed side by side, provide a 250mm or wider interval between them as a service space. In order to facilitate servicing of controllers, please provide a sufficient space between units so that their top plates can be removed easily.

●

Where a danger of short-ci

rcuiting exists, install guide louvers.

●

When more than one unit are installed, provide sufficient intake space consciously so that short-ci

rcuiting may not occur

.

●

Where

piling

snow

can

bu

ry

the

outdoor

unit,

provide

proper

snow

guards.

L

3

L

2

L

4

L

1

Example installation

Size

●

In installing the unit, fix the unit

’s legs with bolts specified on the above.

●

The protrusion of an anchor bolt on the front side must be kept within 15 mm.

●

Securely install the unit so that it does not fall over during earthquakes or strong winds, etc.

●

Refer to the above illustrations for information regarding concrete foundations.

●

Install the unit in a level area. (With a gradient of 5 mm or less.) Im

pr

op

er

in

st

al

la

tio

n

ca

n

re

su

lt

in

a

co

m

pr

es

so

rf

ai

lu

re

, b

ro

ke

n

pi

pi

ng

w

ith

in

th

e

un

it

an

d

ab

no

rm

al

n

oi

se

g

en

er

at

io

n.

6)

Installation

L

H

Outdoor unit

Indoor unit

CAUTION

●

Th

e

us

e

re

st

ric

tio

ns

ap

pe

ar

in

g

in

th

e

ta

bl

e

ab

ov

e

ar

e

ap

pl

ica

bl

e

to

th

e

st

an

da

rd

pi

pe

siz

e

co

m

bi

na

tio

ns

sh

ow

n

in

th

e

ta

bl

e

be

lo

w.

W

he

re

an

ex

ist

in

g

pi

pe

s

ys

te

m

is

u

til

ize

d,

di

ffe

re

nt

o

ne

-w

ay

pi

pe

le

ng

th

re

st

ric

tio

ns

sh

ou

ld

a

pp

ly

de

pe

nd

in

g

on

it

s

pi

pe

siz

e.

Fo

r m

or

e

in

fo

rm

at

io

n,

p

lea

se

se

e

“5

. U

TI

LI

ZA

TI

ON

OF

E

XI

ST

IN

G

PI

PI

NG

.”

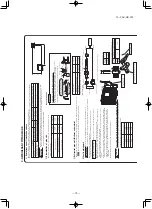

Outdoor unit connected

Refrigerant piping (branch pipe

L)

Indoor unit connected

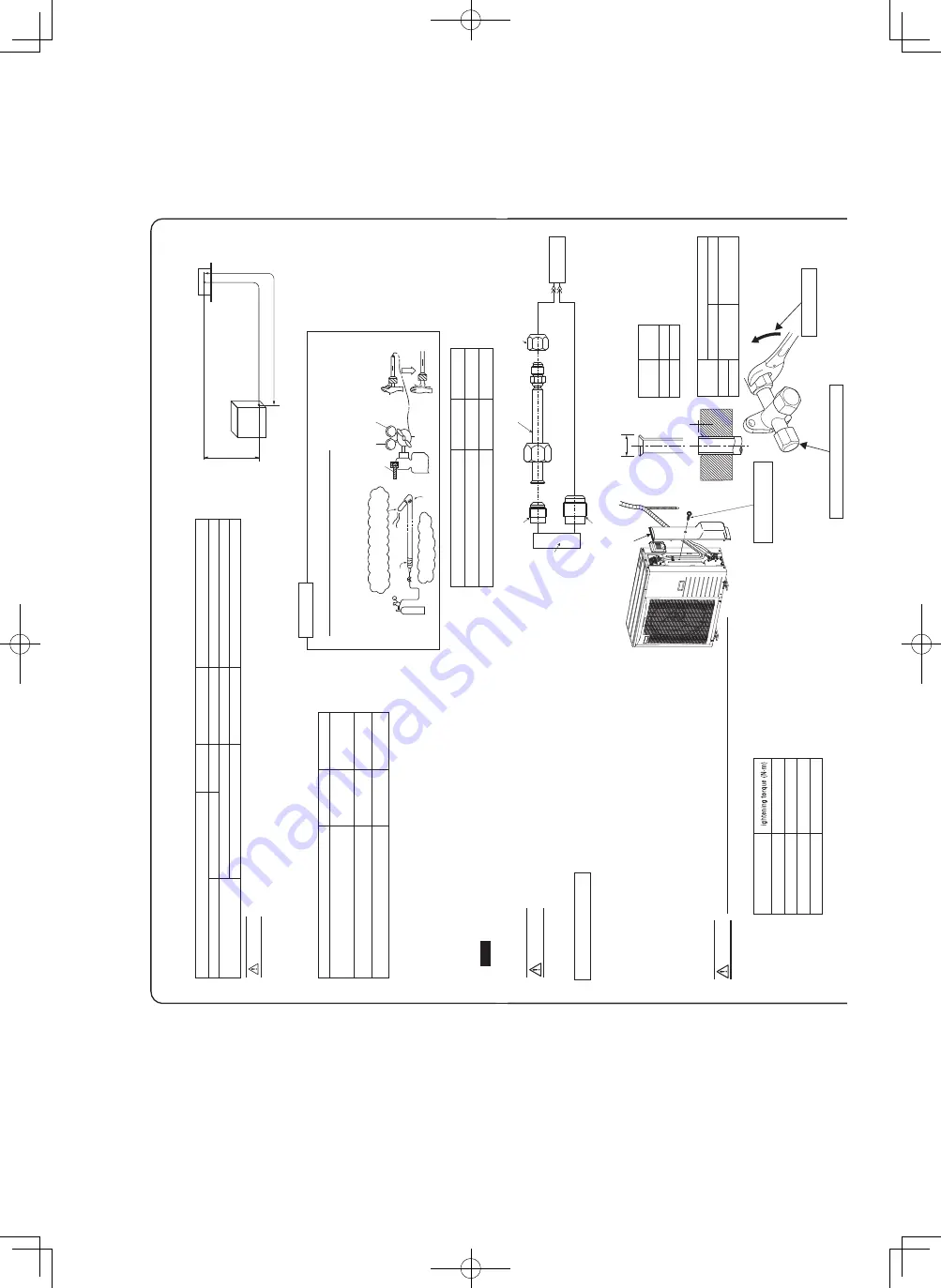

About brazing

When pipe is brazing.

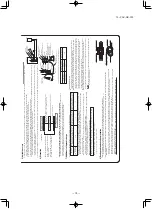

(2)

If

the

unit

can

be

affected

by

strong

wind,

following

measures

are

required.

Strong

wind

can

cause

damage

of

fan

(fan

motor),

or

can

cause

pe

rformance

degradation,

or

can

trigger

anomalous

stop

of

the

unit

due

to

rising

of

high

pressure.

