'17 • KX-T-254

Simple Remote Control Installation Manual

Read together with indoor unit's installation manual.

WARNING

●

Fasten the wiring to the terminal securely and hold the cable securely so as not to apply

unexpected stress on the terminal.

Loose connection or hold will cause abnormal heat generation or fire.

●

Make sure the power source is turned off when electric wiring work.

Otherwise, electric shock, malfunction and improper running may occur.

CAUTION

●

Do not leave the remote control without the upper case.

In case the upper cace needs to be detached, protect the remote control with a packaging box

or bag in order to keep it away from water and dust.

●

Do not install the remote control at the following places in order to avoid malfunction.

(1) Places exposed to direct sunlight

(4) Hot surface or cold surface enough to generate condensation

(2) Places near heat devices

(5) Places exposed to oil mist or steam directly

(3) High humidity places

(6) Uneven surface

Accessories

Remote control, wood screw (

φ

3.5

×

16) 2 pieces

Prepare on site

Remote control cord (2 cores) (Refer to [2. Installation and wiring of remote control])

[In case of embedding cord] Electrical box, M4 screw (2 pieces)

[In case of exposing cord] Cord clamp (if needed)

1.

Installation procedure

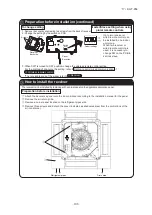

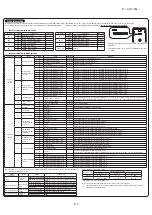

In case of embedding cord

⑴

Make certain to remove the screw on the bottom

surface of the remote control.

⑵

Remove the upper case of the remote control.

Insert a flat-blade screwdriver to a concave portion of the bottom

surface of the remote control and slightly twist it, and the case is

removed.

⑶

Pre-bury the electrical box and remote control cord.

⑷

Prepare two M4 screws (recommended length: 12 – 16mm), and install the lower case to the electrical box.

Do not use a screw whose screw head is larger than the height of the wall around the screw hole.

⑸

Connect the remote control cord to the terminal block.

Connect the terminals (X and Y) of the remote control and the terminals (X and Y) of the indoor

unit. (No polarity of X and Y)

⑹

Mount the upper case for restoring to its former state so as not to crimp the remote control cord,

and secure with the removed screw.

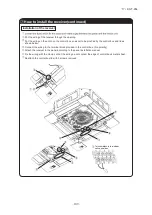

In case of exposing cord

⑴

Make certain to remove a screw on the bottom surface of the

remote control.

⑵

Remove the upper case of the remote control.

Insert a flat-blade screwdriver to a concave portion of

the bottom surface of the remote control and slightly

twist it, and the case is removed.

⑶

The remote control cord can be extracted from the

upper center.

After the thin part in the upper side of the remote

control upper case is scraped with a nipper or knife,

remove burr with a file.

⑷

The lower case of the remote control is mounted to

a flat wall with two accessory wood screws.

⑸

Connect the remote control cord to the terminal block.

Connect the terminals (X and Y) of the remote control and

the terminals (X and Y) of the indoor unit. (No polarity of X and

Y)

The wiring route is as shown in the right.

The wiring in the remote control case should be 0.3 mm

2

(recommended) to 0.5 mm

2

at

maximum.

Further, peel off the sheath.

The peeling length of each wiring is as follows:

X wiring : 160mm

Y wiring : 150mm

⑹

Mount the upper case for restoring to its former state so as not to

crimp the remote control cord, and secure with the removed screw.

⑺

In the case of exposing installation, secure the remote control cord to the wall surface with a

cord clamp so as not to loosen the remote control cord.

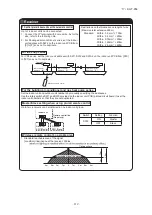

2.

Installation and wiring of remote control

⑴

Wiring of remote control should use 0.3mm

2

× 2 cores wires or cables. (on-site configuration)

⑵

Maximum prolongation of remote control wiring is 600 m.

If the prolongation is over 100m, change to the size below.

