-

3

-

'10 • PAC-SM-137

A

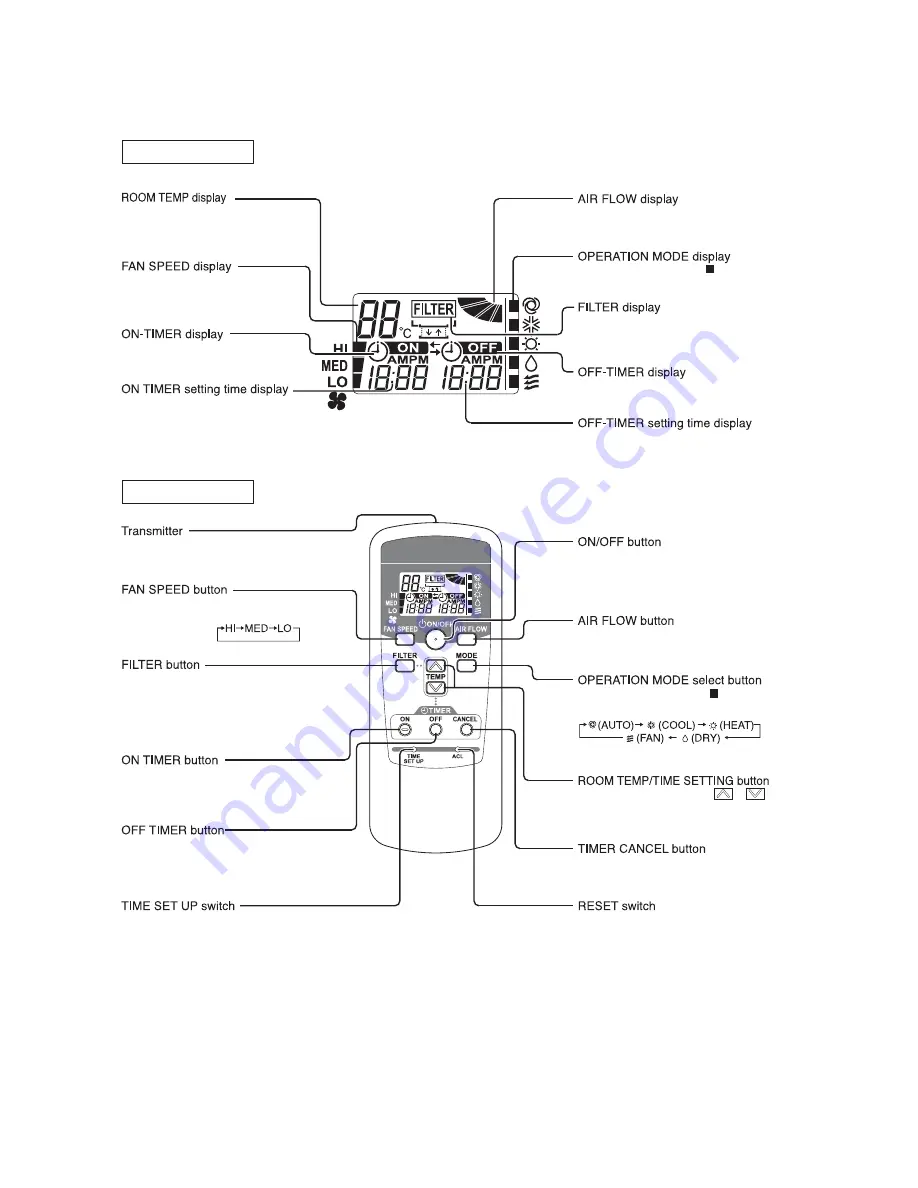

(2) Wireless remote controller

FDEN series only

* All displays are described in the liquid crystal display for explanation

Indication section

Operation section

Indicates set temperature.

Indicates the status of swing louver.

Indicates selected operation with .

Indicates for two seconds when FILTER

button is pressed.

Indicates when OFF-TIMER is set.

Indicates OFF-TIMER setting time. Indicates the

current time when the OFF-TIMER is not set.

When this is pressed once, the unit starts to

operate and when this is pressed once again,

it stops operating.

Used to swing the louver.

Every time this button is pressed, displays switch

as below.

Sets room temperature by pressing or button.

Sets time when setting the time.

Used to cancel the TIMER SETTINGS.

Used to reset the microcomputer.

Indicates the selected airflow volume

Indicates when ON-TIMER is set.

Indicates the ON-TIMER setting time.

Nothing displayed when ON-TIMER is

not set.

Sends signal to the air conditioner.

Every time this button is pressed, the mode is

switched as below.

Used to reset (turn off) the filter sign.

Press the button only after completing

the filter cleaning.

Sets ON TIMER operation.

Sets OFF TIMER operation.

Sets current time.

Summary of Contents for FDEN125VNXVD

Page 101: ... 101 10 PAC SM 137A ...

Page 106: ... 106 10 PAC SM 137A 2 Models FDC100 140VNX 100 140VSX ...

Page 107: ... 107 10 PAC SM 137A ...

Page 108: ... 108 10 PAC SM 137A ...

Page 109: ... 109 10 PAC SM 137A ...

Page 110: ... 110 10 PAC SM 137A ...

Page 111: ... 111 10 PAC SM 137A ...

Page 112: ... 112 10 PAC SM 137A ...

Page 113: ... 113 10 PAC SM 137A ...

Page 114: ... 114 10 PAC SM 137A 5 4 Electric wiring work installation ...

Page 115: ... 115 10 PAC SM 137A ...

Page 116: ... 116 10 PAC SM 137A ...

Page 117: ... 118 10 PAC SM 137A ...

Page 118: ... 118 10 PAC SM 137A ...