-

-

'11•SAF-T-161

Ԟ

Drain pipe (continued)

ԟ

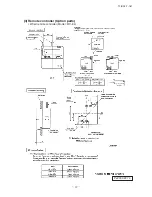

Wiring-out position and wiring connection

Ԡ

Check list after installation

٨

Electrical installation work must be performed according to the installation manual by an

electrical installation service provider qualified by a power provider of the country, and be

executed according to the technical standards and other regulations applicable to electrical

installation in the country.

Be sure to use an exclusive circuit.

٨

Use specified cord, fasten the wiring to the terminal securely, and hold the cord securely in

order not to apply unexpected stress on the terminal.

٨

Do not put both power source line and signal line on the same route. It may cause miscommu-

nication and malfunction.

٨

Be sure to do D type earth work.

٨

For the details of electrical wiring work, see attached instruction manual for electrical wiring

work.

1. Remove a lid of the control box (2 screws).

2. Hold each wiring inside the unit and fasten them to terminal block securely.

3. Fix the wiring with clamps.

4. Install the removed parts back to original place.

Insert water supply hose

for 50mm to

supply water.

(Insert hose facing

toward bottom.)

Attached drain hose clamp

Drain

piping

Main

unit

Drain situation can be checked with transparent socket.

If the electrical work has not been completed, connect a convex

joint in the drain pipe connection to provide a water inlet.

Then, check if water leaks from the piping system and that

drain flows through the drain pipe normally.

Pour water into a convex joint

Remove grommet

Make sure to Install

it back after test.

٨

Check the following items after all installation work completed.

٨

After completing the check, test-run the unit according to the procedure described in the

Outdoor Unit Installation Manual.

Check if

Expected trouble

Check

The indoor and outdoor units are fixed securely?

Falling, vibration, noise

Inspection for leakage is done?

Insufficient capacity

Insulation work is properly done?

Water leakage

Does the air flow falls within the range of

?

It cannot cool or warm

Water is drained properly?

Water leakage

Supply voltage is same as mentioned in the model name plate? PCB burnt out, not working at all

There is mis-wiring or mis-connection of piping?

PCB burnt out, not working at all

Earth wiring is connected properly?

Electric shock

Cable size comply with specified size?

PCB burnt out, not working at all

Any obstacle blocks airflow on air inlet and outlet?

Insufficient capacity

1

3

2

X

A

Y

B

5

4

3

2

1

6

Communication

terminal block

Remote control cable

Super Link cable

Total heat exchanger

terminal block

Indoor unit power cable.

Total heat exchanger cable

Band for driving

electric power cable

Band for light electric cable

Power supply terminal block

Do not connect the power

supply for the total heat

exchanger to the power

supply terminal block.

For further details, refer to the attached Electric Wiring Work Manual (see next page).

290~325mm

Drain hose

600

Maximum local drain up dimension

Joint for VP20 (local procurement)

Right overhead

Drain up

٨

The position for drain pipe outlet can be raised up to 600mm above the ceiling. Use elbows for

installation to avoid obstacles inside ceiling. If the horizontal drain pipe is too long before vertical pipe,

the backflow of water will increase when the unit is stopped, and it may cause overflow of water from the

drain pan on the indoor unit. In order to avoid overflow, keep the horizontal pipe length and offset of the

pipe within the limit shown in the figure below.

Otherwise, the construction point makes it same as drain pipe construction.

Drain test

1. Conduct a drain test after completion of the electrical work.

2. During the trail, make sure that drain flows properly through the piping and that no water

leaks from connections.

3. In case of a new building, conduct the test before it is furnished with the ceiling.

4. Be sure to conduct this test even when the unit is installed in the heating season.

Procedures

1. Supply about 1000 cc of water to the unit through the air outlet by using a feed water pump.

2. Check the drain while cooling operation.

PCH012D006