-

163

-

(i)

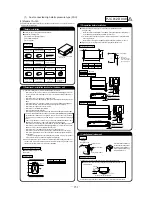

Wallmounted type (FDK)

PHA012D033

①

Before installation

②

Selection of installation location for the indoor unit

Installation-related items

Mounting plate

Tapping screw

Insulation

Strap

1

10

1

4

Attached to the backside of the indoor unit.

For heat insulation, 50mm x 160mm

For wire clamp

For the mounting plate,

4mm (dia.) x 25mm (length)

Space for installation and service

UNIT: mm

INSTALLATION MANUAL FOR WALL-MOUNTED UNIT (FDK)

This manual is for the installation of an indoor unit.

For electrical wiring work (Indoor), refer to the electrical wiring work installation manual. For remote

controller installation, refer to the installation manual attached to a remote controller. For wireless kit

installation, refer to the installation manual attached to a wireless kit. For electrical wiring work

(Outdoor) and refrigerant pipe work installation for outdoor unit, refer to the installation manual

attached to an outdoor unit.

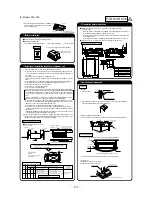

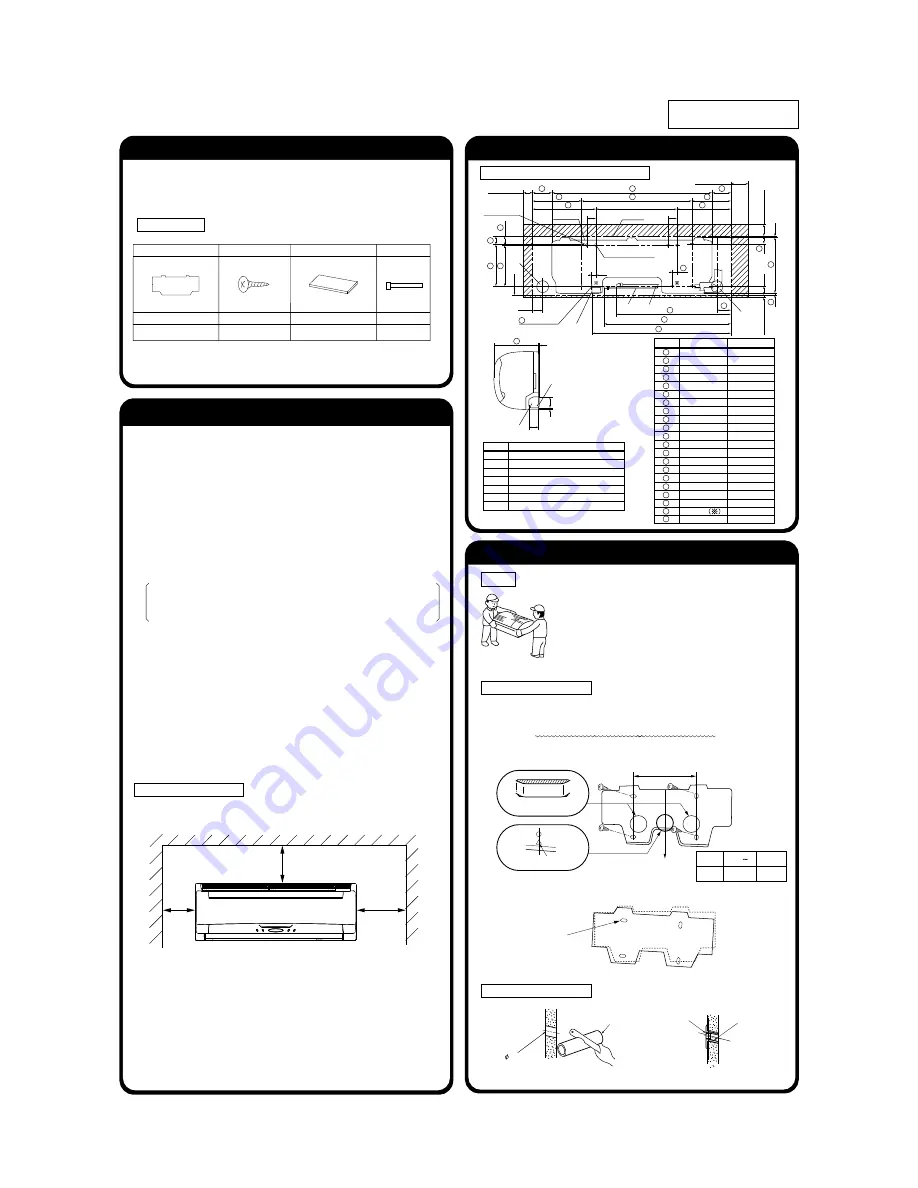

④

Installation of indoor unit

PHA012D033

Ov

er 65

Over 50

Over 100

ATTENTION

●

Secure a working space for inspection and maintenance.

