-

153

-

⑦

Drain pipe (continued)

⑥

Refrigerant pipe

⑦

Drain pipe

Caution

●

Use the new refrigerant pipe.

When re-using the existing pipe system for R22 or R407C, pay attention to the following items.

・

Change the flare nuts with the attached ones (JIS category 2), and reprocess the flare parts.

・

Do not use thin-walled pipes.

●

Use phosphorus deoxidized copper alloy seamless pipe (C1220T specified in JIS H3300) for refrigeration pipe installation.

In addition, make sure there is no damage both inside and outside of the pipe, and no harmful

substances such as sulfur, oxide, dust or a contaminant stuck on the pipes.

●

Do not use any refrigerant other than R410A.

Using other refrigerant except R410A (R22 etc.) may degrade inside refrigeration oil. And air getting into

refrigeration circuit may cause over-pressure and resultant it may result in bursting, etc.

●

Store the copper pipes indoors and seal the both end of them until they are brazed in order to avoid any dust, dirt or

water getting into pipe. Otherwise it will cause degradation of refrigeration oil and compressor breakdown, etc.

●

Use special tools for R410 refrigerant.

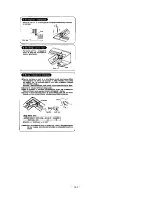

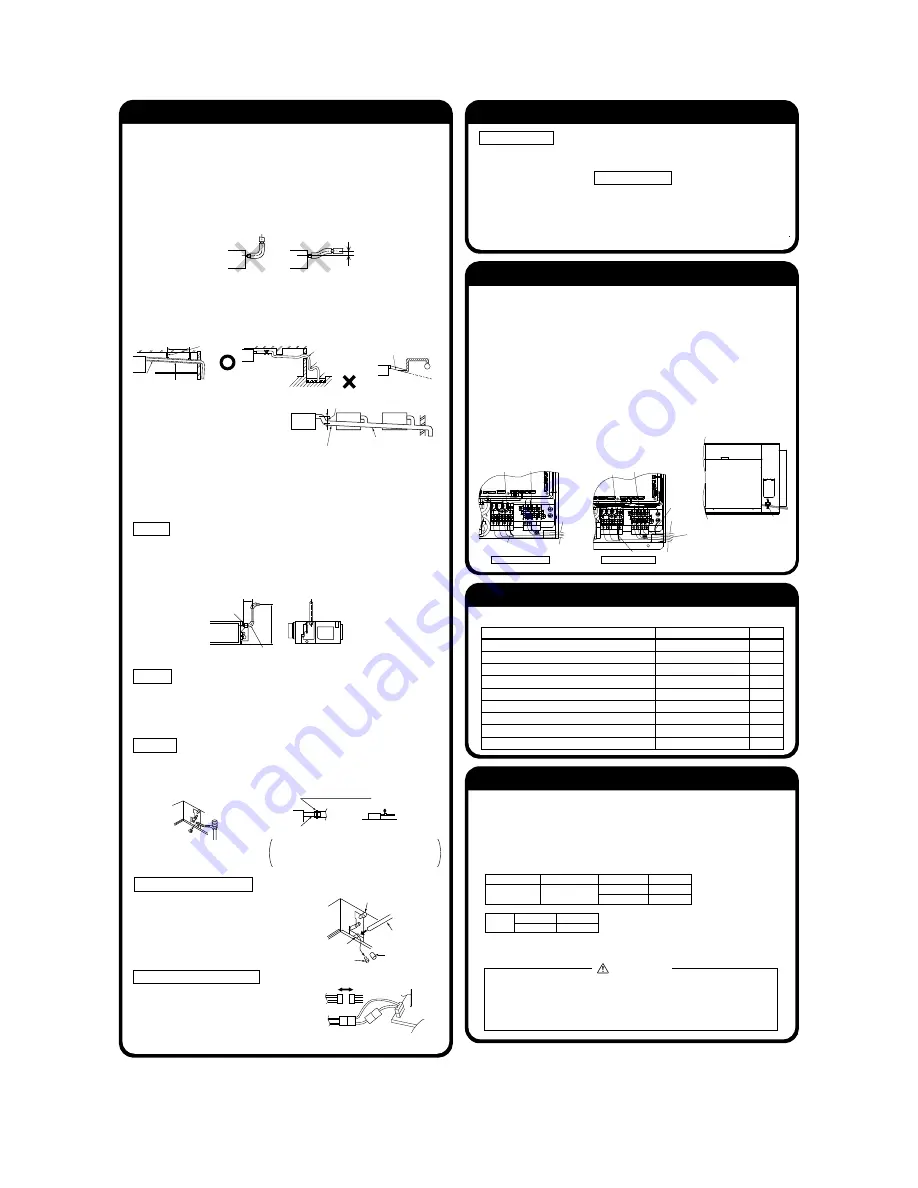

Piping work

When conducting piping work, make sure to allow the pipes

to be aligned in a straight line for at least 250 mm, as shown

in the left illustration. (This is necessary for the drain pump

to function)