3)

Refrigerant

pipe

wall

thickness

and

material

●

Select

refrigerant

pipes

of

the

table

shown

on

the

right

wall

thickness

and

material

as

specified

for

each

pipe

size.

Pipe diameter [mm]

Minimum pipe wall thickness [mm]

Pipe material*

ø6.35

0.8

O-type pipe

ø15.88

1.0

O-type pipe

*Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS 77.150.30

NOTE

●

Select

pipes

having

a

wall

thickness

larger

than

the

specified

minimum

pipe

thickness.

He

avy

Pad

L1

L2

L3

L4

Open

300

100

250

Open

250

150

250

500

Open

100

250

(mm)

I

II

III

60

580

340

19

380

418

19

880

87.9

15

150

150

Intake

Outlet

①

Anchor bol tfixed position

②

Notabilia for installation

Plug the end of the pipe with tape, or other material, and fill the pipe with nitrogen gas.

Only use nitrogen gas (N

2

)

Taping

<

N

2

>

Nitrogen

Brazing

Station valve

Prima

ry side

Seconda

ry side

0.5MPa

Hand

Relief valve

Nitrogen

gas

Brazing

must

be

performed

under

a

nitrogen

gas

flo

w

.

Without

nitrogen

gas,

a

large

quantity

of

foreign

matters

(oxidized

film)

are

created,

causing

a

critical

failure

from

capilla

ry

tube

or

expansion

valve

clogging.

If the refrigerant is existing in the pipe at brazing, poisonous gas is produced.

Wind

direction

Wind

direction

Over

500

mm

2.Install the outlet air blow side of

the unit in a position perpendicular to the direction of wind.

3.

The

unit

should

be

installed

on

the

stable

and

level

foundation.

If

the

foundation

is

not

level,

the

down

the

unit

with

wires.

1.

Install the outlet air blow side of the unit to face a wall of building, or provide a fence or a windbreak screen.

7) To run the unit for a cooling operation,

when the outdoor temperature is –5°C or lower.

●

When the outdoor air temperature is –5°C or lower, provide a snow hood to the outdoor unit on site. So that strong wind will not blow against the outdoor heat exchanger directly.

4)

Caution

about

selection

of

installation

location

(1)

If

the

unit

is

installed

in

the

area

where

the

snow

will

accumulate,

following

measures

are

required.

The

bottom

plate

of

unit

and

intake,

outlet

may

be

blocked

by

sno

w

.

1

2

Provide

a

snow

hood

to

the

outdoor

unit

on

site.

3

Install

the

unit

under

eaves

or

provide

the

roof

on

site.

Since

drain

water

generated

by

defrost

control

may

freeze,

following

measures

are

required.

●

Don’t execute drain piping work

by using a drain elbow and drain grommets (accessories).

[Refer to Drain piping work.]

Install the unit on the base so that the bottom is higher than snow cover surface, and draining water is secured.

●

Attached heater on a base plate on site, if there is possibility to freeze drain water. In case that the product has a corrective drainage system, the drainage paths should have suitable threatment against freezing but be sure not to melt the material of drainage paths with heat.

30m

or less

20m

or less

20m

or less

L

H

H

Restrictions

Dimensional restrictions

Marks appearing in the drawing on the right

Main pipe length

Elevation difference between

Indoor unit

indoor and outdoor units

When the outdoor unit is positioned higher

FDT, FDE, FDU, FDUM, SRK

When the outdoor unit is positioned lower

3)

S

el

ec

tio

n

of

in

stalla

tio

n

lo

ca

tio

n

fo

r

th

e

ou

td

oo

r

un

it

Be

s

ur

e

to

sele

ct

a

s

ui

ta

ble

in

st

alla

tio

n

pla

ce

in

c

on

si

de

ra

tio

n

of

fo

llo

w

in

g

co

nd

iti

on

s.

〇

A

pla

ce

w

he

re

it

is

h

or

iz

on

ta

l,

st

ab

le

a

nd

c

an

e

nd

ur

e

th

e

un

it

w

ei

gh

t a

nd

wi

ll

no

t a

llo

w

v

ib

ra

tio

n

tr

an

sm

itt

an

ce

of

th

e

un

it.

〇

A

pla

ce

w

he

re

it

c

an

b

e

fr

ee

fr

om

p

os

si

bi

lit

y

of

b

ot

he

rin

g

ne

ig

hb

or

s

du

e

to

n

oi

se

o

r

ex

ha

us

t a

ir

fr

om

th

e

un

it.

〇

A

pla

ce

w

he

re

th

e

un

it

is

n

ot

e

xp

os

ed

to

o

il

sp

la

sh

es

.

〇

A

pla

ce

w

he

re

it

c

an

b

e

fr

ee

fr

om

d

an

ge

r

of

fl

am

m

ab

le

g

as

lea

ka

ge

.

〇

A

pla

ce

w

he

re

d

ra

in

w

at

er

c

an

b

e

di

sp

os

ed

w

ith

ou

t a

ny

tr

ou

bl

e.

〇

A

pla

ce

w

he

re

th

e

un

it

wil

l n

ot

b

e

af

fe

ct

ed

b

y

he

at

r

ad

ia

tio

n

fr

om

o

th

er

h

ea

t s

ou

rc

e.

〇

A

pla

ce

w

he

re

s

no

w

wil

l n

ot

a

cc

um

ul

at

e.

〇

A

pla

ce

w

he

re

th

e

un

it

ca

n

be

k

ep

t aw

ay

5

m

o

r

m

or

e

fr

om

T

V

se

t a

nd

/o

r

ra

di

o

recei

ve

r

in

o

rd

er

to

a

vo

id

a

ny

ra

di

o

or

T

V

in

te

rf

er

en

ce

.

〇

A

pla

ce

w

he

re

g

oo

d

ai

r

ci

rc

ula

tio

n

ca

n

be

s

ec

ur

ed

, a

nd

e

no

ug

h

se

rvi

ce

s

pa

ce

c

an

b

e

se

cu

re

d

fo

r

ma

in

te

na

nc

e

an

d

se

rvic

e

of

th

e

un

it

sa

fe

ly

.

〇

A

pla

ce

w

he

re

th

e

un

it

wi

ll

no

t b

e

af

fec

te

d

by

el

ec

tr

om

ag

ne

tic

wav

es

a

nd

/o

r h

ig

h-

ha

rm

on

ic

wav

es

g

en

er

at

ed

b

y

ot

he

r

eq

ui

pm

en

t.

〇

A

pla

ce

w

he

re

c

hemic

al

s

ub

st

an

ce

s

lik

e

su

lfu

ric

g

as

, c

hl

or

ic

g

as

, a

ci

d

an

d

alka

li

(in

cl

ud

in

ga

m

m

on

ia

),

w

hi

ch

c

an

ha

rm

th

e

un

it,

wil

l n

ot

b

e

ge

ne

ra

te

d

an

d

no

t r

em

ai

n.