Datum hole

ATTENTION

●

This unit cannot be installed directly onto a wall surface. Regardless of the surface it is to be

installed onto, you should use the mounting plate supplied with the unit.

○

Install it securely by spotting a structural member running underneath the wall (stud or the

like) and after ascertaining its levelness.

○

The levelness of the mounting plate should be adjusted with the four fixing screws fastened

temporarily.

○

Rotate the plate around the datum hole to achieve the levelness.

Installation of the mounting plate

Hints for making a hole on a wall

Haulage

○

Give a descending grade of 5

°

from the interior to the exterior.

Level positioning mark

Level guide (2 places)

B

Wall

Sleeve

Sealing plate

Indoor

65

mm

Outdoor

Wall

Sleeve

Type 22 56

450

Type 71

450,610

UNIT: mm

Model

B Size

ATTENTION

●

In carrying the unit into an installation site, carry it in the original

packaging to a point as close to the proposed installation site as

possible.

●

When the unit needs to be unpacked during haulage due to a

compelling reason, wrap it with nylon slings or the like to prevent

possible damages.

Note: Do not hold the unit by the diffuser louver in carrying it.

●

When the unit needs to be laid on a floor after unpacking, always lay

it with its front facing upward.

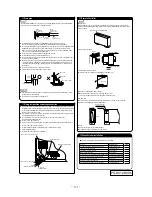

③

Preparation before installation

Service space

50

50

50

25

53.5

450

Service space

100

Ser

vice space

Ser

vice space

44.5

44.5

65

8.5

4-12x18 oval hole

-5x17.5 oval hole

A

C

B

E

D

Installing plate

Indoor unit

Hole for public corporation

3

1

5

7

3

9

10

11

12

21

20

19

6

8

4

18

16

17

15

14

2

13

60

9

55

3

F

G

Front view for installing position and installing space

●

Read the “SAFETY PRECAUTIONS” carefully first of all and then strictly follow it during the installation work

in order to protect yourself.

●

The precautionary items mentioned below are distinguished into two levels, and

.

: Wrong installation would cause serious consequences such as injuries or death.

: Wrong installation might cause serious consequences depending on circumstances.

Both mentions the important items to protect your health and safety so strictly follow them by any means.

●

After completing the installation, do commissioning to confirm there are no abnormalities, and explain to the

customers about “SAFETY PRECAUTIONS”, correct operation method and maintenance method (air filter

cleaning, operation method and temperature setting method) with user’s manual of this unit.

Ask your customers to keep this installation manual together with the user’s manual. Also, ask them to hand

over the user’s manual to the new user when the owner is changed.

CAUTION

CAUTION

●

Installation should be performed by the specialist.

If you install the unit by yourself, it may lead to serious trouble such as water leakage, electric shock, fire, and injury due to overturn

of the unit.

●

Install the system correctly according to these installation manuals.

Improper installation may cause explosion, injury, water leakage, electric shock, and fire.

●

Consider measurement not to exceed the limit of the density of refrigerant in the event of leakage especially

when it is installed in a small room.

Consult the specialist about the measure. If the density of refrigerant exceeds the limit in the event of the leakage, serious accidents

may occur due to lack of oxygen.

●

Use the genuine accessories and the specified parts for installation.

If parts unspecified by our company are used it could cause water leakage, electric shock, fire, and injury due to overturn of the unit.

●

Ventilate the working area well in case the refrigerant leaks during installation.

If the refrigerant contacts the fire, toxic gas is produced.

●

Install the unit in a location that can hold heavy weight.

Improper installation may cause the unit to fall leading to accidents.

●

Install the unit properly in order to be able to withstand strong winds such as typhoons, and earthquakes.

Improper installation may cause the unit to fall leading to accidents.

●

Do not mix air in to the cooling cycle on installation or removal of the air conditioner.

If air is mixed in, the pressure in the cooling cycle will rise abnormally and may cause explosion and injuries.

