–

–

'17 • KX-T-259

⑨

Check list after installation

Check the following items after all installation work completed.

Check if;

The indoor and outdoor units are fixed securely?

Inspection for leakage is done?

Insulation work is properly done?

Water is drained properly?

Power source voltage is same as mentioned in the model name plate ?

There is mis-wiring or mis-connection of piping?

Earth wiring is connected properly?

Cable size comply with specified size?

Any obstacle blocks air flow on air inlet and outlet?

Check

Expected trouble

Falling, vibration, noise

Insufficient capacity

Water leakage

Water leakage

PCB burnt out, not working at all

PCB burnt out, not working at all

Electric shock

PCB burnt out, not working at all

Insufficient capacity

④

Installation of indoor unit (continued)

⑧

Wiring-out position and wiring connection (continued)

⑥

Refrigerant pipe

⑦

Drain pipe (continued)

Be sure to use new pipes for the refrigerant pipes. Use the flare nut attached to the product or

a nut compatible with JIS B 8607, Class 2.

Regarding whether existing pipes can be reused or not, and the washing method, refer to the instruction manual of the

outdoor unit, catalogue or technical data.

1) In case of reuse: Do not use old flare nut, but use the one attached to the unit or compatible with JIS B 8607, Class 2.

2) In case of reuse: Flare the end of pipe replaced partially for R410A.

Use phosphorus deoxidized copper alloy seamless pipe (C1220T specified in JIS H3300) for refrigeration pipe installation.

In addition, make sure there is no damage both inside and outside of the pipe, and no harmful

substances such as sulfur, oxide, dust or a contaminant stuck on the pipes.

Do not use any refrigerant other than R410A.

Using other refrigerant except R410A (R22 etc.) may degrade inside refrigeration oil. And air getting into

refrigeration circuit may cause over-pressure and resultant it may result in bursting, etc.

Store the copper pipes indoors and seal the both end of them until they are brazed in order to avoid any dust, dirt or

water getting into pipe. Otherwise it will cause degradation of refrigeration oil and compressor breakdown, etc.

Use special tools for R410A refrigerant.

Address setting

Remove the front panel of indoor unit and the control cover, it is possible to change address setting.

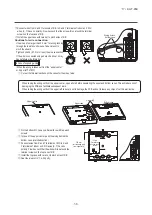

1. Remove the front panel

①

Remove the air inlet panel.

②

Remove the 2 screws in the cap of bottom panel. (Type 15 - 56 only)

③

Remove the 2 hooks of left and right side and then bottom panel can be removed. (Type 15

- 56 only)

④

Remove the screws (Type 15 - 56: 2 screws, Type 71, 90: 5 3 screws (in the cap))

⑤

Remove the upper latches and then front panel can be removed. (Type 15 - 56: 4 latches,

Type 71, 90: 5 latches)

2. Install the front panel

①

Cover the unit with the front panel and fix upper latches (Type 15 - 56: 4 latches, Type 71,

90: 5 latches)

②

Fix the front panel with the screws (Type 15 - 56: 2 screws, Type 71, 90: 5 3 screws

(in the cap))

③

Install the 2 hooks of left and right side and then bottom panel can be installed. (Type 15 - 56

only)

④

Fix the bottom panel with 2 screws in the cap. (Type 15 - 56 only)

⑤

Install the air inlet panel.