But, the wiring in the remote control case should be 0.3mm

2

(recommended) to 0.5mm

2

.

Change the wire size outside of the case according to wire connecting. Waterproof treatment is

necessary at the wire

connecting section. Be careful about contact failure.

100 - 200m

・・・・・・・・・・・・・・・・・

0.5mm

2

× 2 cores

Under 300m

・・・・・・・・・・・・・・・・・

0.75mm

2

× 2 cores

Under 400m

・・・・・・・・・・・・・・・・・

1.25mm

2

× 2 cores

Under 600m

・・・・・・・・・・・・・・・・・

2.0mm

2

× 2 cores

⑵

Set the switch SW1-1 of the slave remote control is “Slave” (ON). The factory default is set as “Master” (OFF).

(Note) • The remote control thermistor enabled setting can be set only to the master remote control.

• Install the master remote control at the position to detect room temperature.

• The air-conditioner operation follows the last operation of the remote control in case of the

master / slave setting.

3.

Master/ slave setting when more than one remote control are used

⑴

Up to two remote controls can be connected to one unit (or one group) of indoor unit.

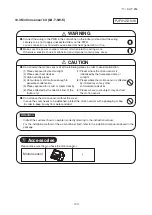

4.

The indication when power source is supplied

⑴

At the time of turning the power source on, after the light is on for the first 2 seconds, the display

becomes as shown below.

The number displayed on the upper side of LCD in the remote control is the software number,

and this is not an error code.

⑵

Then, “88.0 °C” blinks on the remote control until the communication between the remote

control and the indoor unit is established.

⑶

In the case of connecting one remote control with one unit (or one group) of indoor unit, make

certain to set the master remote control (factory default).

If the slave remote control is set, a communication cannot be

established.

⑷

If a state where the communication between the remote

control and the indoor unit cannot be established continues

about for 30 minutes, “E” is displayed. Confirm the wiring of

the indoor unit and the outdoor unit and master/slave setting of

the remote control.