●

Be sure to have the electrical wiring work done by qualified electrical installer, and use exclusive circuit.

Power source with insufficient capacity and improper work can cause electric shock and fire.

●

Use specified wire for electrical wiring, fasten the wiring to the terminal securely, and hold the cable securely in

order not to apply unexpected stress on the terminal.

Loose connections or hold could result in abnormal heat generation or fire.

●

Arrange the electrical wires in the control box properly to prevent them from rising. Fit the lid of the services

panel property.

Improper fitting may cause abnormal heat and fire.

●

Check for refrigerant gas leakage after installation is completed.

If the refrigerant gas leaks into the house and comes in contact with a fan heater, a stove, or an oven, toxic gas is produced.

●

Use the specified pipe, flare nut, and tools for R410A.

Using existing parts (R22) could cause the unit failure and serious accident due to explosion of the cooling cycle.

●

Tighten the flare nut according to the specified method by with torque wrench.

If the flare nut were tightened with excess torque, it could cause burst and refrigerant leakage after a long period.

●

Make sure there is no dust or clogging on both the plug and the socket nor loose connection of the socket

before plugging, and plug in securely to the end of the blade.

Accumulation of dust, clogging on the socket or plug, or loose installation of the socket could cause electric shock and fire. Replace

the socket if it is loose.

●

Connect the pipes for refrigeration circuit securely in installation work before compressor is operated.

If the compressor is operated when the service valve is open without connecting the pipe, it could cause explosion and injuries due

to abnormal high pressure in the system.

●

Stop the compressor before removing the pipe on pump down work.

If the pipe is removed when the compressor is in operation with the service valve open, air would be mixed in the refrigeration circuit

and it could cause explosion and injuries due to abnormal high pressure in the cooling cycle.

●

Use the genuine optional parts. And installation should be performed by a specialist.

If you install the unit by yourself, it could cause water leakage, electric shock and fire.

●

Do not repair by yourself. And consult with the dealer about repair.

Improper repair may cause water leakage, electric shock or fire.

●

Consult the dealer or a specialist about removal of the air conditioner.

Improper installation may cause water leakage, electric shock or fire.

●

Turn off the power source during servicing or inspection work.

If the power is supplied during servicing or inspection work, it could cause electric shock and injury by the operating fan.

●

Do not run the unit when the panel or protection guard are taken off.

Touching the rotating equipment, hot surface, or high voltage section could cause an injury to be caught in the machine, to get

burned, or electric shock.

●

Shut off the power before electrical wiring work.

It could cause electric shock, unit failure and improper running.

●

Perform earth wiring surely.

Do not connect the earth wiring to the gas pipe, water pipe, lightning rod and telephone earth wiring. Improper earth could

cause unit failure and electric shock due to a short circuit.

●

Use the circuit breaker of correct capacity.

Using the incorrect capacity one could cause the system failure and fire.

●

Do not use any materials other than a fuse of correct capacity where a fuse should be used.

Connecting the circuit by wire or copper wire could cause unit failure and fire.

●

Do not install the indoor unit near the location where there is possibility of flammable gas leakages.

If the gas leaks and gathers around the unit, it could cause fire.

●

Do not install and use the unit where corrosive gas (such as sulfurous acid gas etc.) or flammable gas

(such as thinner, petroleum etc.) may be generated or accumulated, or volatile flammable substances

are handled.

It could cause the corrosion of heat exchanger, breakage of plastic parts etc. And inflammable gas could cause fire.

●

Do not use the indoor unit at the place where water splashes such as laundry.

Indoor unit is not waterproof. It could cause electric shock and fire.

●

Do not use the indoor unit for a special purpose such as food storage, cooling for precision

instrument, preservation of animals, plants, and a work of art.

It could cause the damage of the items.

●

Do not install nor use the system near equipments which generate electromagnetic wave or high

harmonics.

Equipments like inverter equipment, private power generator, high-frequency medical equipment, or telecommunication

equipment might influence the air conditioner and cause a malfunction and breakdown. Or the air conditioner might

influence medical equipments or telecommunication equipments, and obstruct their medical activity or cause jamming.

●

Do not install the remote controller at the direct sunlight.

It could cause breakdown or deformation of the remote controller.

●

Do not install the indoor unit at the place listed below.

· Places where flammable gas could leak.

· Places where carbon fiber, metal powder or any powder is floated.

· Place where the substances which affect the air conditioner are generated such as sulfide gas, chloride gas, acid or

alkali.