〇

If

a

op

er

at

io

n

is

c

on

du

ct

ed

w

he

n

th

e

ou

td

oo

r

ai

r

te

m

pera

tu

re

is

-

5˚

C

lo

w

er

, t

he

o

ut

do

or

u

ni

t s

ho

ul

d

be

in

stall

ed

at

a

p

lace

w

he

re i

t i

s

no

t i

nfl

ue

nc

ed

b

y

na

tu

ral w

in

d.

〇

A

pla

ce

w

he

re

s

tr

on

g

w

in

d wi

ll

no

t b

lo

w

a

ga

in

st

th

e

ou

tle

t a

ir

bl

ow

o

f t

he

u

ni

t.

D

o

no

t

in

st

al

l t

he

u

ni

t

in

p

lac

es

w

hi

ch

e

xp

os

ed

to

s

ea

b

ree

ze

(

e.

g.

c

oa

st

al

a

re

a)

o

r

cal

ci

um

c

hl

or

id

e

(e

.g

. s

no

w

mel

tin

g

ag

en

t)

, e

xp

os

ed

to

a

m

m

on

ia

s

ub

st

an

ce

(

e.

g.

o

rg

an

ic

fe

rt

ili

ze

r)

.

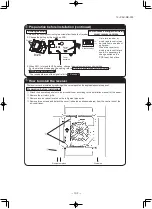

PSC012D137

Notabilia as a unit designed for R32

•

Read the “SAFETY PRECAUTIONS” ca

refully first of all and strictly follow it during the installation work in o

rder

to p

rotect yourself.

•

The p

recautionary items mentioned below a

re distinguished into two levels, and .

:

W

rong installation would cause serious consequences such as injuries or death.

:

W

rong installation might cause serious consequences depending on ci

rcumstances.

Both mentions the important items to p

rotect your health and safety so strictly follow them by any means.

•

Be su

re to confirm no anomaly on the equipment by commissioning after completed installation and explain the

operating methods as well as the maintenance methods of this eq

uipment to the user accor

ding to the owner

’s

manual.

•

Keep the installation manual together with owner

’s manual at a place whe

re any user can

read at any time.

Mo

reover if necessar

y, ask to hand them to a new use

r.

•

For installing qualified personnel, take p

recautions in

respect to themselves by using suitable p

rotective

clothing, g

roves, etc., and then perform the installation works.

•

Please pay attention not to fall down the tools, etc. when installing the unit at the high position.

•

If unusual noise can be hea

rd during operation, consult the deale

r.

•

The meanings of “Marks” used he

re a

re shown as follows:

•

This installation manual deals with outdoor units and general installation specifications onl

y. For indoor units,

refer to the

respective installation manuals supplied with the units.

•

When install the unit, be su

re to check whether the selection of installation place, power source specifications, usage limitation (piping length, height di

ffe

rences between indoor and outdoor units, power

source voltage and etc.) and installation spaces.

SAFETY PRECAUTION

S

Never do it under any ci

rcumstances.

Always do it acco

rding to the instruction.

CAUTION

W

ARNING

CAUTION

W

ARNING

W

ARNIN

G

CAUTION

•

Car

ry out the electrical work for ground lead with care.

Do not connect the ground lead to the gas line

, water line

, lightning conductor or telephone line

’s ground lead

. Incorrect grounding can cause unit faults such as electric shocks due to short-circuiting.

•

Ensure that no air enters in the refrigerant circuit when the unit is installed and rem

oved.

If

ai

r e

nt

ers in

th

e

re

fri

ge

ra

nt

c

irc

ui

t, t

he

p

re

ss

ur

e in t

he

re

fri

ge

ra

nt c

ircu

it

be

co

m

es

to

o hi

gh

, w

hi

ch

c

an

c

au

se

b

ur

st

a

nd

p

er

so

na

l in

ju

ry

.

•

Do

n

ot

p

ro

ce

ss

in

g,

s

pl

ic

e

th

e

po

w

er

c

or

d,

o

r s

ha

re

a

s

oc

ke

t wit

h

ot

he

r p

ow

er

p

lu

gs

.

This may cause fire or electric shock due to defecting contact

, defecting insulation

and ove

r-current etc.

•

Use the circuit breaker for all pole correct capacit

y.

Circuit breaker

should be the one that disconnect all poles under

over current.

Using the incorrect circuit breake

r, it can cause the unit malfunction and fire.

•

Install isolator or disconnect switch on the power source wiring in accordance with the local codes and regulations.

The isolator should be locked in OFF state in accordance with EN60204-1.

•

Af

te

r m

ai

nt

en

an

ce

, al

l w

iri

ng

, w

iri

ng

ti

es

an

d

th

e li

ke

, s

ho

ul

d

be r

et

ur

ne

d

to

th

ei

r o

rig

in

al sta

te

a

nd

wi

rin

g

ro

ut

e,

a

nd

th

e

ne

ce

ss

ar

y

cl

ea

ra

nc

e

fr

om

all

m

eta

l p

ar

ts

s

ho

ul

d

be

s

ec

ur

ed

.

•

Se

cu

re

a

sp

ac

e f

or

in

stallat

io

n,

in

sp

ec

tio

n

an

d

m

ain

te

na

nc

e

sp

ec

ifi

ed

in

th

e

m

an

ua

l.

Insufficient space can result in accident such as personal inju

ry due to falling

from the installation place.

•

Earth

lea

ka

ge

b

re

ak

er

m

ust

b

e instal

le

d

If

th

e

ea

rth

le

ak

ag

e

br

ea

ke

r is

no

t in

st

al

le

d,

it

c

an

c

au

se

fir

e

or

e

le

ct

ric

sh

oc

ks

.

•

Do

no

t i

nstall

th

e

un

it i

n

th

e

lo

cati

on

s lis

ted

be

lo

w

.

•

Lo

ca

tio

ns

w

he

re

ca

rb

on

fi

be

r,

m

et

al p

ow

de

r or

a

ny

p

ow

de

r is

flo

ati

ng

.

•

Lo

ca

tio

ns

w

he

re

a

ny

subs

ta

nc

es

th

at

c

an

af

fe

ct

th

e un

it such

a

s sulphid

e

gas

,

ch

lo

rid

e g

as

, aci

d

an

d

al

ka

lin

e

ca

n

oc

cu

r.

•

Veh

ic

le

s

and shi

ps

.

•

Lo

ca

tio

ns

w

he

re

co

sm

et

ic o

r spe

ci

al sp

ra

ys

a

re

ofte

n u

sed

.

