'18 • PAC-SM-297

-

35

-

■

Error log and reset

Error indicator

Memorized error log

Reset

Remote control display

• Higher priority error is memorized.

• Stop the unit by pressing the ON/OFF

switch of remote control.

• If the unit has recovered from anomaly, it

can be operated.

Red LED on indoor control PCB

• Not memorized.

Red LED on outdoor control PCB • Memorizes a mode of higher priority.

■

Resetting the error log

• Resetting the memorized error log in the remote control

Holding down “CHECK” button, press “TIMER” button to reset the error log memorized in the remote control.

• Resetting the memorized error log in the indoor unit

The remote control transmits error log erase command to the indoor unit when “VENTI” button is pressed

while holding down “CHECK” button.

Receiving the command, the indoor unit erase the log and answer the status of no error.

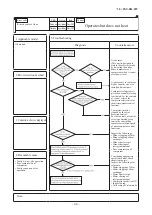

(2) Troubleshooting procedure

When any trouble has occurred, inspect as follows. Details of respective inspection method will be described on later pages.

Trouble

Confirmation

of power

source

(Indoor/

outdoor unit)

Confirmation of

remote control and

LEDs on the PCB

of indoor unit and

outdoor unit (Indoor/

outdoor unit, remote

control)

Check of the anomalous

operation data on the

remote control

Inspection

of the unit/

control

Replacement/

repair of

faulty part,

test run,

adjustment

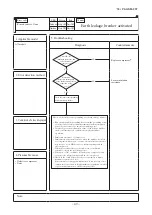

(3) Troubleshooting at the indoor unit

(a) FDTC, FDE, FDUM series

With the troubleshooting, find out any defective part by checking the voltage (AC, DC), resistance, etc. at respective

connectors at around the indoor PCB, according to the inspection display or operation status of unit (the compressor

does not run, fan does not run, the 4-way valve does not switch, etc.), and replace or repair in the unit of following part.

(i) Replacement part related to indoor PCB’s

Control PCB, power source PCB, temperature sensor (return air, indoor heat exchanger), remote control switch,

limit switch, transformer and fuse

Note (1) With regard to parts of high voltage circuits and refrigeration cycle, judge it according to ordinary inspection methods.

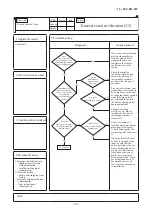

(ii) Instruction of how to replace indoor control PCB

ە

Read the "SAFETY PRECAUTIONS" carefully first of all and then strictly follow it during the replacement in order to protect yourself.

ە

The precautionary items mentioned below are distinguished into two levels, WARNING and CAUTION.

Both mentions the important items to protect your health and safety so strictly follow them by any means.

WARNING

Wrong installation would cause serious consequences such as injuries or death.

CAUTION

Wrong installation might cause serious consequences depending on circumstances.

ە

After completing the replacement, do commissioning to confirm there are no anomaly.

ە

Replacement should be performed by the specialist.

If you replace the PCB by yourself, it may lead to serious trouble such as electric shock or fire.

ە

Replace the PCB correctly according to these instructions.

Improper replacement may cause electric shock or fire.

ە

Shut off the power before electrical wiring work.

Replacement during the applying the current would cause the electric shock, unit failure or improper running.

It would cause the damage of connected equipment such as fan motor,etc.

ە

Fasten the wiring to the terminal securely, and hold the cable securely so as not to apply unexpected stress on the terminal.

Loose connections or hold could result in abnormal heat generation or fire.

ە

Check the connection of wiring to PCB correctly before turning on the power, after replacement.

Defectiveness of replacement may cause electric shock or fire.

ە

In connecting connector onto the PCB, connect not to deform the PCB. It may cause breakage or malfunction.

ە

Insert connecter securely, and hook stopper. It may cause fire or improper running.

ە

Bundle the cables together so as not to be pinched or be tensioned. It may cause malfunction or electric shock for disconnection or deformation.

ࠉࠉࠉࠉࠉࠉࠉࠉࠉ

CAUTION

SAFETY PRECAUTIONS

ࠉࠉࠉࠉࠉࠉࠉࠉࠉࠉ

WARNING

Summary of Contents for FDE40ZSXVH

Page 46: ... 18 PAC SM 297 45 ...