–

58

–

'17 • KX-T-259

-

125

-

'16 • PAC-T-251

(c) Operation check mode

There is no communication with the outdoor unit but it allows performing operation in respective modes by operating the

remote control.

(d) Drain pump test run mode

As the drain pump test run is established, the drain pump only operates and during the operation protective functions by

the microcomputer of indoor unit become ineffective.

(14) Cooling, dehumidifying frost protection

(a) To prevent frosting during cooling mode or dehumidifying mode operation, the of compressor speed is reduced if

the indoor heat exchanger temperature (detected with Thi-R) drops to 1.0 °C or lower at 4 minutes after the start of

compressor operation. If the indoor unit heat exchanger temperature is 1.0 °C or lower after 1 minutes, the compressor

speed is reduced further. If it becomes 2.5 °C or higher, the control terminates. When the indoor heat exchanger

temperature has become as show below after reducing the compressor speed, it is switched to the fan operation. For the

selection of indoor fan speed, refer to item 2).

10

1.0

Indoor heat exchanger temperature (°C)

Fan operation

Cooling operation

(b) Selection of indoor fan speed

If it enters the frost prevention control during cooling operation (excluding dehumidifying), the indoor fan speed is

switched.

(i) When the indoor return air detection temperature (detected with Thi-A) is 23°C or higher and the indoor heat

exchanger temperature (detected with Thi-R) detects the compressor frequency drop start temperature A°C+1°C, of

indoor fan speed is increased by 20min

-1

.

(ii) If the phenomenon of (i) above is detected again after the acceleration of indoor fan, indoor fan speed is increased

further by 20min

-1

.

Note (1) Indoor fan speed can be increased by up to 2 taps.

• Compressor frequency drop start temperature

Symbol

Item

A

Temperature - Low (Factory default)

1.0

Temperature - High

2.5

Note (1) Frost prevention temperature setting can be selected with the indoor unit function setting of the wired remote control.

(15) Heating overload protection

(a) If the indoor heat exchanger temperature (detected with Thi-R) at 63°C or higher is detected for 2 seconds continuously,

the compressor stops. When the compressor is restarted after a 3-minute delay, if a temperature at 63°C or higher is

detected for 2 seconds continuously within 60 minutes after initial detection and if this is detected 5 times consecutively,

the compressor stops with the anomalous stop (E8). Anomalous stop occurs also when the indoor heat exchanger

temperature at 63°C or higher is detected for 6 minutes continuously.

56

63

Indoor heat exchanger temperature (°C)

Compressor ON

Compressor OFF

(b) Indoor fan speed selection

If, after second detection of heating overload protection up to fourth, the indoor fan is set at Me and Lo taps when the

compressor is turned ON, the indoor fan speed is increased by 1 tap.

(13) Anomalous fan motor

(a)

After starting the fan motor, if the fan motor speed is 200min

-1

or less is detected for 30 seconds continuously and 4 times

within 60 minutes, then fan motor stops with the anomalous stop (E16).

(b) If the fan motor fails to reach at -50

min

-1

less than the required speed, it stops with the anomalous stop (E20).

(11) Operation check mode

(a) If the power is turned on by the dip switch (SW7-1) on the indoor PCB when electric power source is supplied, it enters the

mode of operation check. It is ineffective (prohibited) to change the switch after turning power on.

(b) When the communication with the remote control has been established within 60 seconds after turning power on by the

dip switch (SW7-1) ON, it enters the operation check mode.

(c) Operation check mode

There is no communication with the outdoor unit but it allows performing operation in respective modes by operating the

remote control.

(12) Cooling, dehumidifying frost protection

(a) To prevent frosting during cooling mode or dehumidifying mode operation, the of thermostat-OFF if the indoor heat

exchanger temperature (detected with ThI-R) drops to 1.0 °C or lower at 4 minutes after the thermostat-ON. If the indoor

unit heat exchanger temperature is 1.0 °C or lower after 5 minutes, the indoor unit is controlled thermostat-OFF. If it

becomes 10°C or higher, the control terminates. When the indoor heat exchanger temperature has become as show, the

indoor unit send outdoor unit the “Anti-frost” signal.