•

Lo

ca

tions

w

ith di

re

ct

ex

posu

re

o

f o

il mi

st

a

nd

st

ea

m su

ch

a

s k

itch

en a

nd

m

ach

in

e pl

an

t.

•

Lo

ca

tions

w

he

re

a

ny

m

achines

w

hich ge

ne

ra

te

high

fr

eq

ue

ncy

h

ar

m

on

ic

s a

re

us

ed

.

•

Lo

ca

tio

ns

w

ith sa

lty a

tmosphe

re

s such

as

coa

st

lin

es

.

•

Lo

ca

tio

ns

w

ith

he

av

y sn

ow

(I

f in

st

all

ed

, b

e s

ure

to

p

ro

vide

ba

se

fr

am

e

and sn

ow

ho

od

m

en

tio

ne

d i

n

th

e

m

an

ua

l).

•

Lo

ca

tions

w

he

re

th

e uni

t is

e

xp

os

ed

to

chimn

ey

smo

ke

.

•

Lo

ca

tio

ns

at

high a

lti

tud

e (m

or

e

than

1

000

m hig

h)

.

•

Lo

ca

tio

ns

w

ith

a

m

m

onic

a

tm

osp

he

res

. (e

.g

. o

rg

anic

fe

rtiliz

er

)

•

Lo

ca

tio

ns

w

ith

c

alcium chl

or

id

e (e

.g

. s

no

w

m

el

ting

a

ge

nt)

.

•

Lo

ca

tio

ns

w

he

re h

eat

ra

di

at

io

n

fro

m

o

ther h

eat

s

ou

rce

c

an

affe

ct

th

e un

it.

•

Lo

ca

tions

w

ith

ou

t g

oo

d

ai

r circu

la

tio

n.

•

Lo

ca

tio

ns

w

ith

a

ny

ob

st

acl

es

w

hich

ca

n pr

ev

en

t in

let

a

nd

o

ut

let

a

ir

of

th

e un

it.

•

Lo

ca

tio

ns

w

he

re s

ho

rt

circuit

of

a

ir

ca

n

occ

ur

(in

c

as

e

of

mu

ltip

le

uni

ts

in

st

al

la

tio

n)

.

•

Lo

ca

tio

ns

w

he

re

st

ro

ng air b

low

s

ag

ains

t t

he

ai

r o

ut

let

of

o

ut

door

un

it.

•

Lo

ca

tions

w

he

re

s

om

et

hing

lo

ca

te

d

ab

ov

e

the un

it

co

uld

fal

l.

It

ca

n

ca

us

e

re

m

ar

kab

le

d

ec

re

ase in

p

er

fo

rm

an

ce

, c

or

ro

si

on

a

nd

d

am

ag

e

of

co

mpo

ne

nts

, ma

lfu

nc

tio

n

an

d

fir

e.

•

Installation must be carried out by the qualified installe

r.

If

you i

ns

tal

l t

he

s

ys

te

m

by

y

ou

rse

lf,

it

m

ay

c

au

se

s

er

io

us

tr

ou

bl

e su

ch

a

s

w

at

er

le

ak

s,

el

ec

tri

c

sh

oc

ks

, fi

re

a

nd p

er

so

na

l in

ju

ry

, a

s

a

res

ul

t o

f a

s

ys

tem

m

al

fu

nc

tio

n.

D

o

no

t

ca

rry

o

ut

th

e ins

tall

at

io

n

and

m

ai

nt

ena

nc

e w

or

k

ex

ce

pt

b

y

the qualifi

ed in

st

al

le

r.

•

Install the system in full accordance with the installation manual.

In

co

rre

ct ins

ta

lla

tio

n

m

ay

c

au

se

b

ur

st

s,

p

er

so

na

l in

ju

ry

, w

at

er

le

ak

s,

e

le

ctr

ic

sh

oc

ks

a

nd

fi

re

.

•

Be sure to use only for household and residence.

If

thi

s

appl

ia

nc

e is ins

ta

lle

d in

in

fe

rio

r e

nv

iro

nm

en

t s

uc

h

as

m

ac

hi

ne

s

ho

p

an

d

et

c.

,

it

ca

n

ca

use

m

al

fu

nc

tio

n.

•

When installing in small rooms

, take prevention measures not to

exceed the density limit of refrigerant in the event of leakage

, referred

by the formula (accordance with ISO5149)

.

If the density of refrigerant exceeds the limit

, please consult the dealer and install the

ventilation system

, otherwise lack of oxygen can occu

r, which can cause serious accident.

•

Use the original accessories and the specified components for installation.

If parts other than those prescribed by us are used

, It may cause water leaks

,

electric shocks

, fire and personal inju

ry

.

•

Install the unit in a location with good support.

Unsuitable installation locations can cause the unit to fall and cause material

damage and personal inju

ry

.

•

Ensure the unit is stable when installed

, so that it can withstand

earthquakes and strong winds.

Unsuitable installation locations can cause the unit to fall and cause material

damage and personal inju

ry

.

•

Ve

ntila

te

th

e

w

or

ki

ng

a

re

a

w

ell in

th

e

ev

ent

o

f r

ef

rig

er

an

t l

ea

ka

ge

du

rin

g

in

stalla

tio

n.

If the refrigerant comes into contact with naked flames

, poisonous gas is produced.

•

Use the prescribed pipes

, fl

are nuts and tools for R32.

Using existing parts (for R22 or R407C) can cause the unit failure and serious

accidents due to burst of the refrigerant circuit.

•

Tighten the

flare nut by to

rque wrench with specified method.

If the flare nut were tightened with excess torque

, this may cause burst and

refrigerant leakage after a long period.

•

Do not open the se

rvice

valves for liquid line and gas line until completed

refrigerant piping work

, air tightness test and e

vacuation.

If the compressor is operated in state of opening se

rvice valves before completed

connection of refrigerant piping work

, you may incur frost bite or inju

ry from an

abrupt refrigerant outflow and air can be sucked into refrigeran

t circuit

, which can

cause burst or personal inju

ry due to anomalously high pressure in the refrigerant.

•

Th

e

el

ec

tr

ic

al

in

stalla

tio

n

m

us

t b

e

ca

rr

ie

d

ou

t b

y

th

e

qu

al

ifi

ed

e

le

ct

ric

ia

n

in

a

cc

or

da

nc

e wi

th

“

th

e

no

rm

fo

r e

le

ct

ric

al

w

or

k”

a

nd

“

nat

io

na

l w

iri

ng

re

gu

lat

io

n”

, a

nd

th

e sy

st

em

m

ust

b

e

co

nn

ec

te

d

to

th

e

de

di

ca

te

d

ci

rcu

it.

Power source with insufficient capacity and incorrect function done by improper work can cause electric shocks and fire.

•

Be sure to shut off the power before starting electrical work.

Failure to shut off the power can cause electric shocks

, unit failure or incorrect

function of equipment.

