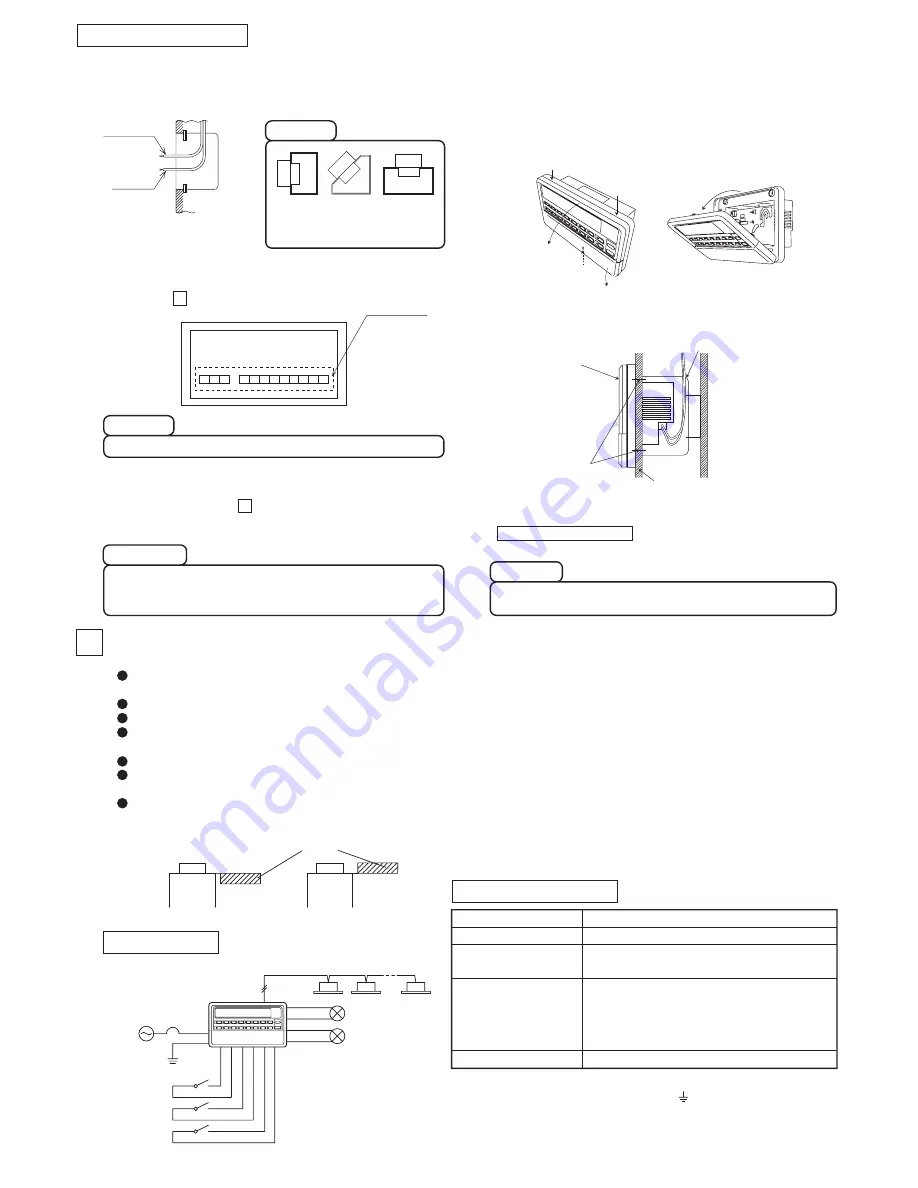

Terminal block

The back of the central control

Not allowed Not allowed

Allowed

Insulation covering

Allowed

Not allowed

Power supply wire

Signal wire

Note: Before connecting an external

timer or emergency stop input,

be sure to connect the wiring at

the worksite first.

④

③

④

③

②

①

Operation output

Error output

Emergency stop input

AC100V-240V

50/60Hz

Demand input

External timer input

Super Link signal wire

Grounding work

Local

switch

L1, L2

Central control

④

Pan-head screws

Electrical box

Internal wall or front side of the control board front

Note 1: When this central control is used, use a shielded wire for the Super Link signal wire.

Ground both ends of the shielded wire.

(Connect the ground for the central control to the section in "System Wiring".

Note 2: If the indoor and outdoor units connected to the network are all compatible units with

New Super Link, a total wire length of 1500m per line is possible (maximum distance:

1000m). However, be sure to use a 0.75mm

2

wire diameter if the total wire length

exceeds 1000m. For further information, please contact your sales representative or

dealer.

Refer to the figure below for the terminal orientation.

4

Electrical Wiring

Wiring Outline

Wiring Specifications

Power supply wire

Local switch

Super Link signal wire

(Note 1, Note 2)

Operation output, error

output, demand input,

emergency stop input,

external timer input wire

Grounding wire

1.25mm

2

10A

0.75mm

2

- 1.25mm

2

shielded wire (MVVS 2-core)

Max. 1000m per line (Max. distance: 1000m, Total wire length: 1000m)

0.75mm

2

- 1.25mm

2

CCV, CPEV (2-core)

Max. 200m

0.75mm

2

- 6mm

2

Installation Procedure

Caution

Caution

Check the supply voltage, and make the correct connection.

Caution

The case and power supply kit are an integrated unit. Please do

not separate them.

Please do not install facing

upward or at a slant.

(2) Open the top case by following the procedure below.

①

Grasp the indentations on the right and left sides, and

pull forward to open the cover downward.

②

Use a Phillips-head screwdriver to remove the screw. (Be

careful not to lose the screw.)

③

Open the top section in the direction

④

while gently

pressing the top section.

(1) In case of embedding in a wall, first, embed the power supply

wire, signal wire, and Electrical box.

Keep the power supply wire and signal wire separated to

prevent malfunctions.

(5) Use a precision screwdriver to make the control selector settings.

(For details, see section

Control Switch Selection

.)

(4) Use the supplied

④

pan-head screws to secure the central

control to the electrical box or control board.

(6) Peel off the protective sheet on the screen of central control.

Important

Please peel off the protective sheet on the air conditioner screen

when transferring the central control to the customer.

Peel off before mounting the top case.

(3) Connect the power supply wire to the terminal.

(See section

Electrical Wiring

.)

4

5

Before connecting the wires, remove the cover of the terminal block.

After the work is completed, fix the cover of the terminal block as before.

The cover is used to prevent electric shock due to accidental contact.

(7) Insert the top case back into its original location in the bottom

case as before, and tighten the case mounting screws

(

Installation procedure

(2)

②

).

This completes the installation procedure.

For safety reasons, please use the round crimping terminals with insulated sleeves for connecting all wires to the central control.

Please do the grounding work. Please do not connect earth line with gas pipes, water pipes, lightning rods and grounding line of

telephone.

Please do not turn on the power supply (local switch) until all of the work is completed.

Please wait at least two minutes after the indoor and outdoor units are turned on before turning on the power supply.

Except for the central control in the figure, all of the components are obtained at the site (wires, switches, relays, power supply,

lamps, etc.).

Please be sure to build the breaker which is easily accessible with building equipment's wiring.

Please be sure to use the supplied round crimping terminals when connecting wires to the power supply terminal block and

Super Link terminal block.

Please use demand input device, emergency stop input device and external timer input device comply with a relevant IEC Safety Standard.