10

A

Indoor heat exchanger temperature (°C)

Thermostat-OFF

5 minutes

Thermostat-ON capable

SRC40~60

FDC100~140

Model

Symbol

A

4

4

1

1

1.0

1.0

2.5

2.5

B

C

D

• Frost prevention temperature setting can be selected with the

indoor unit function setting of the wired remote control.

Symbol

Item

A

Temperature - Low (Factory default)

1.0

Temperature - High

2.5

-

126

-

'16 • PAC-T-251

(14) Plural unit control – Control of 16 units group by one remote control

(a

) Function

One remote control can control a group of multiple number of unit (Max. 16 indoor units). “Operation mode” which is

set by the remote control can operate or stop all units in the group one after another in the order of unit. No.

(1)

. Thermostat

and protective function of each unit function independently.

Note (1) Unit No. is set by SW1, SW2 and SW5-2 on the indoor control PCB. Unit No. setting by SW2 is necessary for the indoor unit only. In cases of the twin, triple and

double twin specification, it is necessary set for the master and the slave units. This can be selected by SW5. (All are set for the master unit at the

shipping from factory.)

(2) Unit No. may be set at random unless duplicated, it should be better to set orderly like 0, 1, 2…, F to avoid mistake.

(b) Display to the remote control

(i) Central or each remote control basis, heating preparation: the smallest unit No. among the operating units in the

remote mode (or the center mode unless the remote mode is available) is displayed.

(ii) Inspection display, filter sign: Any of unit that starts initially is displayed.

(c) Confirmation of connected units

(i) In case of RC-EX3 remote control

If you touch the buttons in the order of “Menu”

→

“Service setting”

→

“Service & Maintenance”

→

“IU address”

on the TOP screen of remote control, the indoor units which are connected are displayed.

(ii) In case of RC-E5 remote control

Pressing “AIR CON No.” button on the remote control displays the indoor unit address. If “

▲

” “

▼

” button is

pressed at the next, it is displayed orderly starting from the unit of smallest No.

(d) In case of anomaly

If any anomaly occurs on a unit in a group (a protective function operates), that unit stops with the anomalous stop but

any other normal units continue to run as they are.

(e)

Signal wiring procedure

Signal wiring between indoor and outdoor units should be made on each unit same as the normal wiring. For the group

control, connect the remote control wiring to each indoor unit via terminal block for the remote control.

Connect the remote control wiring separately from the power source cable or wires of other electric devices (AC220V or

higher).

(18) High ceiling control

When sufficient air flow rate cannot be obtained from the indoor unit which is installed at a room with high ceiling, the air flow

rate can be increased by changing the fan tap. To change the fan tap, use the indoor unit function “FAN SPEED SET” on the

wired remote control.

-

-

-

-

-

-

-

STANDARD

HIGH SPEED1

[Setting 1]

[Setting 2]

HIGH SPEED2

FAN SPEED SET

Hi - ULo

Hi - Lo

Hi - Me

Hi - Me - ULo

Hi - Me - Lo

PHi2 - Hi - Me - ULo

PHi1 - Hi

PHi1 - Me

PHi1 - Hi - Me

PHi2 - PHi1 - Hi - Me

PHi2 - Hi - Me - Lo

Indoor unit airflow setting

Fan tap

Hi - Me

Notes (1) Factory default is STANDARD.

(2) At the hot-start and heating thermostat OFF, or other, the indoor fan is operated at the low speed tap of each setting.

(3) This function is not able to be set with wireless remote controls or simple remote control (RCH-E3)

(4) Values in [ ] are for the RC - EX3 models.