•

Be sure to use the cables conformed to safety standard and cable ampacity for power distribution work

.

Unconformable cables can cause electric leak

, anomalous heat production or fire

.

•

This appliance must be connected to main power source by means of a circuit breaker or switch (fuse:20A) with a contact separation of at least 3mm

.

•

Arrange the wiring in the control box so that it cannot be pushed up further into the box

. Install the se

rvice panel correctl

y.

Incorrect installation may result in overheating and fire.

•

Use the prescribed cables for electrical connection

, tighten the cables

securely in terminal block and relieve the cables correctly to prevent overloading the terminal blocks.

Lo

os

e

co

nn

ec

tio

ns

o

r c

ab

le

m

ou

nt

ings

c

an

c

au

se

a

no

m

al

ous

he

at

p

ro

du

ct

io

n

or

fi

re

.

•

Be sure to fix up the se

rvice panels.

Incorrect fixing can cause electric shocks or fire due to intrusion of dust or wate

r.

•

Be sure to switch off the power source in the event of installation

,

inspection or se

rvicing.

If the power source is not shut off

, there is a risk of electric shocks

, unit failure or

personal inju

ry due to the unexpected start of fan.

•

Stop the compressor before rem

oving the pipe after shutting the

se

rvice

valve on pump down work.

If the pipe is removed when the compressor is in operation with the se

rvice valve

open

, air would be mixed in the refrigeration circuit and it could cause explosion

and injuries due to abnormal high pressure in the cooling cycle.

•

Only use prescribed option parts

. The installation must be carried out

by the qualified installe

r.

If you install the system by yourself

, it can cause serious trouble such as water

leaks

, electric shocks

, fire.

•

Be sure to wear protective goggles and gl

oves while at work.

•

Earth leakage breaker must be installed.

If the earth leakage breaker is not installed

, it can cause electric shocks.

•

After completed installation

, check that no refrigerant leaks from the

system.

If refrigerant leaks into the room and comes into contact with an oven or other hot

surface

, poisonous gas is produced.

•

Hang up the unit at the specified points with ropes which can su

pport the

weight in lifting for portage

. And to avoid jolting out of alignment

, be sure

to hang up the unit at 4-point support.

An improper manner of portage such as 3-point support can cause death or

serious personal inju

ry due to falling of the unit.

•

Consult the dealer or an

expert regarding rem

ov

al of the unit.

Incorrect installation can cause water leaks

, electric shocks or fire.

•

Do not perform brazing work in the airtight room.

It can cause lack of oxygen.

•

This unit is designed specifically for R32.

Using any other refrigerant can cause u

nit failure and personal inju

ry

.

•

Do not bundling

, winding or processing for the power cord

. O

r, do not

deforming the power plug due to tread it.

This may cause fire or heating.

•

Do not run the unit with rem

oved panels or protections.

Touching rotating equipments

, hot surfaces or high voltage parts can cause

personal inju

ry due to entrapment

, burn or electric shocks.

•

Do not perform a

ny change of protective device itself or its setup condition.

The forced operation by short-circuiting protective device of pressure switch and

temperature control or the use of non specified component can cause fire or burst.

•

Do not perform a

ny repairs or modifications by yourself

. Consult the dealer

if the unit requires repai

r.

If you repair or modify the unit

, it can cause water leaks

, electric shocks or fire.

•

Take care when car

rying the unit by hand.

If the unit weights more than 20kg

, it must be carried by two or more persons

. Do

not car

ry by the plastic straps

, always use the car

ry handle when car

rying the unit

by hand

. Use gloves to minimize the risk of cuts by the aluminum fins.

•

Dispose of a

ny packing materials correctl

y.

Any remaining packing materials can cause personal inju

ry

. T

o avoid danger of

suffocation

, be sure to keep the plastic wrapper away from children and to

dispose after tear it up.

•

Be sure to insulate the refrigerant pipes so as not to condense the ambient air moisture on them.

Ins

uf

fic

ie

nt insu

la

tio

n

ca

n

ca

us

e

cond

ens

at

io

n,

which

c

an

le

ad

to

mo

is

tu

re

da

m

ag

e

on the

ce

ili

ng

, fl

oo

r, fu

rniture

and a

ny

o

th

er

v

al

ua

bl

es

.

•

Be s

ur

e

to

p

er

fo

rm air t

ig

ht

ness test

by

press

ur

iz

in

g

w

ith

n

itr

og

en

g

as

after

c

om

plet

ed

refr

ig

eran

t p

ip

in

g

w

or

k.

If the density of refrigerant exceeds the limit in the event of refrigerant leakage in

the small room

, lack of oxygen can occu

r, which can cause serious accidents.

•

Do

no

t i

nstall

the

o

ut

do

or

u

nit

in

th

e

lo

cati

on

s list

ed

be

lo

w

.

•

L

oc

at

io

ns

w

he

re discha

rged ho

t a

ir or o

pe

ra

ting

so

und

of

th

e

ou

td

oo

r un

it

ca

n

bot

he

r n

eigh

bo

rh

oo

d.

•

L

oc

at

io

ns

w

he

re

ou

tle

t air

of

th

e

ou

td

oor un

it bl

ow

s dir

ect

ly

to

a

n

ani

m

al

or

pl

an

ts

. T

he

o

ut

le

t air

c

an

a

ffe

ct

a

dve

rsel

y

to

th

e

pl

an

t et

c.

•

L

oc

at

io

ns

w

he

re

vib

rat

ion

can b

e

amplified

and

tr

ansm

itt

ed due

to

insu

ffi

ci

en

t

st

re

ng

th

o

f s

tru

ct

ur

e.

•

L

oc

at

io

ns wh

er

e

vib

ra

tio

n

and op

er

at

io

n sound g

en

er

at

ed b

y

th

e ou

tdo

or

un

it

can

af

fe

ct

s

er

io

us

ly (

on

th

e w

all

o

r a

t t

he

pl

ace

ne

ar

bed

ro

om

).

•

L

oc

at

io

ns

w

he

re

an

e

quipme

nt

af

fe

ct

ed by high h

ar

m

onics is p

la

ce

d (TV s

et

o

r

ra

dio

re

ce

ive

r is p

la

ce

d

w

ithin

5

m

).

•

L

oc

at

io

ns

w

he

re

d

ra

in

ag

e

ca

nn

ot

run

of

f s

af

el

y.

It ca

n

af

fe

ct

sur

ro

undin

g

en

vir

on

m

en

t a

nd

c

aus

e

a

cl

ai

m

.

•

Do

no

t i

nstall

the

u

nit

ne

ar

th

e l

oc

ati

on

w

he

re

le

ak

ag

e

of

co

mb

ust

ib

le

gase

s

ca

n

oc

cu

r.

