–

31

–

'17 • KX-T-254

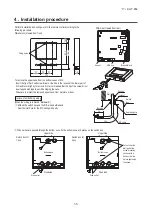

Address setting is done by (1) Manual address setting or (2) Automatic address setting.

In the case of (2) "Automatic address setting", it is possible to change address setting by wired

remote control after once complete setting.

As for details of setting procedure, refer to instructions attached to the outdoor unit for details.

②

Address setting

Ⓧ Ⓨ

Ⓧ Ⓨ

Ⓧ Ⓨ

Ⓐ Ⓑ

Ⓐ Ⓑ

Ⓧ Ⓨ

Ⓐ Ⓑ

Ⓐ Ⓑ

Ⓧ Ⓨ

Ⓐ Ⓑ

Ⓧ Ⓨ

Ⓐ Ⓑ

Ⓧ Ⓨ

Ⓐ Ⓑ

Ⓧ Ⓨ

Ⓐ Ⓑ

Ⓧ Ⓨ

Ⓧ Ⓨ

①

A remote control can control plural indoor units (up to 16)

In above setting, all plural indoor units will operate under same mode and temperature setting.

②

Connect all indoor units with 2 cores remote control line for group control.

③

Use the function of manual address setting to set the indoor and outdoor address number.

○

Do not forget to set the number for the outdoor units.

④

As shown in the following figure, the remote control can be used to control multiple outdoor

units.

⑤

One remote control is able to perform group control for multiple units (maximum 16 units).

○

Use the rotary SW1 and SW2 provided on the indoor unit PCB (Printed circuit board) to set unique remote control

communication address avoiding duplication.

Outdoor unit

No.01

Outdoor unit

No.02

Indoor unit

Indoor unit

Outdoor No.01

Indoor No.01

Indoor unit

Indoor unit

Indoor unit

Indoor unit

Remote control

Indoor unit

Remote control

SW1” Master”

Remote control

SW1” Slave”

Switch Setting Contents

Master

Slave

Slave remote

control

Wired remote control: SW1

Wireless kit: SW1-2

Master remote

control

Outdoor No.02

Indoor No.04

Outdoor No.01

Indoor No.02

Outdoor No.02

Indoor No.05

Outdoor No.01

Indoor No.03

Outdoor No.02

Indoor No.06

●

Do not install it on the following places.

(1) Place exposed to direct sunlight

(4) Hot surface or cold surface enough to generate condensation

(2) Places near heat devices

(5) Place exposed to oil mist or steam directly.

(3) High humidity places

(6) Uneven surface

③

Remote Control, Wiring and functions

①

Install remote control referring to the attached manual.

②

Wiring of remote control should use 0.3mm

2

x2 cores wires or cables.

The insulation thickness is 1mm or more. (on-site configuration)

③

Maximum prolongation of remote control wiring is 600 m.

If the prolongation is over 100m, change to the size below.

But, wiring in the remote control case should be under 0.5mm

2

. Change the wire size outside of the case

according to wire connecting. Waterproof treatment is necessary at the wire connecting section. Be careful about

contact failure.

100-200m ...................0.5mm

2

×2 cores

Under 300m................0.75mm

2

× 2 cores

Under 400m................1.25mm

2

× 2 cores

Under 500m................2.0mm

2

× 2 cores

④

Avoid using multi-core cables to prevent malfunction.

⑤

Keep remote control line away from earth (frame or any metal of building).

⑥

Make sure to connect remote control line to the remote control and terminal block of

indoor unit. (No polarity)

Remote control line

(No polarity)

Remote control line

(No polarity)

Installation and wiring of remote control

Control plural indoor units by a single remote control

A maximum of two remote control units can be connected to one indoor unit (or one group of

indoor units.)

Latest "function setting" is superior than previous one.

Acceptable combination is "two (2) wired remote controls", "one (1) wired remote control and

one (1) wireless kit" or "two (2) wireless kits".