SW2: For setting of 0 – 9, A – F

SW5: For setting of master and slave units

(See table shown at right.)

Remote control

Indoor unit

Outdoor unit

Signal wiring

between outdoor unit

and indoor units

(Master unit)

(Slave unit a)

(Slave unit b)

Remote control wiring

R

0

1

2

3

F

4

4

4

(Slave unit c)

4

Refrigerant piping

Master unit

OFF

OFF

OFF

ON

SW5-1

SW5-2

ON

OFF

ON

ON

Slave unit a

Slave unit b

Slave unit c

Switch

Unit

SW5 setting

P2.indb 126

2/20/2017 1:08:37 PM

C

M

Y

CM

MY

CY

CMY

K

P58-1.pdf 2017/03/21 12:38:12

-

125

-

'16 • PAC-T-251

(c) Operation check mode

There is no communication with the outdoor unit but it allows performing operation in respective modes by operating the

remote control.

(d) Drain pump test run mode

As the drain pump test run is established, the drain pump only operates and during the operation protective functions by

the microcomputer of indoor unit become ineffective.

(14) Cooling, dehumidifying frost protection

(a) To prevent frosting during cooling mode or dehumidifying mode operation, the of compressor speed is reduced if the

indoor heat exchanger temperature (detected with Thi-R) drops to A °C or lower at 4 minutes after the start of compressor

operation. If the indoor unit heat exchanger temperature is A °C or lower after 1 minutes, the compressor speed is reduced

further. If it becomes B °C or higher, the control terminates. When the indoor heat exchanger temperature has become

as shown below after reducing the compressor speed, it is switched to the fan operation. For the selection of indoor fan

speed, refer to item (b).

When the indoor return air detected relative humidity (detected with HS) is lower than 50%, the temperature A and B is

changed as shown in the table.

10

A

Indoor heat exchanger temperature (°C)

Fan operation

Cooling operation

(b) Selection of indoor fan speed

If it enters the frost prevention control during cooling operation (excluding dehumidifying), the indoor fan speed is

switched.

(i) When the indoor return air detection temperature (detected with Thi-A) is 23°C or higher and the indoor heat

exchanger temperature (detected with Thi-R) detects the compressor frequency drop start temperature A°C+1°C, of

indoor fan speed is increased by 20min

-1

.

(ii) If the phenomenon of (i) above is detected again after the acceleration of indoor fan, indoor fan speed is increased

further by 20min

-1

.

Note (1) Indoor fan speed can be increased by up to 2 taps.