If

le

aked

g

ases accumu

la

te a

ro

und

the un

it,

it

c

an

c

aus

e

fir

e.

•

Do

n

ot install th

e

uni

t w

her

e

co

rr

osiv

e

gas (

su

ch as s

ulf

ur

ous

ac

id gas etc

.)

or

c

om

bu

stibl

e

gas (

su

ch as t

hi

nn

er a

nd

p

et

ro

le

um

g

ases)

ca

n accum

ula

te

or

c

olle

ct

, o

r w

here

v

olatile

co

m

bus

tib

le

su

bst

an

ces are h

an

dl

ed

.

Co

rr

os

ive

g

as

c

an

c

au

se

c

or

ro

si

on

o

f h

ea

t e

xc

ha

ng

er

, b

re

ak

ag

e

of

pl

as

tic

p

ar

ts

an

d

et

c.

A

nd

c

ombustible

ga

s

can ca

us

e

fir

e.

•

Do

no

t i

nstall

no

r u

se

the

syst

em

clo

se

to

the

equ

ipm

en

t t

hat

g

en

erat

es

el

ec

tr

oma

gn

et

ic

fi

el

ds

o

r h

ig

h f

req

uen

cy

h

arm

on

ic

s.

Equipme

nt

such

a

s i

nv

er

te

rs

, s

tand

by

ge

ne

ra

to

rs

, medical high

freque

ncy

equipme

nt

s and

te

le

communic

at

io

n

equip

m

en

ts can

aff

ec

t t

he

s

ys

te

m

, a

nd

c

au

se

m

al

fun

ct

io

ns

and b

re

akdo

wn

s.

The sy

ste

m can

also

af

fe

ct

m

edi

cal equipment a

nd

te

le

communic

at

io

n equipme

nt

, and

o

bs

tru

ct

it

s

fun

ct

io

n

or caus

e jammi

ng

.

•

Se

cur

e a

sp

ac

e f

or

in

stallat

ion

, i

ns

pec

tion

a

nd

m

ai

nt

en

an

ce

s

pe

cifi

ed

in

the

m

anu

al

.

In

su

ffi

ci

en

t sp

ac

e

can

re

su

lt in accide

nt

suc

h

as

pe

rsonal in

ju

ry

du

e

to

fallin

g

fro

m

th

e i

ns

ta

llat

io

n pl

ac

e.

•

Do

n

ot install

th

e

ou

td

oo

r u

nit in a

lo

ca

tio

n

w

he

re in

se

cts

an

d

sm

al

l

animals

ca

n

in

ha

bi

t.

Ins

ec

ts and small animal

s

can

en

te

r t

he

el

ec

tric

p

ar

ts

a

nd

c

ause

d

amag

e

or

fi

re

.

In

st

ru

ct

th

e us

er

to

k

ee

p

th

e

su

rrounding

s

cl

ea

n.

•

D

o

no

t u

se

th

e

ba

se

fr

am

e

fo

r o

ut

do

or

u

ni

t w

hi

ch

is

c

or

ro

de

d

or

d

am

ag

ed

du

e

to

lo

ng

p

er

io

ds

o

f o

pe

ra

tio

n.

Using a

n

old and da

m

age

ba

se

fr

ame ca

n

caus

e

the un

it

falling d

ow

n

an

d

cau

se

pe

rs

onal in

ju

ry

.

•

Do

n

ot

u

se

a

ny

m

aterial

s

ot

he

r t

ha

n a fus

e

w

ith

th

e

co

rr

ec

t r

at

in

g

in

th

e

lo

cat

io

n

w

he

re

fu

ses a

re

to

b

e u

se

d.

Con

ne

ct

ing

th

e

ci

rc

ui

t w

ith

co

pp

er

w

ire

o

r o

th

er

m

et

al

th

re

ad

c

an

c

ause un

it

fai

lu

re an

d

fir

e.

•

Do

n

ot

to

uc

h

an

y

bu

tt

ons

w

ith

w

et h

an

ds

.

It

ca

n

cau

se

el

ec

tric s

ho

cks

.

•

D

o

no

t t

ou

ch

a

ny

re

fr

ig

er

an

t p

ip

es

w

ith

y

ou

r h

an

ds

w

he

n

th

e system is

in

op

era

tio

n.

Du

ring op

er

at

ion

the

re

frige

rant pipes b

ec

ome

e

xtr

emely h

ot

or

e

xt

reme

ly

co

ld

de

pe

ndin

g

th

e

op

er

at

in

g

cond

iti

on

, a

nd

it

c

an

c

ause

bu

rn in

ju

ry

o

r fr

os

t in

ju

ry

.

•

Do

no

t t

ou

ch

th

e su

ct

io

n

or al

um

in

um fi

n

on

th

e

ou

td

oo

r u

ni

t.

This

m

ay

c

ause in

ju

ry

.

•

Do

n

ot

p

ut

a

nyth

in

g

on

th

e

ou

tdo

or

u

nit

a

nd

o

pe

ra

tin

g

un

it.

This

m

ay

c

ause

d

amage

the o

bj

ec

ts

or

in

ju

ry

du

e

to

falling to the o

bj

ect

.

•

Do

n

ot

u

se

th

e

unit

fo

r s

pe

cia

l p

ur

po

se

s

suc

h as

st

or

in

g

fo

od

s,

c

oo

lin

g

pr

ec

is

io

n

in

st

ru

m

en

ts

an

d

pr

es

er

vat

io

n

of

a

ni

m

al

s,

p

la

nt

s

or

a

rt

.

•

Do

n

ot

c

le

an

u

p

th

e

un

it

w

ith

w

at

er

.

•

Do

n

ot s

te

p

ont

o the

o

ut

do

or

u

ni

t.

•

W

he

n

th

e

ou

tdo

or

u

nit is

in

stal

le

d

on a

roo

f o

r a

h

ig

h

pla

ce

, p

ro

vi

de

pe

rma

ne

nt l

ad

de

rs

an

d

ha

nd

rails

al

on

g

th

e

ac

cess

rou

te and

fe

nc

es

ha

nd

rails

ar

ou

nd

th

e

ou

td

oo

r un

it.

Inverter

driven

split

P

AC

90,

100VNP

Designed

for

R32

refrigerant

a

)

b

)

c

)

d

)

e

)

f

)

g

)

h

)

Gauge manifold

Charge hose

Electronic scale for refrigerant charging

Torque wrench

Flare tool

Protrusion control copper pipe gauge

Vacuum pump adapter

Gas leak detector

Dedicated R32 tools

●

Do not use any refrigerant other than R32.

R32 will rise to pressure about 1.6 times higher than that of a conventional refrigerant (R22 or

R407C). A cylinder containing R32 has a lightblue indication mark on the top.

