-

181

-

'10 • KX-SM-148

Installation manual for wired remote controller

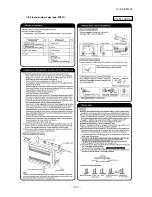

Installation and wiring of remote controller

Wiring of remote controller should use 0.3mm

2

2 core wires or cables. (on-site configuration)

Maximum prolongation of remote controller wiring is 600 m.

100 - 200m.........................0.5mm

2

2 cores

Under 300m.......................0.75mm

2

2 cores

Under 400m.......................1.25mm

2

2 cores

Under 500m.......................2.0mm

2

2 cores

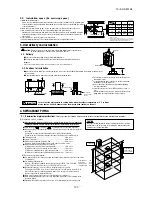

Master/ slave setting when more than one remote controllers are used

A maximum of two remote controllers can be connected to one indoor unit (or one group of indoor units.)

Remote controller cord (no polarity)

Remote controller

SW1 "Master"

Switch

Setting

Contents

M

Master remote controller

SW1

S

Slave remote controller

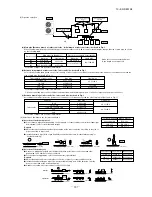

The indication when power source is supplied

When power source is turned on, the following is displayed on the remote controller until the

communication between the remote controller and indoor unit settled.

Master remote controller : " "

Slave remote controller : " "

At the same time, a mark or a number will be displayed for two seconds first.

This is the software's administration number of the remote controller, not an error cord.

