'14 • KX-T-222

'14 • KX-T-222

CONTENTS

1. SPECIFICATIONS ............................................................................................. 1

1.1 Duct connected-High static pressure type (FDU).......................................... 1

1.2 Outdoor air processing unit (FDU-F)............................................................. 2

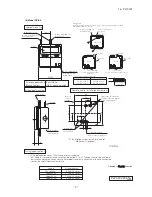

2. EXTERIOR DIMENSIONS ................................................................................. 3

2.1 Indoor unit ..................................................................................................... 3

8

9

(1) Duct connected-High static pressure type (FDU) ..................................

10

18

18

18

13

13

14

25

25

(2) Outdoor air processing unit (FDU-F)......................................................

35

2.2 Wired remote control (option parts) .............................................................

39

52

52

7. APPLICATION DATA......................................................................................

7.1 Installation manual for indoor unit ...............................................................

(1) Model RC-EX1A ....................................................................................

(2) Model RC-E5 .........................................................................................

3. ELECTRICAL WIRING ......................................................................................

3.1 Duct connected-High static pressure type (FDU)..........................................

3.2 Outdoor air processing unit (FDU-F)...........................................................

5. NOISE LEVEL .................................................................................................

5.1 Duct connected-High static pressure type (FDU)

5.2 Outdoor air processing unit (FDU-F)

4. CHARACTERISTICS OF FAN ........................................................................

4.1 Duct connected-High static pressure type (FDU)

4.2 Outdoor air processing unit (FDU-F)

........................................

...........................................................

........................................

...........................................................

7.2 Electric wiring work instruction ....................................................................

7.3 Installation manual for wired remote control (option parts) ........................

8. OUTLINE OF OPERATION CONTROL BY MYCROCOMPUTER .................

8.1 Remote control (option parts) .....................................................................

8.2 Operation control function by the wired remote control ..............................

3

4

7

7

9

(1) Models FDU224KXZE1, 280KXZE1

Models FDU1800FKXZE1, 2400FKXZE1............................................

(2) Models FDU650FKXZE1, 1100FKXZE1..............................................

(1) Model RC-EX1A ..................................................................................

(2) Model RC-E5 ....................................................................................... 47

39

30

25

19

19

21

6. CAPACITY TABLE ..........................................................................................

6.1 Duct connected-High static pressure type (FDU)

6.2 Outdoor air processing unit (FDU-F)

........................................

...........................................................

58

8.3 Operation control function by the indoor control .........................................

73

73

74

9. SYSTEM TROUBLESHOOTING PROCEDURE .............................................

9.1 Basics of troubleshooting ............................................................................

9.2 Contents of troubleshooting ........................................................................

104

9.3 Instruction of how to replace PCB .............................................................

(1) Control PCB

(3) Fan motor control PCB ...................................................................... 108

109

9.4 Indoor PCB setting ...................................................................................

55

.......................................................................................

(2) Power PCB ........................................................................................ 106

104

110

10. OPTION PARTS

110

10.1 Wireless kit (RCN-KIT3-E) ..................................................................................

........................................................... 116

10.2 Simple wired remote control (RCH-E3)

.............................................................................................