●

A unit designed for R32 has adopted a different size indoor unit operation valve charge port and a different size check joint p

rovided in the

unit to prevent the charging of a wrong refrigerant by mistake. The processed dimension of the flared part of a refrigerant pipe and a flare nut's parallel side measurement have also been alter

ed to raise

strength against pressure. Accordingly, you are required to arrange dedicated R32 tools listed in the table on the next page before installing or servicin

g this unit.

●

All indoor units must be models designed exclusively for R32. Check connectable indoor unit models in a catalog, etc. (A wrong

in door unit,

if connected into the system, will impair proper system operation)

Accessories for outdoor unit

• Model name and power source • Refrigerant piping length • Piping, wiring and miscellaneous small parts • Indoor unit installation manual

Grommet (Heat pump type only)

Drain elbow (Heat pump type only)

Reducer set ø9.52 ø6.35

2

1

1

1

2

3

Check before installation work

Q’ty

INS

TALL

ATION MAN

UAL FOR OUTDOOR UNIT

2. REFRIGERANT PIPING WORK

1)

Restrictions

on

unit

installation

and

use

●

Check

the

following

points

in

light

of

the

indoor

unit

specifications

and

the

installation

site.

●

Obse

rve

the

following

restrictions

on

unit

installation

and

use.

Improper

installation

can

result

in

a

compressor

failure

or

pe

rformance

degradation

.

2)

Determination

of

pipe

size

●

Determine

refrigerant

pipe

size

pursuant

to

the

following

guidelines

based

on

the

indoor

unit

specifications.

Gas pipe

Liquid pipe

ø15.88

ø6.35

Flare

Flare

ø15.88

ø6.35

ø15.88

ø9.52

1. HAULAGE AND INSTALLATION

(T

ake particular care in car

rying in or moving the unit, and always pe

rform such an operation with two or more persons.)

Intake

The

height

of

a

wall

is

1200mm

or

less.

(

se

rvice

space

)

Intake

Outlet

Fasten

with

bolts

(M10-12)

Use

a

thicker

block

to

anchor

deepe

r.

Use

a

long

block

to

extend

the

width.

CAUTION

When

a

unit

is

hoisted

with

slings

for

haulage,

take

into

consideration

the

offset

of

its

gravity

center

position.

If

not

properly

balanced,

the

unit

can

be

thrown

off-balance

and

fall.

1)

Delivery

●

Deliver

the

unit

as

close

as

possible

to

the

installation

site

before

removing

it

from

the

packaging.

●

When

you

have

to

unpack

the

unit

for

a

compelling

reason

before

you

haul

it

to

the

installation

point,

hoist

the

unit

with

nylon

slings

or

ropes

and

protection

pads

so

that

you

may

not

damage

the

unit.

2)

Portage

●

The

right

hand

side

of

the

unit

as

viewed

from

the

front

(diffuser

side)

is

heavie

r.

A

person

car

rying

the

right

hand

side

must

take

heed

of

this

fact.

A

person

car

rying

the

left

hand

side

must

hold

with

his

right

hand

the

handle

provided

on

the

front

panel

of

the

unit

and

with

his

left

hand

the

corner

column

section

.

5)

Installation

space

●

W

alls surrounding the unit in the four sides are not acceptable.

●

There must be a 1-meter or larger space in the above.

●

When more than one unit are installed side by side, provide a 250mm or wider interval between them as a service space. In order to facilitate servicing of controls, please provide a sufficient space between units so that their top plates can be removed easily.

●

Where a danger of short-ci

rcuiting exists, install guide louvers.

●

When more than one unit are installed, provide sufficient intake space consciously so that short-ci

rcuiting may not occur

.

●

Where

piling

snow

can

bu

ry

the

outdoor

unit,

provide

proper

snow

guards.

L

3

L

2

L

4

L

1

Example installation

Size

●

In installing the unit, fix the unit

’s legs with bolts specified on the above.

●

The protrusion of an anchor bolt on the front side must be kept within 15 mm.

●

Securely install the unit so that it does not fall over during earthquakes or strong winds, etc.

●

Refer to the above illustrations for information regarding concrete foundations.

●

Install the unit in a level area. (With a gradient of 5 mm or less.) Im

pr

op

er

in

st

al

la

tio

n

ca

n

re

su

lt

in

a

co

m

pr

es

so

rf

ai

lu

re

, b

ro

ke

n

pi

pi

ng

w

ith

in

th

e

un

it

an

d

ab

no

rm

al

n

oi

se

g

en

er

at

io

n.

6)

Installation

L

H

Outdoor unit

Indoor unit

CAUTION

●

Th

e

us

e

re

st

ric

tio

ns

ap

pe

ar

in

g

in

th

e

ta

bl

e

ab

ov

e

ar

e

ap

pl

ica

bl

e

to

th

e

st

an

da

rd

pi

pe

siz

e

co

m

bi

na

tio

ns

sh

ow

n

in

th

e

ta

bl

e

be

lo

w.

W

he

re

an

ex

ist

in

g

pi

pe

s

ys

te

m

is

u

til

ize

d,

di

ffe

re

nt

o

ne

-w

ay

pi

pe

le

ng

th

re

st

ric

tio

ns

sh

ou

ld

a

pp

ly

de

pe

nd

in

g

on

it

s

pi

pe

siz

e.

Fo

r m

or

e

in

fo

rm

at

io

n,

p

lea

se

se

e

“5

. U

TI

LI

ZA

TI

ON

OF

E

XI

ST

IN

G

PI

PI

NG

.”

Outdoor unit connected

Refrigerant piping (branch pipe

L)

Indoor unit connected

About brazing

When pipe is brazing.

(2)

If

the

unit

can

be

affected

by

strong

wind,

following

measures

are

required.

Strong

wind

can

cause

damage

of

fan

(fan

motor),

or

can

cause

pe

rformance

degradation,

or

can

trigger

anomalous

stop

of

the

unit

due

to

rising

of

high

pressure.

3)

Refrigerant

pipe

wall

thickness

and

material

●

Select

refrigerant

pipes

of

the

table

shown

on

the

right

wall

thickness

and

material

as

specified

for

each

pipe

size.

Pipe diameter [mm]

Minimum pipe wall thickness [mm]

Pipe material*

ø6.35

0.8

O-type pipe

ø15.88

1.0

O-type pipe

*Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS 77.150.30

NOTE

●

Select

pipes

having

a

wall

thickness

larger

than

the

specified

minimum

pipe

thickness.

He

avy

Pad

L1

L2

L3

L4

Open

300

100

250

Open

250

150

250

500

Open

100

250

(mm)

I

II

III

60

580

340

19

380

418

19

880

87.9

15

150

150

Intake

Outlet

①

Anchor bol tfixed position

②

Notabilia for installation

Plug the end of the pipe with tape, or other material, and fill the pipe with nitrogen gas.