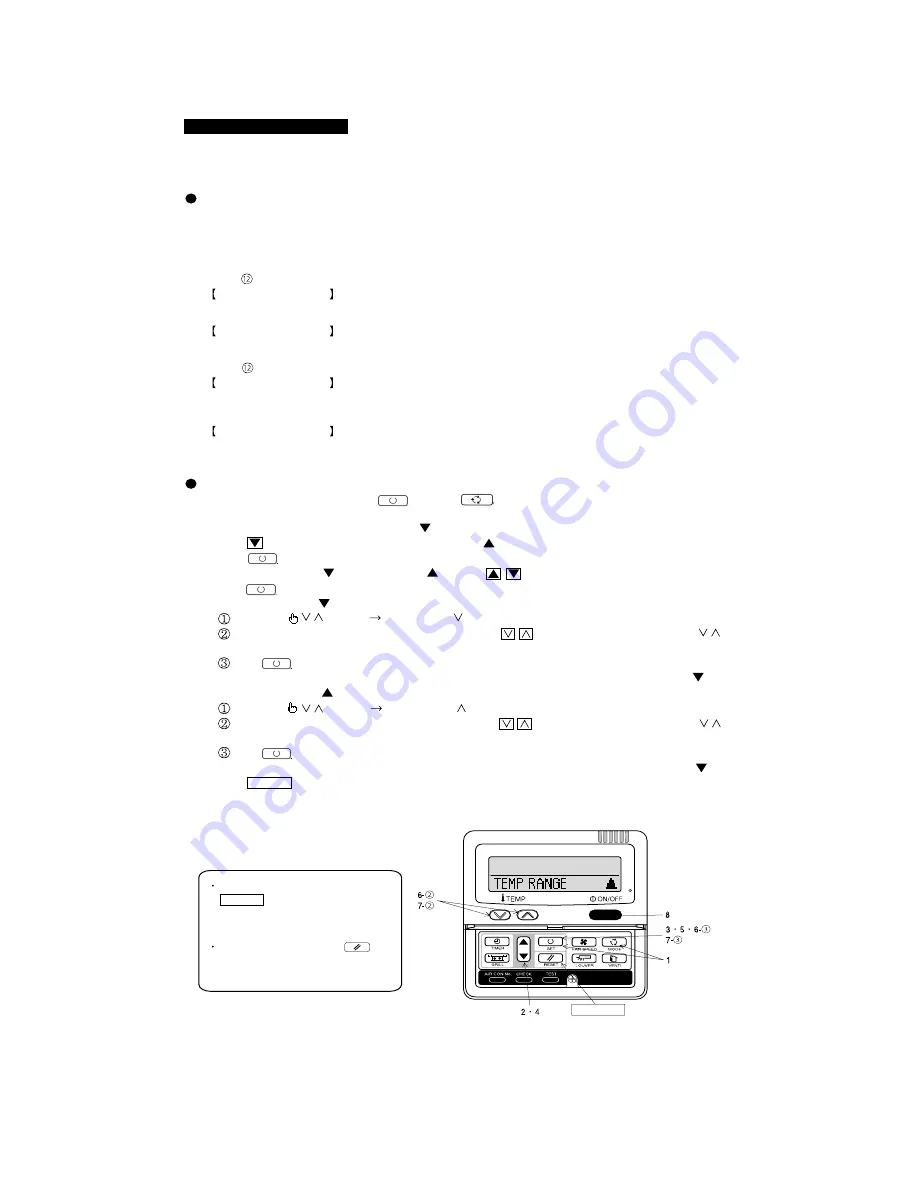

The range of temperature setting

When shipped, the range of set temperature differs depending on the operation mode as below.

Heating : 16~30˚C (55~86˚F)

Except heating (cooling, fan, dry, automatic) : 18~30˚C (62~86˚F)

Upper limit and lower limit of set temperature can be changed with remote controller.

Upper limit setting: valid during heating operation. Possible to set in the range of 20 to 30˚C (68 to 86˚F).

Lower limit setting: valid except heating (automatic, cooling, fan, dry) Possible to set in the range of 18 to 26˚C (62 to

79˚F).

When you set upper and lower limit by this function, control as below.

1. When TEMP RANGE SET, remote controller function of function setting mode is "INDN CHANGE" (factory setting),

During heating, you cannot set the value exceeding the upper limit.

During operation mode except heating, you cannot set the value below the lower limit.

2. When TEMP RANGE SET, remote controller function of function setting mode is "NO INDN CHANGE"

During heating, even if the value exceeding the upper limit is set, upper limit value will be sent to the indoor unit.

But, the indication is the same as the temperature set.

During except heating, even if the value lower than the lower limit is set, lower limit value will be sent to the indoor unit.

But, the indication is the same as the temperature set.

How to set upper and lower limit value

1. Stop the air-conditioner, and press (SET) and (MODE) button at the same time for over three

seconds .

The indication changes to "FUNCTION SET ".

2. Press button once, and change to the "TEMP RANGE " indication.

3. Press (SET) button, and enter the temperature range setting mode.

4. Select "UPPER LIMIT " or "LOWER LIMIT " by using button.

5. Press (SET) button to fix.

6. When "UPPER LIMIT " is selected (valid during heating)

Press (SET) button to fix. Indication example: "UPPER 26˚C" (Displayed for two seconds)

After the fixed upper limit value displayed for two seconds, the indication will return to "UPPER LIMIT ".

7. When "LOWER LIMIT " is selected (valid during cooling, dry, fan, automatic)

Indication: " SET UP" "LOWER 18˚C "

8. Press ON/OFF button to finish.

PJA012D729A

When remote controller cannot communicate with the indoor unit for half an hour, the below indication will

appear.

Check wiring of the indoor unit and the outdoor unit etc.

Read together with indoor unit's installation manual.

Accessories

Remote controller, wood screw (ø3.5 16) 2 pieces

Prepare on site

Remote controller cord (2 cores) the insulated thickness in 1mm or more.

[In case of embedding cord] Erectrical box, M4 screw (2 pieces)

[In case of exposing cord] Cord clamp (if needed)

Screw

Installation procedure

Open the cover of remote controller , and remove the screw under the

buttons without fail.

Remove the upper case of remote controller.

Insert a flat-blade screwdriver into the dented part of the upper part

of the remote controller, and wrench slightly.

[In case of embedding cord]

Embed the erectrical box and remote controller cord beforehand.