· Places exposed to oil mist or steam directly.

· On vehicles and ships

· Places where machinery which generates high harmonics is used.

· Places where cosmetics or special sprays are frequently used.

· Highly salted area such as beach.

· Heavy snow area

· Places where the system is affected by smoke from a chimney.

· Altitude over 1000m

●

Do not put any valuables which will break down by getting wet under the air conditioner.

Condensation could drop when the relative humidity is higher than 80% or drain pipe is clogged, and it damages user’s

belongings.

●

Do not use the base frame for the outdoor unit which is corroded or damaged after a long period of

use.

It could cause the unit falling down and injury.

●

Pay attention not to damage the drain pan by weld sputter when brazing work is done near the unit.

If sputter entered into the unit during brazing work, it could cause damage (pinhole) of drain pan and leakage of water. To

avoid damaging, keep the indoor unit packed or cover the indoor unit.

●

Install the drain pipe to drain the water surely according to the installation manual.

Improper connection of the drain pipe may cause dropping water into room and damaging user’s belongings.

●

Do not put the drain pipe directly into the ditch where toxic gas such as sulfide gas is generated.

Toxic gas would flow into the room and it would cause serious damage to user’s health and safety.

●

Do not share the drain pipe for indoor unit and GHP (Gas Heat Pump system) outdoor unit.

Toxic exhaust gas would flow into room and it might cause serious damage (some poisoning or deficiency of oxygen) to

user’s health and safety.

●

For drain pipe installation, be sure to make descending slope of greater than 1/100, not to make traps,

and not to make air-bleeding.

Check if the drainage is correctly done during commissioning and ensure the space for inspection and maintenance.

●

Ensure the insulation on the pipes for refrigeration circuit so as not to condense water.

Incomplete insulation could cause condensation and it would wet ceiling, floor, and any other valuables.

●

Do not install the outdoor unit where is likely to be a nest for insects and small animals.

Insects and small animals could come into the electronic components and cause breakdown and fire. Instruct the user to

keep the surroundings clean.

●

Pay extra attention, carrying the unit by hand.

Carry the unit with 2 people if it is heavier than 20kg. Do not use the plastic straps but the grabbing place, moving the unit

by hand. Use protective gloves in order to avoid injury by the aluminum fin.

●

Make sure to dispose of the packaging material.

Leaving the materials may cause injury as metals like nail and woods are used in the package.

●

Do not operate the system without the air filter.

It may cause the breakdown of the system due to clogging of the heat exchanger.

●

Do not touch any button with wet hands

It could cause electric shock.

●

Do not touch the refrigerant piping with bare hands when in operation.

The pipe during operation would become very hot or cold according to the operating condition, and it could cause a burn

or frostbite.

●

Do not clean up the air conditioner with water.

It could cause electric shock.

●

Do not turn off the power source immediately after stopping the operation.

Be sure to wait for more than 5 minutes. Otherwise it could cause water leakage or breakdown.

●

Do not control the operation with the circuit breaker.

It could cause fire or water leakage. In addition, the fan may start operation unexpectedly and it may cause injury.

WARNING

CAUTION

①

Select the suitable areas to install the unit under approval of the user.

・

Areas where the indoor unit can deliver hot and cold wind sufficiently. Suggest to the user

to use a circulator if the ceiling height is over 3m to avoid warm air being accumulated on

the ceiling.

・

Areas where there is enough space to install and service.

・

Areas where it can be drained properly. Areas where drain pipe descending slope can be

taken.

・

Areas where there is no obstruction of airflow on both air return grille and air supply port.

・

Areas where fire alarm will not be accidentally activated by the air conditioner.

・

Areas where the supply air does not short-circuit.

・

Areas where it is not influenced by draft air.

・

Areas not exposed to direct sunlight.

・

Areas where dew point is lower than around 23°C and relative humidity is lower than 80%.

This indoor unit is tested under the condition of JIS (Japan Industrial Standard) high humid-

ity condition and confirmed there is no problem. However, there is some risk of condensa-

tion drop if the air conditioner is operated under the severer condition than mentioned

above.

・

Areas where TV and radio stays away more than 1m. (It could cause jamming and noise.)

・

Areas where any items which will be damaged by getting wet are not placed such as food,

table wares, server, or medical equipment under the unit.

・

Areas where there is no influence by the heat which cookware generates.

・

Areas where not exposed to oil mist, powder and/or steam directly such as above fryer.