Work procedure

1. Remove the flare nut and blind flanges on the pipe of the indoor unit.

※

Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving torque

to the nut with another spanner in order to avoid unexpected stress to the copper pipe, and then

remove them.

(Gas may come out at this time, but it is not abnormal.)

●

Pay attention whether the flare nut pops out. (as the indoor unit is sometimes pressured.)

2. Make a flare on liquid pipe and gas pipe, and connect the refrigeration pipes on the indoor unit.

※

Bend the pipe with as big radius as possible and do not bend the pipe repeatedly. In

addition, do not twist and crush the pipes.

※

Do a flare connection as follows:

●

Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving

torque to the nut with another spanner in order to avoid unexpected stress to the copper

pipe, and then remove them.

●

When fastening the flare nut, align the refrigeration pipe with the center of flare nut, screw

the nut for 3-4 times by hand and then tighten it by spanner with the specified torque

mentioned in the table below. Make sure to hold the pipe on the indoor unit securely by a

spanner when tightening the nut in order to avoid unexpected stress on the copper pipe.

3. Cover the flare connection part of the indoor unit with attached insulation material after a gas

leakage inspection, and tighten both ends with attached straps.

●

Make sure to insulate both gas pipes and liquid pipes completely.

※

Incomplete insulation may cause dew condensation or water dropping.

4. Refrigerant is charged in the outdoor unit.

As for the additional refrigerant charge for the indoor unit and piping, refer to the installation

manual attached to the outdoor unit.

Caution

●

Install the drain pipe according to the installation manual in order to drain properly.

Imperfection in draining may cause flood indoors and wetting the household goods

,

etc.

●

Do not put the drain pipe directly into the ditch where toxic gas such as sulfur, the other harmful and

inflammable gas is generated. Toxic gas would flow into the room and it would cause serious

damage to user’s health and safety (some poisoning or deficiency of oxygen). In addition, it may

cause corrosion of heat exchanger and bad smell.

●

Connect the pipe securely to avoid water leakage from the joint.

●

Insulate the pipe properly to avoid condensation drop.

●

Check if the water can flow out properly from both the drain outlet on the indoor unit and the end

of the drain pipe after installation.

●

Make sure to make descending slope of greater than 1/100 and do not make up-down bend and/or trap

in the midway. In addition, do not put air vent on the drain pipe. Check if water is drained out properly

from the pipe during commissioning. Also, keep sufficient space for inspection and maintenance.

Work procedure

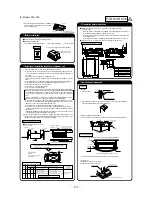

1. Insert the supplied drain hose (the end made of soft PVC) to the step of the drain socket on the indoor unit

and fix it securely with the clamp.

Attach the hose clamp to the drain hose around 10mm from the end.

●

Do not apply adhesives on this end.

●

Do not use acetone-based adhesives

to connect to the drain socket.

Pipe diameter

Tightening torque N·m

φ

6.35

φ

9.52

φ

12.7

φ

15.88

φ

19.05

14 to 18

34 to 42

49 to 61

68 to 82

100 to 120

Strap (Accessory)

Pipe cover (Accessory)

The thickness of insulation should be 20mm or more.

2. Prepare a joint for connecting VP-20 pipe, adhere and connect the joint to the drain hose

(the end made of rigid PVC), and adhere and connect VP-20 pipe (prepare on site).

※

As for drain pipe, apply VP-20 made of rigid PVC which is on the market.

●

When installing drain pipe, use VP-20 for the pipe goes up the closest to the unit, and

VP-25 or higher number product for farther pipes.

●

Make sure that the adhesive will not get into the supplied drain hose.

It may cause the flexible part broken after the adhesive is dried up and gets rigid.

●

The flexible drain hose is intended to absorb a small difference at installation of the unit

or drain pipes. Intentional bending, expanding may cause the flexible hose broken and

water leakage.