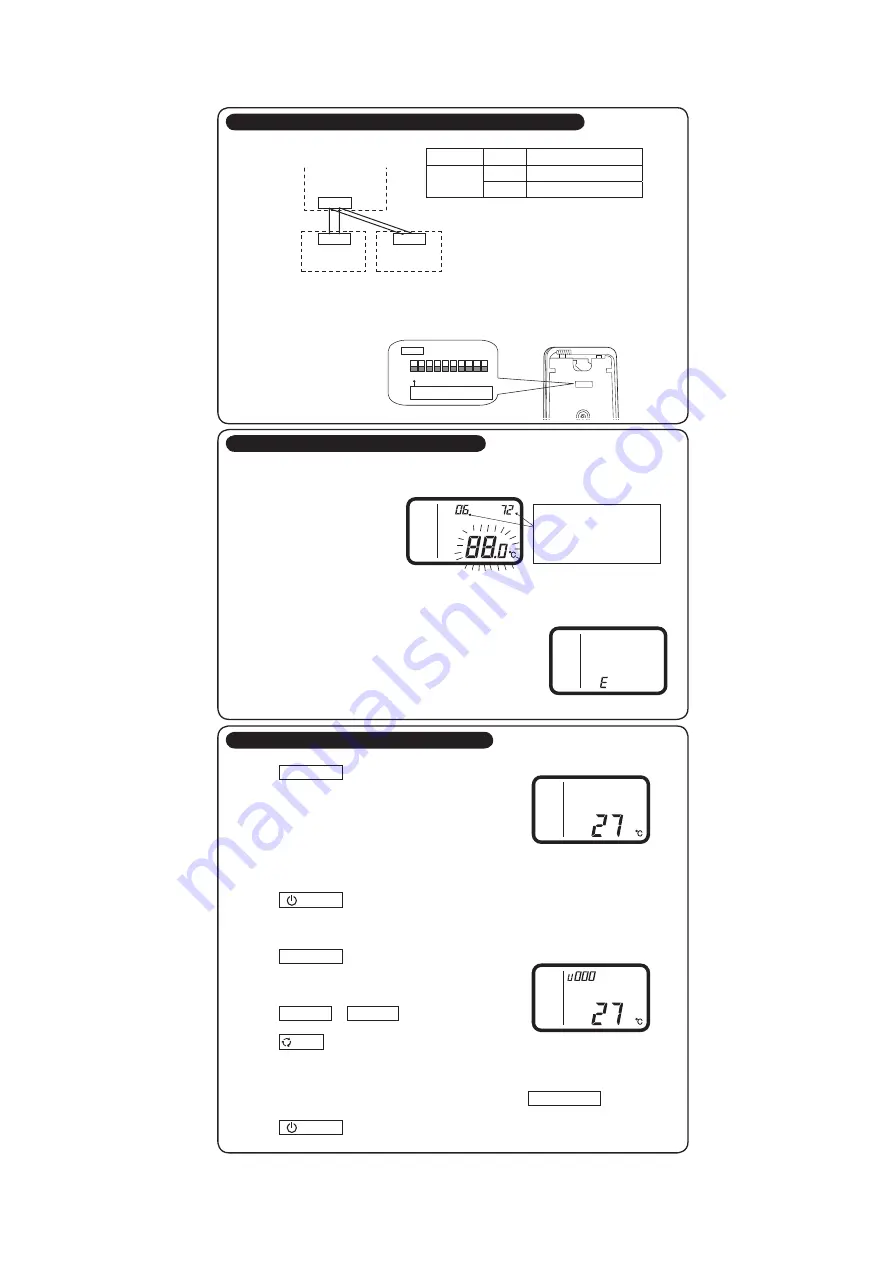

5.

Confirmation method for return air temperature

Return air temperature can be confirmed by the remote control operation.

⑴

Press AIR CON No. button for over 5 seconds.

“88” blinks on the temperature setting indicator.

(“88” blinks for approximately 2 seconds while data are read.)

↓

Then, the return air temperature is displayed.

(Example) return air temperature: “27 °C” (blinking)

(Note) For the return air temperature, in the normal case, the return air temperature of the indoor

unit is displayed; however, in the case that the remote control thermistor is effective,

detected temperature by the remote control thermistor is displayed.

⑵

Press

ON/OFF button.

End.

[In the case that the remote thermistor is ineffective and plural indoor units are connected to one

remote control ]

⑴

Press AIR CON No. button for over 5 seconds.

indoor unit No. indicator: “U 000” (blinking)

(Among the connected indoor units, the lowest

number is displayed.)

⑵

Press TEMP

△

or TEMP

▽

button.

Select the indoor unit No.

⑶

Press MODE button.

Dectder the indoor unit No.

(Example) indoor unit No. indicator: “U 000”

“88” blinks on the temperature setting indicator. (blinking for approximately 2 to 10 seconds while

data is read) Then, the return air temperature is displayed. When

is pressed, return

to the indoor unit selection display (example, “U 000”).

⑷

Press

ON/OFF button.

End.

PJZ012D069

Screw

⑴

Lower case

Wall

surface

⑷

X Y

⑸

⑶

Remote control cord

Electrical box

Prepare on site

Two M4 screws (head: ø8 or less) (prepare on site)

⑷

Screw

⑴

Sheath

Peeling length

Remote control line (No polarity)

○

X ○

Y

Remote control “Master”

SW1-1 “OFF”

indoor unit

○

X ○

Y

○

X ○

Y

Switch

Setting

Function detail

Slave remote control

Master remote control

ON

SW1-1

OFF

Remote control “Slave”

SW1-1 “ON”

Software number

(The number in the left is one

example. Another number

may be shown.)

Wiring outlet

Lower case

⑵

Upper case

⑵

Upper case

⑶

Thin part

1

SW1

SW1-1:ON (Slave remote control)

SW1-1:OFF(Master remote control)

ON

OFF

2 3 4 5 6 7 8 9 0

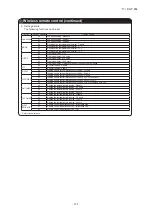

6.

