-

123

-

'19 • PAC-SM-334

'09•SRK-DB-087D

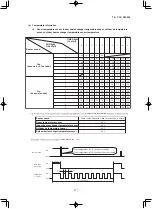

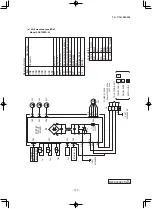

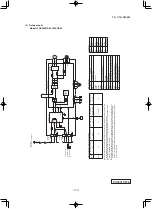

(9) Checking the indoor electrical equipment

(a) Indoor unit PCB check procedure

(b) Outdoor unit

Is there voltage between terminal

blocks

①

and

②

? (AC 220/230/240

V)

Indoor electrical components

are normal.

Is the voltage between terminal

blocks

②

and

③

oscillating between

DC 0 and 20V?

Inspect power source

for outdoor unit.

Replace fuse.

Replace indoor unit

PCB.

Is the fuse burnt out? (3.15 A)

NO

YES

YES

NO

YES

NO

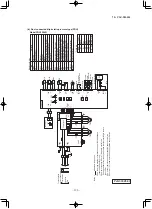

(b) Indoor fan motor check procedure

(i) Indoor unit PCB output check

① ④

⑤

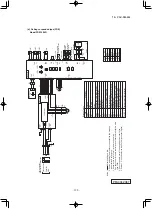

(ii) Fan motor resistance check

⑥

⑤

④

③

②

①

⑥

⑤

④

③

②

①

FM

i

DC15V

Indoor unit PCB

DC 308-336V

DC several V

(4-6 V)

CNU

(–)

GND

Blue

Yellow

White

Black

Red

Sensor

Operation

mode

Phenomenon

Shortcircuit

Disconnected wire

Heat exchanger

sensor

Cooling

Heating

Ourdoor air

temperature sensor

Cooling

Heating

Discharge pipe

sensor

All modes

Measuring point

Resistance when normal

① − ③

−

④ − ③

−

Measuring

point

Voltage range when

normal

① − ③

④ − ③

⑤ − ③

Defrosting is performed for 10 minutes at approx. 35 minutes.

Defrosting is performed for 10 minutes at approx. 35 minutes.

k

M

−

−

1)

2)

3)

This is a diagnostic procedure for determining if the indoor fan motor or the indoor unit PCB is broken down.

in the following figure are output for approximately 30 seconds, it means that the indoor unit PCB is normal and

the fan motor is broken down

the indoor unit PCB has

failed