3. Make sure to make descending slope of greater than 1/100 and do not make up-down bend

and/or trap in the midway.

●

Pay attention not to give stress on the pipe on the indoor unit side, and support and fix

the pipe as close place to the unit as possible when connecting the drain pipe.

●

Do not set up air vent.

●

When sharing a drain pipe for more than

one unit, lay the main pipe 100mm

below the drain outlet of the unit. In

addition, select VP-30 or bigger size for

main drain pipe.

⑦

Drain pipe (continued)

⑩

Tap selection on blower unit (when the high peformance filter is used)

⑧

Wiring-out position and wiring connection

⑨

Check list after installation

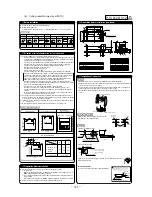

Drain pump operation

○

In case electrical wiring work finished

Drain pump can be operated by remote controller (wired).

For the operation method, refer to Operation for drain pump in the installation manual for wiring

work.

○

In case electrical wiring work not finished

Drain pump will run continuously when the dip switch“SW7-1” on the indoor unit PCB is turned ON, the Connec-

tor CNB is disconnected, and then the power supply (230VAC on the terminal block

①

and

②

) is turned ON.

Make sure to turn OFF “SW7-1” and reconnect the Connector CNB after the test.

●

Electrical installation work must be performed according to the installation manual by an

electrical installation service provider qualified by a power provider of the country, and be

executed according to the technical standards and other regulations applicable to electrical

installation in the country.

Be sure to use an exclusive circuit.

●

Use specified cord, fasten the wiring to the terminal securely, and hold the cord securely in

order not to apply unexpected stress on the terminal.

●

Do not put both power source line and signal line on the same route. It may cause miscommu-

nication and malfunction.

●

Be sure to do D type earth work.

●

For the details of electrical wiring work, see attached instruction manual for electrical wiring

work.

1. Remove a lid of the control box (2 screws).

2. Hold each wiring inside the unit and fasten them to terminal block securely.

3. Fix the wiring with clamps.

4. Install the removed parts back to original place.

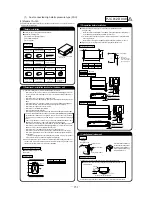

The fan tap’s factory setting is “Standard.” If you want to change it to the high static-pressure setting,

you can avail yourself of the following two methods. Use one of the two methods to set the fan tap.

Make sure to perform the functional setting with remote controller.

Select [Indoor function] in the functional setting mode, and change the function number [01]

[High wall setting].

For operation method, refer to the user’s manual of the remote controller.

⑤

Duck Work

A corrugated board (for preventing sputtering) is attached to the main body of the air conditioner

(on the outlet port). Do not remove it until connecting the duct.

①●

The air conditioner main unit does not have an air filter. Incorporate it into the easy-to-clean

suction grille.

②

Blowout duct

●

The ducts should be at their minimum lengths.

●

Keep the bends to a minimum. (The bending radius should be as large as possible.)

●

Conduct the duct work before ceiling attachment.

③

Suction duct

●

Make sure to insulate the duct to prevent dewing on it.

④

Location and form of blow outlet should be selected so that air from the outlet will be distrib-

uted all over the room, and equipped with a device to control air volume.

⑤

Make sure provide an inspection hole on the ceiling. It is indispensable to service elecric

equipment, motor, functional components and cleaning of heat exchanger.

①

If a duct is not provided at the suction side but it is substituted with the space over the ceiling,

humidity in the space will increase by the influence of capacity of ventilation fan, strength of

wind blowing against the out door air louver, weather (rainy day) and others.

a)Moisture in air is likely to condense over the external plates of the unit and to drip on the

ceiling. Unit should be operated under the conditions as listed in the above table and within

the limitation of wind volume. When the building is a concrete structure, especially immedi-

ately after the construction, humidity tends to rise even if the space over the ceiling is not

substituted in place of a duct. In such occasion, it is necessary to insulate the entire unit with

glass wool (25mm). (Use a wire net or equivalent to hold the glass wool in place.)

b)It may run out the allowable limit of unit operation (Example: When outdoor air temperature

is 35°C DB, suction air temperature is 27°C WB) and it could result in such troubles as

compressor overload, etc..

c)There is a possibility that the blow air volume may exceed the allowable range of operation

due to the capacity of ventilation fan or strength of wind blowing against external air louver

so that drainage from be heat exchanger may fall to reach the drain pan but leak outside

(Example: drip on to the ceiling) with consequential water leakage in the room.

