-

89

-

(iii) Open-phase protection (FDCA 301~601 3-phase models only), Abnormal compressor winding

temperature

1) When the detected current on the secondary side of the 52C is 1.5 ~ 2 A or lower continuously for 4 seconds while the

compressor is ON, it is judged that there is an open-phase problem and the compressor is stopped. After a 3-minute

delay, the compressor is restarted, but if the problem occurs a second time within 60 minutes of the first detection, an

abnormal stop (E34) is performed.

2) When the temperature of the compressor windings is abnormal, and internal thermostat built into the compressor

operates. This is judged as an open-phase problem and results in an abnormal stop (E32). In single phase machines,

this is sensed by CT1.

Note (1) If the internal thermostat operates, it takes a long time to recover. Please do not mistake this as a defect in the compressor.

(iv) Discharge pipe temperature control

If the discharge pipe temperature (sensed by Tho-D) exceeds the set value, the compressor speed (in the 151~251

models) or the expansion valve opening angle (in the 301~601 models) is controlled to prevent the discharge pipe

temperature from rising. If it continues to rise anyway, the compressor is stopped.

2) Defrosting start temperature change procedure

Turn SW5-1 on the outdoor unit PCB ON.

a) A cumulative total of 30 minutes of compressor operating time has passed since defrosting ended.

b) When the temperature at the outdoor heat exchanger thermistor (Tho-R) and the temperature at the outdoor air

temperature thermistor (Tho-A) is below the defrost operation start temperature continuously for 30 seconds.

c) Other than items a) and b), the same as standard conditions.

3) Defrosting end conditions

If any of the following conditions is satisfied, the defrosting end operation starts.

a) If 10 minutes

(1)

have passed since defrosting started.

b) If the temperature at the outdoor heat exchanger thermistor (Tho-R) is 12ºC or higher (in the case of models 151~251),

or 14ºC or higher (in the case of models 301~601) continuously for 2 seconds.

Notes (1) This setting can be changed to 12 minutes by turning SW5-1 on the outdoor unit PCB ON.

Notes

(2) When SW-1 on the outdoor unit’s control board is ON, or when JA4 is open (in the case of the 151~251 models) or jumper wire J6 (when

SW-6 is ON) (in the case of the 301 ~ 601 models) is open, raise the defrosting end temperature and carry out forced defrosting.

(g) Compressor protection control

(i)

Compressor overcurrent protection

1) 7 If a value at or higher than the set value is detected continuously for approximately 0.5 second in the L1 and L2

phases (1 phase model: L phase) on the secondary side of the 52C (sensed by the current sensor (CT)), the compres-

sor stops. After a 3-minute delay, the compressor restarts if the detected current is 1.5 ~ 2 A or lower, but if this

condition is repeated 5 times within 60 minutes of the first detection, the unit is subjected to an abnormal stop

(E33).

2) After the compressor stops the first time, if 60 seconds pass with the detected current not dropping to 1.5~2 A or

lower for 60 minutes, An abnormal stop is performed after the first time.

(ii)

Reverse phase protection (FDCA 301~601 3-phase models only)

The phase sequence in the 52C secondary side is detected, and in cases other than those shown below, reverse phase is

judged and the unit is subjected to an abnormal stop (E32).

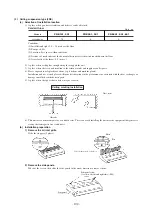

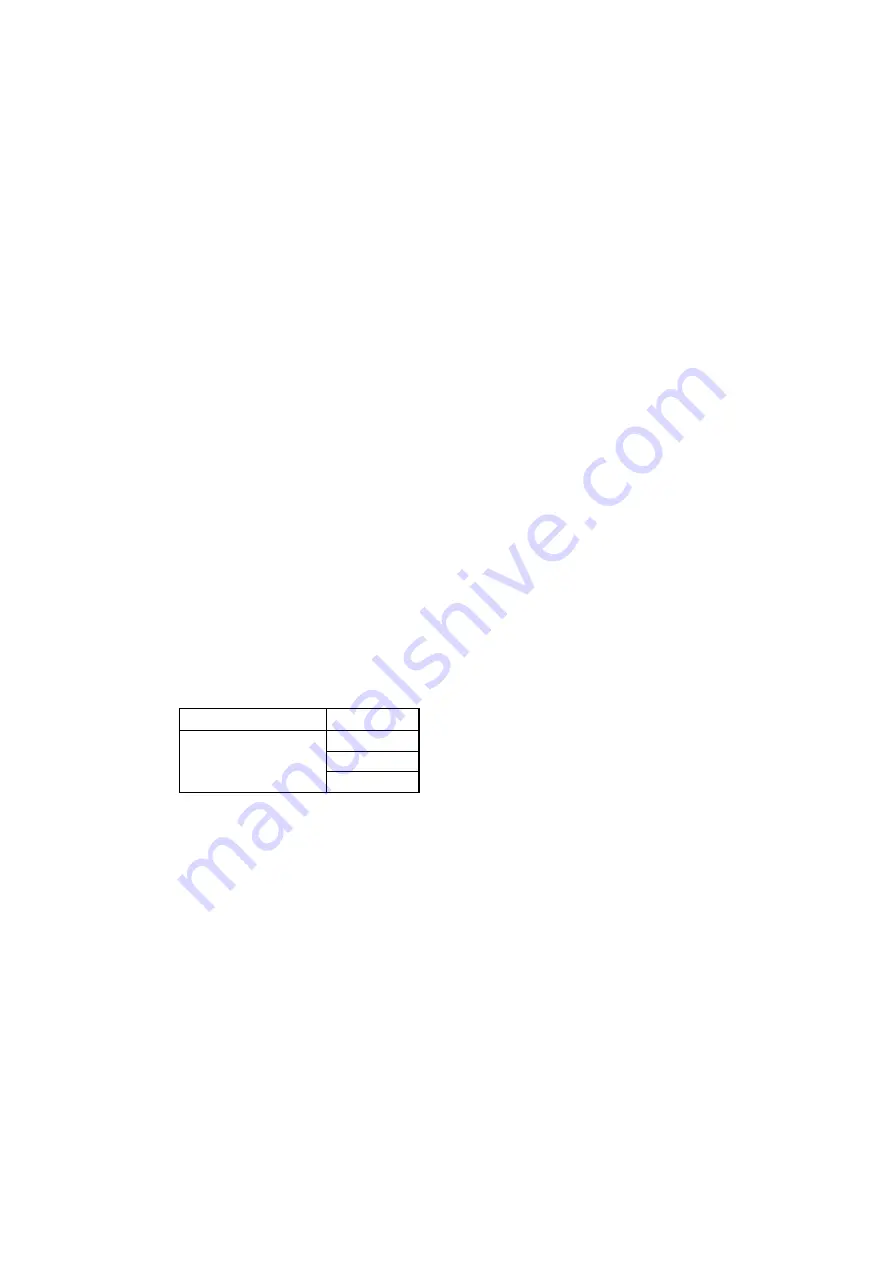

Terminal block display

Wire connections

L1 · L2 · L3 · N

L1 · L2 · L3 · N

L3 · L1 · L2 · N

L2 · L3 · L1 · N