・

Areas where lighting device such as fluorescent light or incandescent light doesn’t affect the

operation.

(A beam from lighting device sometimes affects the infrared receiver for the wireless remote

controller and the air conditioner might not work properly.)

②

Check if the place where the air conditioner is installed can hold the weight of the unit. If it is

not able to hold, reinforce the structure with boards and beams strong enough to hold it. If the

strength is not enough, it could cause injury due to unit falling.

SAFETY PRECAUTIONS

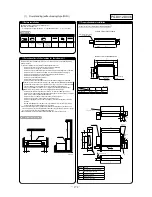

UNIT: mm

●

Install correctly according to the installation manual.

●

Confirm the following points:

○

Unit type/Power supply specification

○

Pipes/Wires/Small parts

○

Accessory items

Symbol

A

B

C

D

E

F

G

Gas piping

Liquid piping

Wall pulling hole for right rear piping

Wall pulling hole for left rear piping

Drain piping

Outlet for wiring

Outlet for piping

Symbol

Type 22 - 56

Type 71

693

284.2

73.5

-

-

-

207.5

182.5

63.5

533.5

603.5

515

5.3

-

220.5

47.5

-

-

886

301.8

106

610

269

219

349

299

77

633.5

703.5

772

7.7

43

221.5

49.5

259

248

225

46

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

0

25

19

2

6

20

21

18

Summary of Contents for FDE112KXE6A

Page 104: ... 102 ...

Page 111: ... 108 b Ceiling cassette 4 way Compact type FDTC Models All moddels B PJA003Z331 ...

Page 112: ... 109 c Ceiling cassette 2 way type FDTW Models FDTW28KXE6 45KXE6 56KXE6 B PJB001Z560 ...

Page 113: ... 110 Models FDTW71KXE6 90KXE6 B PJB001Z561 ...

Page 114: ... 111 Models FDTW112KXE6 140KXE6 B PJB001Z562 ...

Page 115: ... 112 d Ceiling cassette 1 way type FDTS Model FDTS45KXE6 A PJC001Z195 ...

Page 116: ... 113 Model FDTS71KXE6 A PJC001Z196 ...

Page 117: ... 114 e Ceiling cassette 1 way compact type FDTQ Models All models A PJC001Z190 ...

Page 118: ... 115 Models All models Duct panel A PJC001Z240 ...

Page 121: ... 118 Models FDU224KXE6 280KXE6 B PJD001Z230 ...

Page 123: ... 120 Models FDUM112KXE6 140KXE6 B PJR002Z259 ...

Page 124: ... 121 h Duct connected Ultra thin Low static pressure type FDQS Models All models C PJC001Z200 ...

Page 125: ... 122 i Wall mounted type FDK Models FDK22KXE6 28KXE6 36KXE6 45KXE6 56KXE6 B PHA000Z983 ...

Page 126: ... 123 Models FDK71KXE6 B PHA000Z984 ...

Page 127: ... 124 j Ceiling suspended type FDE Models FDE36KXE6A 45KXE6A 56KXE6A B PFA003Z826 ...

Page 128: ... 125 Models FDE71KXE6A 112KXE6A 140KXE6A B PFA003Z827 ...

Page 129: ... 126 k Floor standing with casing type FDFL Models All models B PGD000Z053 ...

Page 130: ... 127 l Floor standing without casing type FDFU Models All models A PGD000Z058 ...

Page 131: ... 128 m Duct Connected Compact and Flexible type FDUH Models All models A PJC001Z255 ...

Page 138: ... 135 ...

Page 139: ... 136 ...

Page 143: ... 140 b ...

Page 144: ... 141 ...

Page 191: ... 188 5 4 Installation of outdoor unit ...

Page 193: ... 190 ...

Page 194: ... 191 ...

Page 195: ... 192 ...

Page 196: ... 193 ...

Page 197: ... 194 ...

Page 198: ... 195 ...

Page 199: ... 196 ...

Page 200: ... 197 ...

Page 201: ... 198 ...

Page 202: ... 199 ...

Page 203: ... 200 ...

Page 204: ... 201 ...

Page 205: ... 202 ...

Page 206: ... 203 ...

Page 207: ... 204 ...

Page 208: ... 205 ...

Page 210: ... 207 ...

Page 211: ... 208 ...

Page 212: ... 209 ...

Page 215: ... 212 2 model type DIS model type HEAD ...

Page 216: ... 213 2 2 ...

Page 217: ... 214 2 2 2 2 2 ...