②

If vibration damping is not conducted between the unit and the duct, and between the unit and

the slab, vibration will be transmitted to the duct and vibration noise may occur. Also, vibration

may be transmitted from the unit to the slab. Vibration damping must be performed.

P.C. board

Fuse

For drain motor

connector CNR (blue)

Function number A Functional content B Setting content C Default setting

01

High wall setting

Standard

○

High wall 1

Static

Pressure

Standard Tap

50

High Tap

130

UNIT: Pa

CAUTION

●

Taps should not be used under static pressure outside the unit mentioned above.

Dew condensation may occur with the unit and wet the ceiling or furniture.

●

Do not use under static pressure outside the unit of 50Pa or less. Water drops may be

blown from the diffuser outlet of the unit and wet the ceiling or furniture.

Air conditioner main unit

Ceiling suriace

Suction grille

(Locality)

Suction grille

(option)

Suction hole

(marketed item)

(with air filter)

Inspection hole

Suction duct

(marketed item)

Blow outlet

Blowout duct

(optional or marketed item)

Bad example of duct work

For ventilation

Louver to

outdoor air

Refrigerant pipe

250mm

(Section where attached

in a straight line)

Drain socket

Drain hose

Stage difflernce part

Insert water supply hose

for 50mm to

supply water.

(Insert hose facing

toward bottom.)

Attached drain hose clamp

Drain

piping

Main

unit

Drain situation can be checked with transparent socket.

If the electrical work has not been completed, connect a convex

joint in the drain pipe connection to provide a water inlet.

Then, check if water leaks from the piping system and that

drain flows through the drain pipe normally.

Pour water into a convex joint

Remove grommet

Make sure to Install

it back after test.

Connecting port of top drain pipe

Insulating material

Rubber stopper (to be removed)

Connecting port of bottom drain pipes

Standard hard polyvinyl

chloride pipes

Bad example of duct work

(

)

●

Check the following items after all installation work completed.

Check if

Expected trouble

Check

The indoor and outdoor units are fixed securely?

Falling, vibration, noise

Inspection for leakage is done?

Insufficient capacity

Insulation work is properly done?

Water leakage

Water is drained properly?

Water leakage

Supply voltage is same as mentioned in the model name plate?

PCB burnt out, not working at all

There is mis-wiring or mis-connection of piping?

PCB burnt out, not working at all

Earth wiring is connected properly?

Electric shock

Cable size comply with specified size?

PCB burnt out, not working at all

Any obstacle blocks airflow on air inlet and outlet?

Insufficient capacity

Descending slope greater than 1/100

As wide as possible

(about100mm)

Insulation material

Supporting metal

Descending slope greater than 1/100

Air vent

No bump

No trap

Not touching the water

Trapped air will

generate noises.

VP-30 or bigger

1.5m~2m

Single unit wiring connection

Inner/outer

connecting line

Remote

controller line

Power source side

terminal block

Signal side

terminal block

CNS

CNV

CNT2

CNN

CNN

CNH

CNH

CNZ

CNA

CND

CNK2

CNR2

Multi unit wiring connection

Superlynk line

(Shielded cord)

Earth

(Shielded cord)

Inner/outer

connecting line

Signal side

terminal block

Power source side

terminal block

Remote

controller line

CNS

CNV

CNT2

CNN

CNH

CNZ

CNA

CND

CNK2

CNK1

CNR2

Bottom

Top

Control box

Power source

line clamp

Bad example

Bad example

Good example

Earth

Earth

Pipe cover (small)

(For insulation) (Accessory)

Pipe cover (For insulation)

(Prepare on site)

Unit

Pipe cover (big)

(For insulation) (Accessory)

VP-20

(Prepare on site)

Joint for VP-20

(Prepare on site)

VP-25

(Prepare on site)

Drain hose

(Accessory)

Drain socket Clamp (Accessory)

(No adhesive allowed)

Fasten the screw securely

Hose clamp

Drain hose

Drain socket

Metal plate

10mm

290~325mm

Drain hose

600

Maximum local drain up dimension

Joint for VP20 (local procurement)

Right overhead

4. Insulate the drain pipe.

●

Be sure to insulate the drain socket and rigid PVC pipe installed indoors otherwise it may

cause dew condensation and water leakage.

※

After drainage test implementation, cover the drain socket part with pipe cover (small size), then

use the pipe cover (big size) to cover the pipe cover (small size), clamps and part of the drain

hose, and fix and wrap it with tapes to wrap and make joint part gapless.