Caution

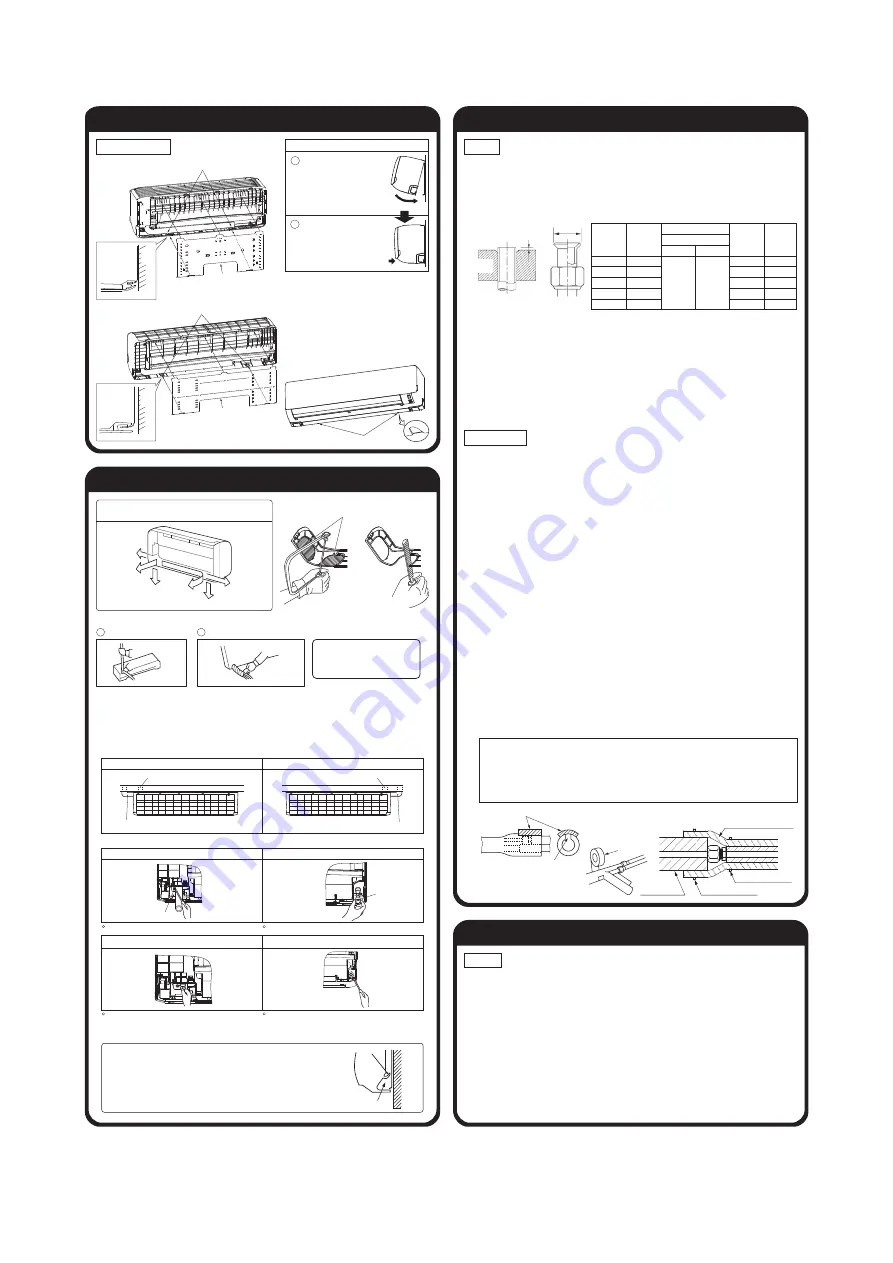

D

Protruding

dimension

Flare die

d

mm

6.35

9.52

12.7

15.88

19.05

For R410A Conventional tool

Pipe dia.

Min. pipe

wall thickness

Protruding dimension for flare, mm

Rigid (Clutch type)

Flare O.D.

Flare nut

tightening torque

0

-

0.5

0.7

-

1.3

D

mm

8.9

-

9.1

12.8

-

13.2

16.2

-

16.6

19.3

-

19.7

23.6

-

24.0

N·m

14

-

18

34

-

42

49

-

61

68

-

82

100

-

120

mm

0.8

0.8

0.8

1

1.2

1. Remove the flare nut and blind flanges on the pipe of the indoor unit.

※

Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving torque to the

nut with another spanner in order to avoid unexpected stress to the copper pipe, and then remove them.

(Gas may come out at this time, but it is not abnormal.)

Pay attention whether the flare nut pops out. (as the indoor unit is sometimes pressured.)

2. Make a flare on liquid pipe and gas pipe, and connect the refrigeration pipes on the indoor unit.

※

Bend radius of pipe must be 4D or larger. Once a pipe is bent, do not readjust the bending.

