INSPECTION AND REPAIR OF BASIC ENGINE

6-6

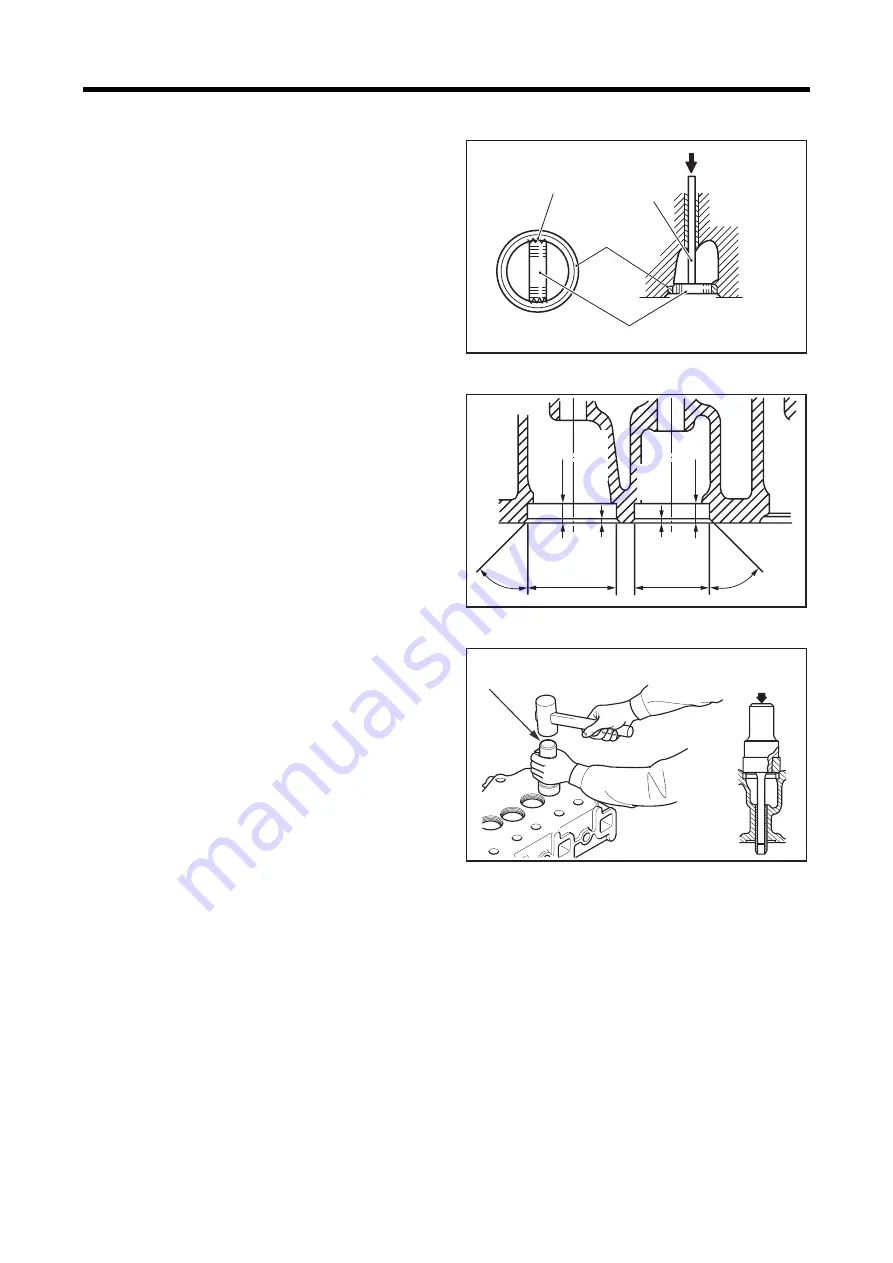

1.7 Replacing valve seat

(1)

To remove the valve seat, weld a stud to the valve seat

as illustrated. Then, insert a rod into the valve guide

hole from the top of the cylinder head, and press out the

valve seat with the rod.

Note: Be careful not to allow spatters to adhere to the

machined surface of the cylinder head during

welding.

(2)

Before inserting a new valve seat, measure the cylinder

head bore diameter and valve seat outside diameter to

make sure the interference meets the specified value.

(3)

Cool the valve seat at least for four minutes in liquid

nitrogen before fitting it into the cylinder head that is

kept at room temperature.

(4)

Fit the cold valve seat into the cylinder head using a

insert caulking tool.

Replacing valve seat

Valve seat fitting bore

Driving in valve seat

Valve seat

Weld

Stud

Shaft

8 ± 0.1

[0.31 ± 0.004]

8 ± 0.1

[0.31 ± 0.004]

2 ± 0.1

[0.08 ± 0.004]

2 ± 0.1

[0.08 ± 0.004]

45°

45°

ø46

+0.025

0

[1.81

+0.0010

0.00

]

ø37

+0.025

0

[1.46

+0.0010

0.00

]

Inlet

Exhaust

Unit: mm [in.]

Insert caulking tool

(Inlet)

P/N:36791-00200,

(Exhaust) P/N:

34491-03020

Summary of Contents for S4S

Page 2: ......

Page 4: ......

Page 16: ......

Page 36: ......

Page 48: ......

Page 49: ...3 1 SERVICE TOOLS 1 Special tool 3 2 ...

Page 56: ......

Page 102: ......

Page 122: ......

Page 146: ......

Page 154: ...LUBRICATION SYSTEM 9 8 2 3 Reassembling oil pump Reassembling oil pump Flush Flush ...

Page 159: ...LUBRICATION SYSTEM 9 13 3 2 Installing oil cooler Installing oil cooler Replace Replace ...

Page 208: ...ELECTRICAL SYSTEM 12 30 3 2 Installing alternator 12V 50A Installing alternator 12V 50A ...

Page 220: ......