Function setting

Each function of the remote control and the indoor unit is automatically set to the initial setting, which is the standard use, on the occasion of connecting the remote control with the indoor unit. In the case of the standard

use, the setting change is unnecessary. However, if you whould like to change the initial setting “

○

”, change the setting for only the item of the function number.

Record the setting contents and stored them.

⑴

Function setting item by switch on PCB

Switch No.

Setting

Setting detail

Initial setting

SW1-1

ON

Slave remote control

OFF

Master remote control

○

SW1-2

ON

Remote control thermistor enabled

OFF

Remote control thermistor disabled

○

SW1-3

ON

“MODE” button prohibited

OFF

“MODE” button enabled

○

SW1-4

ON

“ON/OFF” button prohibited

OFF

“ON/OFF” button enabled

○

⑵

Function setting item by button operation

Note 1: The symbol “

※

” in the initial setting varies depending upon the indoor unit and the outdoor unit to be connected, and this is

automatically determined as follows:

Swith No.

Function No.

Function

Setting

Product model

SW1-6

“FAN SPEED”

button

“FAN SPEED” button prohibited Product model whose indoor fan speed is only one step

“FAN SPEED” button enabled Product model whose indoor fan speed is two steps or three

steps

Remote control function 01

Indoor unit fan

speed

Fan speed: three steps

Product model whose indoor unit fan speed is three steps

Fan speed: two steps (Hi-Lo) Product model whose indoor unit fan speed is two steps

Fan speed: two steps (Hi-Me)

Fan: one step

Product model whose indoor unit fan speed is only one step

Remote control function 06

“Auto” operation

setting

“Auto” operation enabled

Product model where “Auto” mode is selectable

“Auto” operation disabled

Product model without “Auto” mode

Indoor unit function 13

Heating fan

control

Low fan speed

Product model except FDUS

Intermittent operation

FDUS

Classification

Function No.

Function

Setting No.

Setting

Initial setting

Remarks

Remote

control

function

01

Indoor unit fan speed

01

Fan speed: three steps

※

Note 1 The fan speed is three steps,

-

-

.

02

Fan speed: two steps (Hi-Lo)

※

Note 1 The fan speed is two steps,

-

.

03

Fan speed: two steps (Hi-Me)

The fan speed is two steps,

-

.

04

Fan: one step

※

Note 1 The fan speed is fixed to one step.

03

Remote control

thermistor at the time

of cooling

01

Remote control thermistor: no offset

○

02

Remote control thermistor: +3.0 °C

At the time of cooling, in the case of remote control thermistor enabled, offset temperature at +3.0°C.

03

Remote control thermistor: +2.0 °C

At the time of cooling, in the case of remote control thermistor enabled, offset temperature at +2.0°C.

04

Remote control thermistor: +1.0 °C

At the time of cooling, in the case of remote control thermistor enabled, offset temperature at +1.0°C.

05

Remote control thermistor: -1.0 °C

At the time of cooling, in the case of remote control thermistor enabled, offset temperature at -1.0°C.

06

Remote control thermistor: -2.0 °C

At the time of cooling, in the case of remote control thermistor enabled, offset temperature at -2.0°C.

07

Remote control thermistor: -3.0 °C

At the time of cooling, in the case of remote control thermistor enabled, offsett temperature at -3.0°C.

04

Remote control

thermistor at the time

of heating

01

Remote control thermistor: no offset

○

02

Remote control thermistor: +3.0 °C

At the time of heating, in the case of remote control thermistor enabled, offset temperature at +3.0°C.

03

Remote control thermistor: +2.0 °C

At the time of heating, in the case of remote control thermistor enabled, offset temperature at +2.0°C.

04

Remote control thermistor: +1.0 °C

At the time of heating, in the case of remote control thermistor enabled, offset temperature at +1.0°C.

05

Remote control thermistor: -1.0 °C

At the time of heating, in the case of remote control thermistor enabled, offset temperature at -1.0°C.

06

Remote control thermistor: -2.0 °C

At the time of heating, in the case of remote control thermistor enabled, offset temperature at -2.0°C.