Prepare two M4 screws (recommended length is 12-16mm) on site, and install the lower case to erectrical box.

Choose either of the following two positions in fixing it with screws.

Connect the remote controller cord to the terminal block.

Connect the terminal of remote controller (X,Y) with the terminal of

indoor unit (X,Y). (X and Y are no polarity)

Install the upper case as before so as not to catch up the remote controller cord,

and tighten with the screws.

[In case of exposing cord]

You can pull out the remote controller cord from left upper part or center upper part.

Cut off the upper thin part of remote controller lower case with a nipper or knife,

and grind burrs with a file etc.

Install the lower case to the flat wall with attached two wooden screws.

Connect the remote controller cord to the

terminal block.

Connect the terminal of remote controller (X,Y)

with the terminal of indoor unit (X,Y).

(X and Y are no polarity)

Wiring route is as shown in the right diagram

depending on the pulling out direction.

The wiring inside the remote controller case should be within 0.3mm

2

(recommended) to 0.5mm

2

.

The sheath should be peeled off inside the remote controller case.

The peeling-off length of each wire is as below.

Pulling out from upper left Pulling out from upper center

X wiring : 215mm

Y wiring : 195mm

X wiring : 170mm

Y wiring : 190mm

Install the upper case as before so as not to catch up the remote controller cord, and tighten with

the screws.

In case of exposing cord, fix the cord on the wall with cord clamp so as not to slack.

In case of pulling out from

upper left

In case of pulling out from

upper center

The peeling-off length

of sheath

WARNING

CAUTION

Fasten the wiring to the terminal securely and hold the cable securely so as not to apply unexpected stress on the

terminal.

Loose connection or hold will cause abnormal heat generation or fire.

Make sure the power supply is turned off when electric wiring work.

Otherwise, electric shock, malfunction and improper running may occur.

DO NOT install the remote controller at the following places in order to avoid malfunction.

DO NOT leave the remote controller without the upper case.

(1) Places exposed to direct sunlight

(2) Places near heat devices

(3) High humidity places

In case the upper cace needs to be detached, protect the remote controller with a packaging box or bag in

order to keep it away from water and dust.

(4) Hot surface or cold surface enough to generate condensation

(5) Places exposed to oil mist or steam directly

(6) Uneven surface

Tighten the screws after

cutting off the thin part of

screw mounting part.

Controller cord

Erectrical box

(Prepare on site)

Lower part

Lower part

Upper part

Lower case

Lower case

Wiring oulet

Wiring oulet

M4 screw 2 (Prepare on site)

The thin part

Wiring

Wiring

Upper

Upper

Sheath

Upper case

Upper case

Board

Board

Lower

Lower

If the prolongation is over 100m, change to the size below.

But, wiring in the remote controller case should be under 0.5mm

2

. Change the wire size outside

of the case according to wire connecting. Waterproof treatment is necessary at the wire

connecting section. Be careful about contact failure.

Remote controller

SW1 "Slave"

Lower

Master

Slave

Upper

Board

The left mark is only an

example. Other marks may

appear.

Previous button

Upper part

Lower

Lower case

Upper

Lower

Lower case

Upper

Sheath

If upper limit value is set

If upper limit value is set

If lower limit value is set

If lower limit value is set

Indication: " SET UP" "UPPER 30˚C "

Select the upper limit value with temperature setting button . Indication example: "UPPER 26˚C "

(blinking)

Select the lower limit value with temperature setting button . Indication example: "LOWER 24˚C "

(blinking)

Press (SET) button to fix. Indication for example: "LOWER 24˚C" (Displayed for two seconds)

After the fixed lower limit value displayed for two seconds, the indication will return to "LOWER LIMIT ".

It is possible to finish by pressing

ON/OFF button on the way, but

unfinished change of setting is

unavailable.

During setting, if you press

(RESET) button, you return to the

previous screen.

Indoor units

Set SW1 to "Slave" for the slave remote controller. It was factory set to "Master" for shipment.