Do not twist a pipe or collapse to 2/3D or smaller.

※

Do a flare connection as follows:

Make sure to loosen the flare nut with holding the nut on pipe side with a spanner and giving

torque to the nut with another spanner in order to avoid unexpected stress to the copper pipe,

and then remove them.

When fastening the flare nut, align the refrigeration pipe with the center of flare nut, screw

the nut for 3-4 times by hand and then tighten it by spanner with the specified torque

mentioned in the table above. Make sure to hold the pipe on the indoor unit securely by a

spanner when tightening the nut in order to avoid unexpected stress on the copper pipe.

3. Cover the indoor unit’s flare-connected joints, after they are checked for a gas leak, with an

indoor unit heat insulating material and then wrap them with a tape with an attached insula-

tion pad placed over the heat insulating material’s slit area.

Make sure to insulate both gas pipes and liquid pipes completely.

※

Incomplete insulation may cause dew condensation or water dropping.

Use heat-resistant (120 °C or more) insulations on the gas side pipes.

In case of using at high humidity condition, reinforce insulation of refrigerant pipes.

Surface of insulation may cause dew condition or water dropping, if insulations are not

reinfoced.

4. Refrigerant is charged in the outdoor unit.

As for the additional refrigerant charge for the indoor unit and piping, refer to the installation

manual attached to the outdoor unit.

Work procedure

Refrigerating machine oil should not be applied to the threads of union or external surface of flare. It

is because, even if the same tightening torque is applied, the oil is likely to decrease the slide friction

force on the threads and increase, in turn, the axial component force so that it could crack the flare

by the stress corrosion.

Refrigerating machine oil may be applied to the internal surface of flare only.

Caution:

Arrange the drain hose in a downward angle

Avoid the following drain piping.

When the extended drain hose is present inside the room, always use a shield pipe (prepare

on site) and ensure it is thermally insulated

Shield pipe

Drain hose

Extended drain hose

When it is exposed indoor.

3 Pour water to the drain pan located under the heat exchanger, and ensure that water is discharged

the outdoor.

(For removal of the front panel, refer to

⑧

Wiring-out position and wiring connection

in this manual.

1. A general-purpose hard PVC pipe VP16 can be connected to the drain hose tip as a part of

drain piping.

2. Drain piping must be given a descending grade so that drain water may flow smoothly and it

must not have any trap or bump within the system.

(The pipe can be routed through the left, right, rear or bottom of the unit)

Hard PVC pipes (VP16) laid indoors must be kept warm.

⑦

Drain pipe

Caution

Install the drain pipe according to the installation manual in order to drain properly.

Imperfection in draining may cause flood indoors and wetting the household goods,etc.

Do not put the drain pipe directly into the ditch where toxic gas such as sulfur, the other harmful and

inflammable gas is generated. Toxic gas would flow into the room and it would cause serious

damage to user’s health and safety (some poisoning or deficiency of oxygen). In addition, it may

cause corrosion of heat exchanger and bad smell.

Connect the pipe securely to avoid water leakage from the joint.

Insulate the pipe properly to avoid condensation drop.

Check if the water can flow out properly from both the drain outlet on the indoor unit and the end

of the drain pipe after installation.

Make sure to make descending slope of greater than 1/100 and do not make up-down bend and/or trap in

the midway. In addition, do not put air vent on the drain pipe. Check if water is drained out properly from

the pipe during commissioning. Also, keep sufficient space for inspection and maintenance.

Fixing of indoor unit

Shaping of pipes and drain hoses

<In case of piping in the right rear direction>

Shaping of pipes

Tape wrapping

Pipe

Drain hose

Make sure that wires are connected

securely onto the terminal block,

before you wrap them with a tape

after shaping the pipe.

Installation

board

Indoor unit base latch

Wall

Installation board

Indoor unit

Latch (2 locations)

Installation board

Installation

board

Indoor unit base latch

Wall

Indoor unit

Latch (2 locations)

Type 71, 90

Type 15~56

t)PXUPSFNPWFUIFJOEPPSVOJUGSPN

the

installation board

①

Push up at the marked portion of the indoor unit

base lower latch, and slightly pull it toward you.