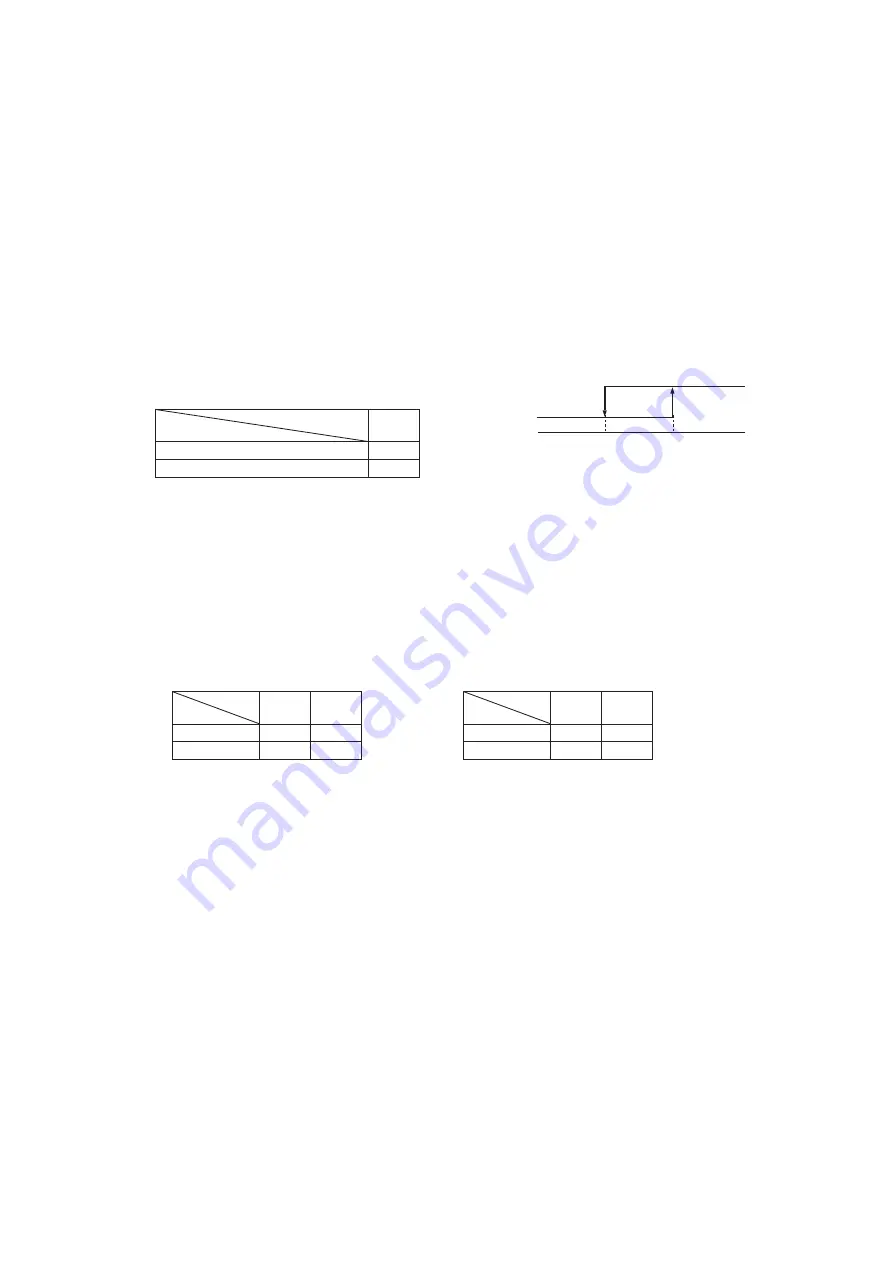

• Compressor frequency drop start temperature

Hs

>

50%

Hs

≦

50%

Item

Symbol

Low

High

Item

Symbol

Low

High

A

1.0

2.5

A

-0.5

1.0

B

2.5

4.0

B

1.0

2.5

Note (1) Frost prevention temperature setting can be selected with the indoor unit function setting of the wired remote control.

(15) Heating overload protection

(a) If the indoor heat exchanger temperature (detected with Thi-R) at 63°C or higher is detected for 2 seconds continuously,

the compressor stops. When the compressor is restarted after a 3-minute delay, if a temperature at 63°C or higher is

detected for 2 seconds continuously within 60 minutes after initial detection and if this is detected 5 times consecutively,

the compressor stops with the anomalous stop (E8). Anomalous stop occurs also when the indoor heat exchanger

temperature at 63°C or higher is detected for 6 minutes continuously.

56

63

Indoor heat exchanger temperature (°C)

Compressor ON

Compressor OFF

(b) Indoor fan speed selection

If, after second detection of heating overload protection up to fourth, the indoor fan is set at Me and Lo taps when the

compressor is turned ON, the indoor fan speed is increased by 1 tap.

(16) Anomalous fan motor

(a)

After starting the fan motor, if the fan motor speed is 200min

-1

or less is detected for 30 seconds continuously and 4 times

within 60 minutes, then fan motor stops with the anomalous stop (E16).

(b) If the fan motor fails to reach at -50

min

-1

less than the required speed, it stops with the anomalous stop (E20).

