Summary of Contents for FDE112KXE6A

Page 104: ... 102 ...

Page 111: ... 108 b Ceiling cassette 4 way Compact type FDTC Models All moddels B PJA003Z331 ...

Page 112: ... 109 c Ceiling cassette 2 way type FDTW Models FDTW28KXE6 45KXE6 56KXE6 B PJB001Z560 ...

Page 113: ... 110 Models FDTW71KXE6 90KXE6 B PJB001Z561 ...

Page 114: ... 111 Models FDTW112KXE6 140KXE6 B PJB001Z562 ...

Page 115: ... 112 d Ceiling cassette 1 way type FDTS Model FDTS45KXE6 A PJC001Z195 ...

Page 116: ... 113 Model FDTS71KXE6 A PJC001Z196 ...

Page 117: ... 114 e Ceiling cassette 1 way compact type FDTQ Models All models A PJC001Z190 ...

Page 118: ... 115 Models All models Duct panel A PJC001Z240 ...

Page 121: ... 118 Models FDU224KXE6 280KXE6 B PJD001Z230 ...

Page 123: ... 120 Models FDUM112KXE6 140KXE6 B PJR002Z259 ...

Page 124: ... 121 h Duct connected Ultra thin Low static pressure type FDQS Models All models C PJC001Z200 ...

Page 125: ... 122 i Wall mounted type FDK Models FDK22KXE6 28KXE6 36KXE6 45KXE6 56KXE6 B PHA000Z983 ...

Page 126: ... 123 Models FDK71KXE6 B PHA000Z984 ...

Page 127: ... 124 j Ceiling suspended type FDE Models FDE36KXE6A 45KXE6A 56KXE6A B PFA003Z826 ...

Page 128: ... 125 Models FDE71KXE6A 112KXE6A 140KXE6A B PFA003Z827 ...

Page 129: ... 126 k Floor standing with casing type FDFL Models All models B PGD000Z053 ...

Page 130: ... 127 l Floor standing without casing type FDFU Models All models A PGD000Z058 ...

Page 131: ... 128 m Duct Connected Compact and Flexible type FDUH Models All models A PJC001Z255 ...

Page 138: ... 135 ...

Page 139: ... 136 ...

Page 143: ... 140 b ...

Page 144: ... 141 ...

Page 191: ... 188 5 4 Installation of outdoor unit ...

Page 193: ... 190 ...

Page 194: ... 191 ...

Page 195: ... 192 ...

Page 196: ... 193 ...

Page 197: ... 194 ...

Page 198: ... 195 ...

Page 199: ... 196 ...

Page 200: ... 197 ...

Page 201: ... 198 ...

Page 202: ... 199 ...

Page 203: ... 200 ...

Page 204: ... 201 ...

Page 205: ... 202 ...

Page 206: ... 203 ...

Page 207: ... 204 ...

Page 208: ... 205 ...

Page 210: ... 207 ...

Page 211: ... 208 ...

Page 212: ... 209 ...

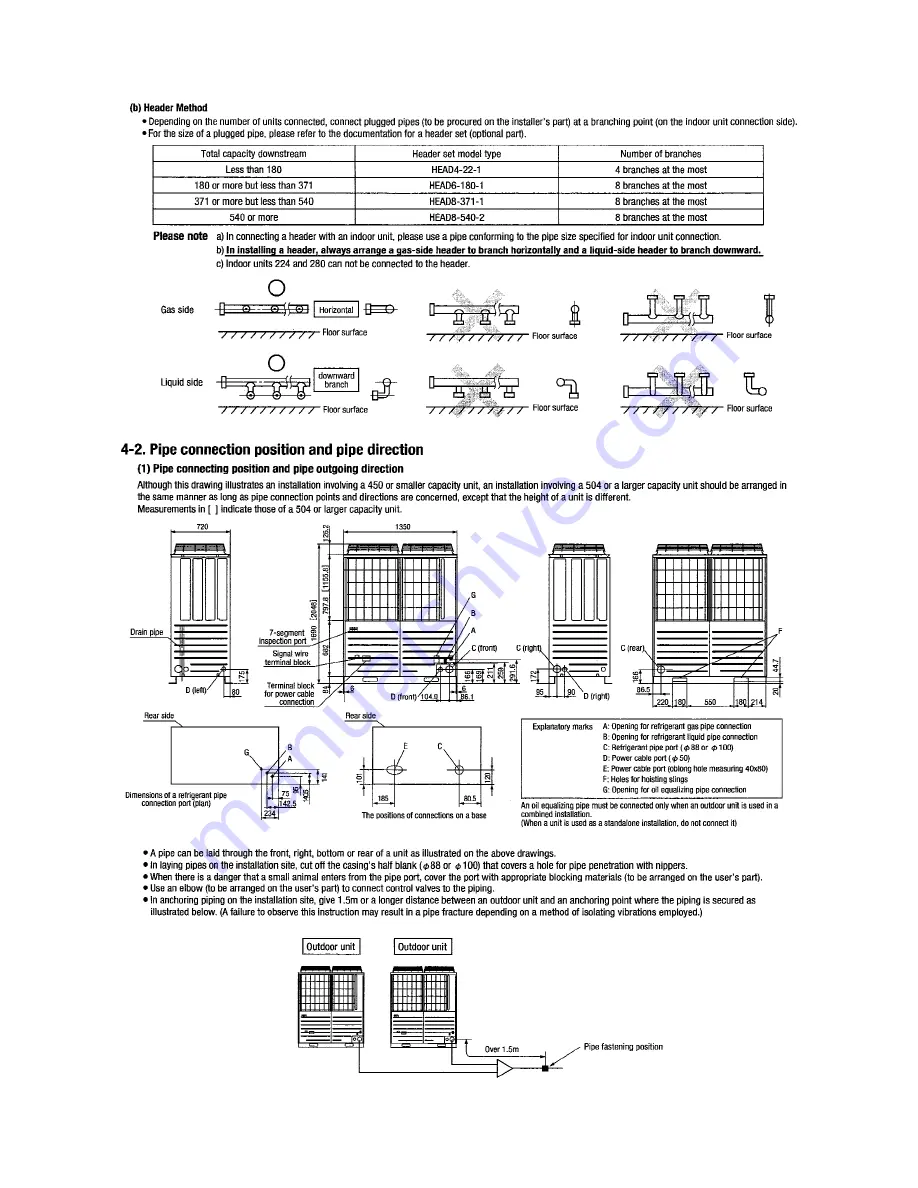

Page 215: ... 212 2 model type DIS model type HEAD ...

Page 216: ... 213 2 2 ...

Page 217: ... 214 2 2 2 2 2 ...