(both right and left hand sides) (The indoor unit

base lower latch can be removed from the

installation board)

②

Push up the indoor unit upward so that it can be

removed from installation board.

Latch

2

1

Gently push the lower part to

secure the unit.

Pass the pipe through the hole

in the wall, and hook the upper

part of the indoor unit to the

installation board.

Cut out the panel smoothly along the

line in case of side or bottom piping.

Piping is possible in the rear, left, left rear, left downward,

right or downward direction.

Right

Right rear

Right

downward

Left

rear

Left downward

Left

Tape only the portion that goes through the wall.

Always tape the wiring with the piping.

The connecting wires must be wrapped together with the pipe.

Hold the bottom of the

piping and fix direction

before stretching it and

shaping it.

Piping in the left direction

Piping in the right rear direction

Piping in the left rear direction

Piping in the right direction

[Top view]

t.BUUFSTPGTQFDJBMOPUJDFXIFOQJQJOHGSPNMFGUPSDFOUSBMSFBSPG

the unit.

Left-hand-side piping

Right-hand-side piping

[Drain hose changing procedures]

1. Remove the drain hose

2. Remove the drain cap.

Remove it with hand or pliers.

Remove the screw and drain hose, making it rotate.

3. Insert the drain cap.

4. Connect the drain hose.

Insert the drain cap which was removed at procedure “2”

securely using a hexagonal wrench etc.

Note: Be careful that If it is not inserted securely, water

leakage may occur.

Insert the drain hose securely, making rotate. And install the

screw.

Note: Be careful that If it is not inserted securely, water

leakage may occur.

screw

cap

Band (Prepare on site)

Band (Prepare on site)

Insulation

(Prepare on site)

Pipe cover (Prepare on site)

<The case of using reinforced insulation at the outside of unit>

Vinyl tape

Use an attached insulation pad for heat insulation.

Position it so that the slit area faces upward.

Higher than specified

Wavy

The drain hose

tip is in water.

The gap to the ground is

5 cm or less.

The drain hose

tip is in the gutter.

Odor from

the gutter

Electrical installation work must be performed according to the installation manual by an

electrical installation service provider qualified by a power provider of the country, and be

executed according to the technical standards and other regulations applicable to electrical

installation in the country.

Be sure to use an exclusive circuit.

Use specified cord, fasten the wiring to the terminal securely, and hold the cord securely in

order not to apply unexpected stress on the terminal.

Do not put both power source line and signal line on the same route. It may cause miscom-

munication and malfunction.

Be sure to do D type earth work.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

For the details of electrical wiring work, see attached instruction manual for electrical wiring

work.

⑧

Wiring-out position and wiring connection

Signal side

terminal block

Power source side

terminal block

Earth

Band

Band

Superlink line

Remote control line

Power source line

In case of band is over length,

cut off the band.

①

Pull the air inlet panel at both ends of lower part and release latches, then pull up the panel until

you feel resistance. (The panel stops at approx 60 - 70° open position.)

②

Remove the screw and the lid.

③

Connect wiring securely to the terminal block.

④

Fix wiring the clamp securely, in order not to transmit unexpected stress on the terminal.

⑤

Fix the lid and the screw.

⑥

Close the air inlet panel.

(Note)

Connect wiring to the terminal block, check number on label of the terminal block.

Wall

Gutter

Pipe accommodating section

Since this air-conditioner has been designed to collect dew drops on the rear

surface to the drain pan, do not attach the power cable above the gutter.

Installation Steps

Signal side

terminal block

Power source side

terminal block

Earth

Band

Band

Superlink line

Remote control line

Power source line

PHA012D401

Type 15-56

Type 15-56

Type 71, 90

Type 15-56

Type 71, 90

Type 71, 90

Air inlet panel

Front panel

Front panel

Air inlet panel

Screw

Screw (in the cap)

Latch

Screw

Screw

Control cover

Control cover

Address switch

Bottom panel

Screw (in the cap)

Screw

Latch

Address switch

Lid

Type 15-56

Type 71, 90

Lid

⑤