P2.indb 125

2/20/2017 1:08:37 PM

-

126

-

'16 • PAC-T-251

(14) Plural unit control – Control of 16 units group by one remote control

(a

) Function

One remote control can control a group of multiple number of unit (Max. 16 indoor units). “Operation mode” which is

set by the remote control can operate or stop all units in the group one after another in the order of unit. No.

(1)

. Thermostat

and protective function of each unit function independently.

Note (1) Unit No. is set by SW1, SW2 and SW5-2 on the indoor control PCB. Unit No. setting by SW2 is necessary for the indoor unit only. In cases of the twin, triple and

double twin specification, it is necessary set for the master and the slave units. This can be selected by SW5. (All are set for the master unit at the

shipping from factory.)

(2) Unit No. may be set at random unless duplicated, it should be better to set orderly like 0, 1, 2…, F to avoid mistake.

(b) Display to the remote control

(i) Central or each remote control basis, heating preparation: the smallest unit No. among the operating units in the

remote mode (or the center mode unless the remote mode is available) is displayed.

(ii) Inspection display, filter sign: Any of unit that starts initially is displayed.

(c) Confirmation of connected units

(i) In case of RC-EX3 remote control

If you touch the buttons in the order of “Menu”

→

“Service setting”

→

“Service & Maintenance”

→

“IU address”

on the TOP screen of remote control, the indoor units which are connected are displayed.

(ii) In case of RC-E5 remote control

Pressing “AIR CON No.” button on the remote control displays the indoor unit address. If “

▲

” “

▼

” button is

pressed at the next, it is displayed orderly starting from the unit of smallest No.

(d) In case of anomaly

If any anomaly occurs on a unit in a group (a protective function operates), that unit stops with the anomalous stop but

any other normal units continue to run as they are.

(e)

Signal wiring procedure

Signal wiring between indoor and outdoor units should be made on each unit same as the normal wiring. For the group

control, connect the remote control wiring to each indoor unit via terminal block for the remote control.

Connect the remote control wiring separately from the power source cable or wires of other electric devices (AC220V or

higher).

(18) High ceiling control

When sufficient air flow rate cannot be obtained from the indoor unit which is installed at a room with high ceiling, the air flow

rate can be increased by changing the fan tap. To change the fan tap, use the indoor unit function “FAN SPEED SET” on the

wired remote control.

-

-

-

-

-

-

-

STANDARD

HIGH SPEED1

[Setting 1]

[Setting 2]

HIGH SPEED2

FAN SPEED SET

Hi - ULo

Hi - Lo

Hi - Me

Hi - Me - ULo

Hi - Me - Lo

PHi2 - Hi - Me - ULo

PHi1 - Hi

PHi1 - Me

PHi1 - Hi - Me

PHi2 - PHi1 - Hi - Me

PHi2 - Hi - Me - Lo

Indoor unit airflow setting

Fan tap

Hi - Me

Notes (1) Factory default is STANDARD.

(2) At the hot-start and heating thermostat OFF, or other, the indoor fan is operated at the low speed tap of each setting.

(3) This function is not able to be set with wireless remote controls or simple remote control (RCH-E3)

(4) Values in [ ] are for the RC - EX3 models.

SW2: For setting of 0 – 9, A – F

SW5: For setting of master and slave units

(See table shown at right.)

Remote control

Indoor unit

Outdoor unit

Signal wiring

between outdoor unit

and indoor units

(Master unit)

(Slave unit a)

(Slave unit b)

Remote control wiring

R

0

1

2

3

F

4

4

4

(Slave unit c)

4

Refrigerant piping

Master unit

OFF

OFF

OFF

ON

SW5-1

SW5-2

ON

OFF

ON

ON

Slave unit a

Slave unit b

Slave unit c

Switch

Unit

SW5 setting

P2.indb 126

2/20/2017 1:08:37 PM

C

M

Y

CM

MY

CY

CMY

K

P58-1.pdf 2017/03/21 12:38:12