Set one to “Master” and the other to “Slave”.

Note:The setting "Remote control unit sensor enabled" is only selectable with the master

remote control unit in the position where you want to check room temperature.

Master/slave setting when more than one remote control unit are used

③④

Operation and confirmation from remote control

⑤

Function of CnT connector of indoor printed circuit board

●

X

R1-4

are DC 12 V relays. (Equivalent to Omron’s LY2F)

●

X

R5

is a DC 12 V, 24 V or 100 V relay. (Equivalent to Omron’s MY2F)

●

Maker and model of CnT connector (Site side)

Connector : Molex 5264-06

Terminal : Molex 5263T

●

CnTA connector is used on FDT, or other. <Check with the specifications.> (Site side) Maker

and model

Connector : J.S.T. Mfg. XAP02V-1-E

Terminal : J.S.T. Mfg. SXA-01T-P0.6

●

Output 1 – 4 and input1/2 can be selected/set as required from following items.

Factory default is set as shown below.

1

2

1

2

CNT

(Blue/6P)

+12

CNTA

(Blue/2P)

+12

Indoor PCB

X

R1

X

R1

X

R2

X

R3

X

R4

X

R2

X

R3

X

R4

X

R5

Common

Output 1

Output 2

Output 3

Output 4

Remote ON/OFF switch

or timer contactor

AC100V/1200V

DC12V

DC24V

Input 1

X

R6

AC100V/1200V

DC12V

DC24V

Input 2

Note (1) 0.3 mm

2

× 2 m

Note (1) 0.3 mm

2

× 2 m

Note (1) To be no longer than 2 m.

0.75mm

2

× 0.2 m

Butt-connecting contactor

Red

Black

Yellow

Blue

Brown

Orange

Remote ON-OFF/monitor kit

(Applicable range: 0.75 – 1.25 mm

2

)

X

R5

X

R6

White

Black

Yellow

Blue

Brown

Orange

Orange

●

For the setting method, refer to the technical data.

Output

Input

Factory default setting

①

②

③

④

⑤

⑥

⑦

⑧

RUN/STOP

RUN permit prohibition

Emergency stop

Cooling/Heating

Setting temp. shift

Compulsory thermostat OFF

Temporary stop

Silent mode

CnT-2

CnT-3

CnT-4

CnT-5

CnT-6

CnTA

RUN output

Heating output

Compressor ON output

Inspection (error) output

RUN/STOP

RUN/STOP

Output 1

Output 2

Output 3

Output 4

Input 1

Input 2

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

RUN output

Heating output

Compressor ON output

Inspection (error) output

Cooling output

Fan ON output 1

Fan ON output 2

Fan ON output 3

Defrost/oil return output

Ventilation output

Heater output

Free cleaning output

Indoor overload error output

1

2

3

4

5

6

1

2

3

4

5

6

No.

Item

Operation from the eco touch remote

control (RC-EX3)

Operation from the standard remote control

(RC-E4, RC-E5)

1 Check the number

of units connected

in the multi remote

control system.

[Menu]

⇒

[Service setting]

⇒

[Service & Maintenance]

⇒

[Service password]

⇒

[IU address]

①

Press the

AIR CON NO.

CHECK

TEST

TEST

button to display

the IU address.

②

Press the

AIR CON NO.

CHECK

TEST

TEST

or

AIR CON NO.

CHECK

TEST

TEST

button and check

addresses of connected indoor units one

by one.

2 Check if each unit is

connected properly

in the remote

control system.

[Menu]

⇒

[Service setting]

⇒

[Service & Maintenance]

⇒

[Service password]

⇒

[IU address]

⇒

[Check run mode]

①

Press the

AIR CON NO.

CHECK

TEST

TEST

button to display

the IU address.

②

Press the

AIR CON NO.

CHECK

TEST

TEST

or

AIR CON NO.

CHECK

TEST

TEST

button and select one

of IU addresses.

③

Press the

AIR CON NO.