Only use nitrogen gas (N

2

)

Taping

<

N

2

>

Nitrogen

Brazing

Station valve

Prima

ry side

Seconda

ry side

0.5MPa

Hand

Relief valve

Nitrogen

gas

Brazing

must

be

performed

under

a

nitrogen

gas

flo

w

.

Without

nitrogen

gas,

a

large

quantity

of

foreign

matters

(oxidized

film)

are

created,

causing

a

critical

failure

from

capilla

ry

tube

or

expansion

valve

clogging.

If the refrigerant is existing in the pipe at brazing, poisonous gas is produced.

Wind

direction

Wind

direction

Over

500

mm

2.Install the outlet air blow side of

the unit in a position perpendicular to the direction of wind.

3.

The

unit

should

be

installed

on

the

stable

and

level

foundation.

If

the

foundation

is

not

level,

the

down

the

unit

with

wires.

1.

Install the outlet air blow side of the unit to face a wall of building, or provide a fence or a windbreak screen.

7) To run the unit for a cooling operation,

when the outdoor temperature is –5°C or lower.

●

When the outdoor air temperature is –5°C or lower, provide a snow hood to the outdoor unit on site. So that strong wind will not blow against the outdoor heat exchanger directly.

4)

Caution

about

selection

of

installation

location

(1)

If

the

unit

is

installed

in

the

area

where

the

snow

will

accumulate,

following

measures

are

required.

The

bottom

plate

of

unit

and

intake,

outlet

may

be

blocked

by

sno

w

.

1

2

Provide

a

snow

hood

to

the

outdoor

unit

on

site.

3

Install

the

unit

under

eaves

or

provide

the

roof

on

site.

Since

drain

water

generated

by

defrost

control

may

freeze,

following

measures

are

required.

●

Don’t execute drain piping work

by using a drain elbow and drain grommets (accessories).

[Refer to DRAIN PIPING WORK.]

Install the unit on the base so that the bottom is higher than snow cover surface, and draining water is secured.

●

Attached heater on a base plate on site, if there is possibility to freeze drain water. In case that the product has a corrective drainage system, the drainage paths should have suitable threatment against freezing but be sure not to melt the material of drainage paths with heat.

30m

or less

20m

or less

20m

or less

L

H

H

Restrictions

Dimensional restrictions

Marks appearing in the drawing on the right

Main pipe length

Elevation difference between

Indoor unit

indoor and outdoor units

When the outdoor unit is positioned higher

FDT, FDE, FDU, FDUM, SRK

When the outdoor unit is positioned lower

3)

S

el

ec

tio

n

of

in

stalla

tio

n

lo

ca

tio

n

fo

r

th

e

ou

td

oo

r

un

it

Be

s

ur

e

to

sele

ct

a

s

ui

ta

ble

in

st

alla

tio

n

pla

ce

in

c

on

si

de

ra

tio

n

of

fo

llo

w

in

g

co

nd

iti

on

s.

〇

A

pla

ce

w

he

re

it

is

h

or

iz

on

ta

l,

st

ab

le

a

nd

c

an

e

nd

ur

e

th

e

un

it

w

ei

gh

t a

nd

wi

ll

no

t a

llo

w

v

ib

ra

tio

n

tr

an

sm

itt

an

ce

of

th

e

un

it.

〇

A

pla

ce

w

he

re

it

c

an

b

e

fr

ee

fr

om

p

os

si

bi

lit

y

of

b

ot

he

rin

g

ne

ig

hb

or

s

du

e

to

n

oi

se

o

r

ex

ha

us

t a

ir

fr

om

th

e

un

it.

〇

A

pla

ce

w

he

re

th

e

un

it

is

n

ot

e

xp

os

ed

to

o

il

sp

la

sh

es

.

〇

A

pla

ce

w

he

re

it

c

an

b

e

fr

ee

fr

om

d

an

ge

r

of

fl

am

m

ab

le

g

as

lea

ka

ge

.

〇

A

pla

ce

w

he

re

d

ra

in

w

at

er

c

an

b

e

di

sp

os

ed

w

ith

ou

t a

ny

tr

ou

bl

e.

〇

A

pla

ce

w

he

re

th

e

un

it

wil

l n

ot

b

e

af

fe

ct

ed

b

y

he

at

r

ad

ia

tio

n

fr

om

o

th

er

h

ea

t s

ou

rc

e.

〇

A

pla

ce

w

he

re

s

no

w

wil

l n

ot

a

cc

um

ul

at

e.

〇

A

pla

ce

w

he

re

th

e

un

it

ca

n

be

k

ep

t aw

ay

5

m

o

r

m

or

e

fr

om

T

V

se

t a

nd

/o

r

ra

di

o

recei

ve

r

in

o

rd

er

to

a

vo

id

a

ny

ra

di

o

or

T

V

in

te

rf

er

en

ce

.

〇

A

pla

ce

w

he

re

g

oo

d

ai

r

ci

rc

ula

tio

n

ca

n

be

s

ec

ur

ed

, a

nd

e

no

ug

h

se

rvi

ce

s

pa

ce

c

an

b

e

se

cu

re

d

fo

r

m

ai

nt

en

an

ce

an

d

se

rvic

e

of

th

e

un

it

sa

fe

ly

.

〇

A

pla

ce

w

he

re

th

e

un

it

wi

ll

no

t b

e

af

fect

ed

b

y

el

ec

tr

om

ag

net

ic

wav

es

a

nd

/o

r h

ig

h-

ha

rm

on

ic

wav

es

g

en

er

at

ed

b

y

ot

he

r

eq

ui

pm

en

t.

〇

A

pla

ce

w

he

re

c

hemic

al

s

ub

st

an

ce

s

lik

e

su

lfu

ric

g

as

, c

hl

or

ic

g

as

, a

ci

d

an

d

alka

li

(in

cl

ud

in

ga

m

m

on

ia

),

w

hi

ch

c

an

ha

rm

th

e

un

it,

wil

l n

ot

b

e

ge

ne

ra

te

d

an

d

no

t r

ema

in

.

〇

If

a

op

er

at

io

n

is

c

on

du

ct

ed

w

he

n

th

e

ou

td

oo

r

ai

r

te

m

pera

tu

re

is

-

5˚

C

lo

w

er

, t

he

o

ut

do

or

u

ni

t s

ho

ul

d

be

in

st

al

le

d

at

a

p

lace

w

he

re i

t i

s

no

t i

nfl

ue

nc

ed

b

y

na

tu

ral wi

nd

.

〇

A

pla

ce

w

he

re

s

tr

on

g

w

in

d wi

ll

no

t b

lo

w

a

ga

in

st

th

e

ou

tle

t a

ir

bl

ow

o

f t

he

u

ni

t.

D

o

no

t

in

st

al