Drain up

●

The position for drain pipe outlet can be raised up to 600mm above the ceiling. Use elbows for

installation to avoid obstacles inside ceiling. If the horizontal drain pipe is too long before vertical pipe,

the backflow of water will increase when the unit is stopped, and it may cause overflow of water from

the drain pan on the indoor unit. In order to avoid overflow, keep the horizontal pipe length and offset of

the pipe within the limit shown in the figure below.

Otherwise, the construction point makes it same as drain pipe construction.

Drain test

1. Conduct a drain test after completion of the electrical work.

2. During the trail, make sure that drain flows properly through the piping and that no water

leaks from connections.

3. In case of a new building, conduct the test before it is furnished with the ceiling.

4. Be sure to conduct this test even when the unit is installed in the heating season.

Procedures

1. Supply about 1000 cc of water to the unit through the air outlet by using a feed water pump.

2. Check the drain while cooling operation.

Outline of bottom drain piping work

●

If the bottom drain piping can be done with a

descending gradient (1/50-1/100), it is possible to

connect the pipes as shown in the drawing below.

Uncoupling the drain motor connector

●

Uncouple the connector CNR for the drain motor

as illustrated in the drawing on the right.

Note: If the unit is run with the connector coupled,

drain water will be discharged from the upper drain

pipe joint, causing a water leak.

Over 20mm

Summary of Contents for FDE112KXE6A

Page 104: ... 102 ...

Page 111: ... 108 b Ceiling cassette 4 way Compact type FDTC Models All moddels B PJA003Z331 ...

Page 112: ... 109 c Ceiling cassette 2 way type FDTW Models FDTW28KXE6 45KXE6 56KXE6 B PJB001Z560 ...

Page 113: ... 110 Models FDTW71KXE6 90KXE6 B PJB001Z561 ...

Page 114: ... 111 Models FDTW112KXE6 140KXE6 B PJB001Z562 ...

Page 115: ... 112 d Ceiling cassette 1 way type FDTS Model FDTS45KXE6 A PJC001Z195 ...

Page 116: ... 113 Model FDTS71KXE6 A PJC001Z196 ...

Page 117: ... 114 e Ceiling cassette 1 way compact type FDTQ Models All models A PJC001Z190 ...

Page 118: ... 115 Models All models Duct panel A PJC001Z240 ...

Page 121: ... 118 Models FDU224KXE6 280KXE6 B PJD001Z230 ...

Page 123: ... 120 Models FDUM112KXE6 140KXE6 B PJR002Z259 ...

Page 124: ... 121 h Duct connected Ultra thin Low static pressure type FDQS Models All models C PJC001Z200 ...

Page 125: ... 122 i Wall mounted type FDK Models FDK22KXE6 28KXE6 36KXE6 45KXE6 56KXE6 B PHA000Z983 ...

Page 126: ... 123 Models FDK71KXE6 B PHA000Z984 ...

Page 127: ... 124 j Ceiling suspended type FDE Models FDE36KXE6A 45KXE6A 56KXE6A B PFA003Z826 ...

Page 128: ... 125 Models FDE71KXE6A 112KXE6A 140KXE6A B PFA003Z827 ...

Page 129: ... 126 k Floor standing with casing type FDFL Models All models B PGD000Z053 ...

Page 130: ... 127 l Floor standing without casing type FDFU Models All models A PGD000Z058 ...

Page 131: ... 128 m Duct Connected Compact and Flexible type FDUH Models All models A PJC001Z255 ...

Page 138: ... 135 ...

Page 139: ... 136 ...

Page 143: ... 140 b ...

Page 144: ... 141 ...

Page 191: ... 188 5 4 Installation of outdoor unit ...

Page 193: ... 190 ...

Page 194: ... 191 ...

Page 195: ... 192 ...

Page 196: ... 193 ...

Page 197: ... 194 ...

Page 198: ... 195 ...

Page 199: ... 196 ...

Page 200: ... 197 ...

Page 201: ... 198 ...

Page 202: ... 199 ...

Page 203: ... 200 ...

Page 204: ... 201 ...

Page 205: ... 202 ...

Page 206: ... 203 ...

Page 207: ... 204 ...

Page 208: ... 205 ...

Page 210: ... 207 ...

Page 211: ... 208 ...

Page 212: ... 209 ...

Page 215: ... 212 2 model type DIS model type HEAD ...

Page 216: ... 213 2 2 ...

Page 217: ... 214 2 2 2 2 2 ...