CHECK

TEST

TEST

(MODE) button. The unit

starts to blow air.

3 Setting main/sub

remote controls

[Menu]

⇒

[Service setting]

⇒

[R/C function settings]

⇒

[Service password]

⇒

[Main/Sub of R/C]

Set SW1 to “Sub” for the sub remote control

unit.

4 Checking operation

data

[Menu]

⇒

[Service setting]

⇒

[Service & Maintenance]

⇒

[Service password]

⇒

[Operation data]

Press the

AIR CON NO.

CHECK

TEST

TEST

button.

⇒

“

AIR CON NO.

CHECK

TEST

TEST

”

is displayed.

⇒

Press the

AIR CON NO.

CHECK

TEST

TEST

(SET) button.

⇒

“

AIR CON NO.

CHECK

TEST

TEST

” is displayed.

⇒

Select one

of addresses for connected indoor units

by pressing the

AIR CON NO.

CHECK

TEST

TEST

or

AIR CON NO.

CHECK

TEST

TEST

button.

⇒

Press

the

AIR CON NO.

CHECK

TEST

TEST

(SET) button.

⇒

“

AIR CON NO.

CHECK

TEST

TEST

” is

displayed.

⇒

Select data by pressing the

AIR CON NO.

CHECK

TEST

TEST

or

AIR CON NO.

CHECK

TEST

TEST

button.

5 Checking inspection

display

[Menu]

⇒

[Service setting]

⇒

[Service & Maintenance]

⇒

[Service password]

⇒

[Error display]

Press the

AIR CON NO.

CHECK

TEST

TEST

button.

⇒

“

AIR CON NO.

CHECK

TEST

TEST

” is

displayed.

⇒

Press the

AIR CON NO.

CHECK

TEST

TEST

button.

⇒

“

AIR CON NO.

CHECK

TEST

TEST

” is displayed.

⇒

Press

the

AIR CON NO.

CHECK

TEST

TEST

(SET) button.

⇒

“

AIR CON NO.

CHECK

TEST

TEST

” is

displayed.

⇒

Data is displayed.

6 Cooling test run

from remote control

[Menu]

⇒

[Service setting]

⇒

[Installation settings]

⇒

[Service password]

⇒

[Test run]

⇒

[Cooling test run]

⇒

[Start]

①

Start the system by pressing the

AIR CON NO.

CHECK

TEST

TEST

button.

②

Select “

AIR CON NO.

CHECK

TEST

TEST

(Cool)” with the

AIR CON NO.

CHECK

TEST

TEST

(MODE)

button.

③

Press the

AIR CON NO.

CHECK

TEST

TEST

button for 3 seconds or

longer. The screen display will switch to

“

AIR CON NO.

CHECK

TEST

TEST

”.

④

Pressing the

AIR CON NO.

CHECK

TEST

TEST

(SET) button, while the

“

AIR CON NO.

CHECK

TEST

TEST

” is displayed, starts the

cooling test run. The screen display will

switch to “

AIR CON NO.

CHECK

TEST

TEST

”.

7 Trial operation of

drain pump from

remote control

[Menu]

⇒

[Service setting]

⇒

[Installation settings]

⇒

[Service password]

⇒

[Test run]

⇒

[Drain pump test run]

⇒

[Run]

①

Start the system by pressing the

AIR CON NO.

CHECK

TEST

TEST

button. The display will change

to “

AIR CON NO.

CHECK

TEST

TEST

”.

②

Press the

AIR CON NO.

CHECK

TEST

TEST

button once to display

“

AIR CON NO.

CHECK

TEST

TEST

”.

③

Pressing the

AIR CON NO.

CHECK

TEST

TEST

(SET) button starts the

drain pump operation. The display will

show “

AIR CON NO.

CHECK

TEST

TEST

”.

The menu configuration may vary depending on models of the remote control. If the model of your remote

control is different, refer to the installation manual attached to the remote control.