Note: The setting "Remote controller thermistor enabled" is only selectable with the master remote

controller in the position where you want to check room temperature.

The air conditioner operation follows the last operation of the remote controller regardless of the

master/ slave setting of it.

Summary of Contents for KX6 series

Page 106: ... 104 10 KX SM 148 Models FDC335KXE6M FDCS335KXE6M PCB003Z185 ...

Page 108: ... 106 10 KX SM 148 2 Ceiling cassette 4 way Compact type FDTC Models All moddels A PJA003Z341 ...

Page 111: ... 109 10 KX SM 148 b Duct type Models All models PJC001Z281 ...

Page 112: ... 110 10 KX SM 148 5 Ceiling cassette 1 way type FDTS Model FDTS45KXE6D B PJC001Z195 ...

Page 113: ... 111 10 KX SM 148 Model FDTS71KXE6D B PJC001Z196 ...

Page 116: ... 114 10 KX SM 148 Models FDUM112KXE6D 140KXE6D C PJR002Z259 ...

Page 120: ... 118 10 KX SM 148 Model FDK71KXE6D PHA001Z030 ...

Page 122: ... 120 10 KX SM 148 Models FDE71KXE6D 112KXE6D 140KXE6D C PFA003Z827 ...

Page 123: ... 121 10 KX SM 148 12 Floor standing 2 way type FDFW Models All models A PGF000Z004 ...

Page 127: ... 125 10 KX SM 148 5 APPLICATION DATA 5 1 Installation of indoor unit PJF012D016 a ...

Page 128: ... 126 10 KX SM 148 PJF012D016 A 1 Ceiling cassette 4way type FDT ...

Page 129: ... 127 10 KX SM 148 ...

Page 130: ... 128 10 KX SM 148 ...

Page 141: ... 139 10 KX SM 148 4 Ceiling cassette 1way compact type FDTQ PJC012D121 ...

Page 142: ... 140 10 KX SM 148 ...

Page 143: ... 141 10 KX SM 148 ...

Page 146: ... 144 10 KX SM 148 2 Parts Models QR PNA 14W ER QR PNB 14W ER PJC012D102 h ...

Page 148: ... 146 10 KX SM 148 ...

Page 149: ... 147 10 KX SM 148 5 Ceiling cassette 1way type FDTS PJC012D016 ...

Page 150: ... 148 10 KX SM 148 ...

Page 151: ... 149 10 KX SM 148 ...

Page 152: ... 150 10 KX SM 148 6 Duct connected High static pressure type FDU PJD012D053 ...

Page 153: ... 151 10 KX SM 148 ...

Page 154: ... 152 10 KX SM 148 ...

Page 158: ... 156 10 KX SM 148 8 Duct connected thin Low static pressure type FDUT PJM012D032 B ...

Page 159: ... 157 10 KX SM 148 ...

Page 160: ... 158 10 KX SM 148 ...

Page 161: ... 159 10 KX SM 148 9 Duct connected Compact and Flexible type FDUH PJC012D207 a ...

Page 163: ... 161 10 KX SM 148 ...

Page 164: ... 162 10 KX SM 148 PHA012D039 10 Wall mounted type FDK ...

Page 165: ... 163 10 KX SM 148 ...

Page 166: ... 164 10 KX SM 148 ...

Page 170: ... 168 10 KX SM 148 PGF012D004 12 Floor standing 2 way type FDFW ...

Page 171: ... 169 10 KX SM 148 ...

Page 173: ... 171 10 KX SM 148 13 Outdoor air processing unit type FDU F PJD012D059 ...

Page 174: ... 172 10 KX SM 148 ...

Page 175: ... 173 10 KX SM 148 ...

Page 184: ... 10 KX SM 148 182 ...

Page 212: ... 210 10 KX SM 148 2 model type DIS model type HEAD ...

Page 213: ... 211 10 KX SM 148 2 2 ...

Page 214: ... 212 10 KX SM 148 2 2 2 2 2 ...