07

Remote control thermistor: -3.0 °C

At the time of heating, in the case of remote control thermistor enabled, offset temperature at -3.0°C.

05

Ventilation setting

01

No ventilator connection

○

02

Ventilator links air-conditioner

In case of Single split series, by connecting ventilation device to CnT of the indoor printed circuit board (in case of VRF series, by

connecting it to CND of the indoor printed circuit board), the operation of ventilation device is linked with the operation of indoor unit.

06

“Auto” operation

setting

01

“Auto” operation enabled

※

Note 1

02

“Auto” operation disabled

※

Note 1 “Auto” operation disabled

Indoor unit

function

07

Operation permission/

prohibition

01

Disabled

○

02

Enabled

Operation permission/prohibition control is enabled.

08

External input

01

Level input

○

02

Pulse input

09

Fan speed setting

01

Standard

Note2

02

High speed 1

Note2

03

High speed 2

Note2

10

Fan remaining

operation at the time

of cooling

01

No remaining operation

○

After cooling stopped, no fan remaining operation

02

0.5 hours

After cooling stopped, fan remaining operation for 0.5 hours

03

1 hour

After cooling stopped, fan remaining operation for 1 hour

04

6 hours

After cooling stopped, fan remaining operation for 6 hours

11

Fan remaining

operation at the time

of heating

01

No remaining operation

○

After heating stopped or after heating thermostat OFF, no fan remaining operation

02

0.5 hours

After heating stopped or after heating thermostat OFF, fan remaining operation for 0.5 hours

03

2 hours

After heating stopped or after heating thermostat OFF, fan remaining operation for 2 hours

04

6 hours

After heating stopped or after heating thermostat OFF, fan remaining operation for 6 hours

12

Setting temperature

offset at the time of

heating

01

No offset

○

02

Setting temperature 3.0 °C

The setting temperature at the time of heating is offset by +3.0 °C.

03

Setting temperature 2.0 °C

The setting temperature at the time of heating is offset by +2.0 °C.

04

Setting temperature 1.0 °C

The setting temperature at the time of heating is offset by +1.0 °C.

13

Heating fan controller

01

Low fan speed

※

Note 1 At the time of heating thermostat OFF, operate with low fan speed.

02

Setting fan speed

At the time of heating thermostat OFF, operate with the setting fan speed.

03

Intermittent operation

※

Note 1 At the time of heatingr thermostat OFF, intermittently operate.

04

Fan off

At the time of heating thermostat OFF, a fan will be stopped.

When the remote control thermistor is enabled, automatically set to “Fan off”. Do not set at the time of the indoor unit thermistor.

14

Return air temperature

offset

01

No offset

○

02

Return air temperature 2.0 °C

Offset the return air temperature of the indoor unit by +2.0 °C.

03

Return air temperature 1.5 °C

Offset the return air temperature of the indoor unit by +1.5 °C.

04

Return air temperature 1.0 °C

Offset the return air temperature of the indoor unit by +1.0 °C.

05

Return air temperature offset -1.0 °C

Offset the return air temperature of the indoor unit by -1.0 °C.

06

Return air temperature offset -1.5 °C

Offset the return air temperature of the indoor unit by -1.5 °C.

07

Return air temperature offset -2.0 °C

Offset the return air temperature of the indoor unit by -2.0 °C.

[In the case of selecting the indoor unit function (07-14)]

①

“88” blinks on the temperature setting indicators.

(blinking for approximately 2 to 10 seconds while data are read)

↓

After that, the current setting number of the selected function number blinks.

(Example)

Function number: “07” (lighting)

Setting number: “01” (blinking)

Proceed to

②

.

[Note]

a.

In the case of connecting one remote control to plural indoor units, the display

will be as follows:

Indoor unit No. display: “U 000” (blinking)

(Display the lowest number among the connected indoor units.)

b.

Press TEMP

△

or TEMP

▽

button.

Select the indoor unit No. to be set.

If “U ALL” is selected, the same setting can be set to all units.

c.

Press

MODE button.

Decide the indoor unit No.

“88” blinks on the temperature setting indicators. (blinking for 2 to 10 seconds while data

are read)

When

button is pressed, go back to the indoor unit selection display (for

example, “U 000” blinking).

②

Press TEMP

△

or TEMP

▽

button.

Select the setting number

③

Press

MODE button.

The setting is completed.

Light is on for approximately 3 to 20 seconds while data of the decided function No. and

setting No. is transmitted.

(Example)

Indoor unit No.: “U 000” (lighting for 3 to 20 seconds)

Function number: “07” (lighting for 3 to 20 seconds)

Setting number: “01” (lighting for 3 to 20 seconds)

Then, the screen goes back to the function number blinking indication

⑴

, if the setting

is sequentially conducted, continue with the same procedures. If the setting is finished,

proceed to

⑸

.

⑴

Stop air-conditioning, and simultaneously press AIR CON No. and

MODE buttons

at the same time for over three seconds.

The function number “01” blinks in the upper right.

⑵

Press TEMP

△

or TEMP

▽

button.

Select the function number.

⑶

Press

MODE button.

Decide the function number.

⑷

[In the case of selecting the remote control function (01-06)]

①

The current setting number of the selected function number blinks

(Example)

Function number: “01” (lighting)

Setting number: “01” (blinking)

②

Press TEMP

△

or TEMP

▽

button.

Select the setting number.

③

Press

MODE button.

The setting is completed.

Light is on for approximately 3 to 20 seconds while data of the

decided function No. and setting No. is transmitted.

(Example)

Function number: “01” (lighting for 3 to 20 seconds)

Setting number: “01” (lighting for 3 to 20 seconds)

Then, the screen goes back to the function number blinking

indication

⑴

, if the setting is sequentially conducted, continue

with the same procedures. If the setting is finished, proceed to

⑸

.

⑸

Press

ON/OFF button.

The setting is completed.

Function number

Function number

Setting number

Function number

Setting number

Function number

Setting number

Function number

Indoor unit No.

Indoor unit No.

(In the case of

connecting

plural indoor

units)

Function number

Setting number

1

SW1

ON

OFF

2 3 4 5 6 7 8 9 0

• As for the slave remote control, function setting is impossible other

than SW1-1.

•

In the indoor unit with only one fan speed, “FAN SPEED” button cannot

be enabled.

・

Even if

button is pressed during setting, the setting is ended. However, any details where the setting has not been completed will be ineffective.

・

The setting contents are stored in the controller, and even if the power failure

occur, this will not be lost.

[Confirmation method for current setting]

According to the operation, the “setting number” displayed first after selecting “function number” and pressing

MODE button is the currently set content.

(However, in the case of selecting “U ALL” (all units), the setting number of the lowest number among the indoor units is displayed.)

Decide button

Start button

Select button

End button

Note 3: As for plural indoor unit, set indoor functions to each master and slave indoor unit.

But only master indoor unit is received the setting change of indoor unit function “07 Operation permission/

prohibition” and “08 External input”.

Note 2: Fan speed of “High speed” setting

Fan speed setting

Indoor unit fan speed setting

-

-

-

-

Standard

Hi

-

Mid

-

Lo

Hi

-

Lo

Hi

-

Mid

High speed 1

・

2

UHi

-

Hi

-

Mid

UHi

-

Mid

UHi

-

Hi

Initial setting of some indoor unit is “High speed”.

7.

How to set functions by button operation

Switch No.

Setting

Setting detail

Initial setting

SW1-5

ON

“TEMP” button prohibited

OFF

“TEMP” button enabled

○

SW1-6

ON

“FAN SPEED” button prohibited

※

Note 1

OFF

“FAN SPEED” button enabled

※

Note 1

SW1-7

ON

Auto restart function enabled

OFF

Auto restart function disabled

○

SW1-8, 9, 0

ON

Not used

OFF

PJZ012D069.indd 1

2008/11/13 11:42:01

AIR CON No.

AIR CON No.

ON/OFF

–

117

–