-

7

-

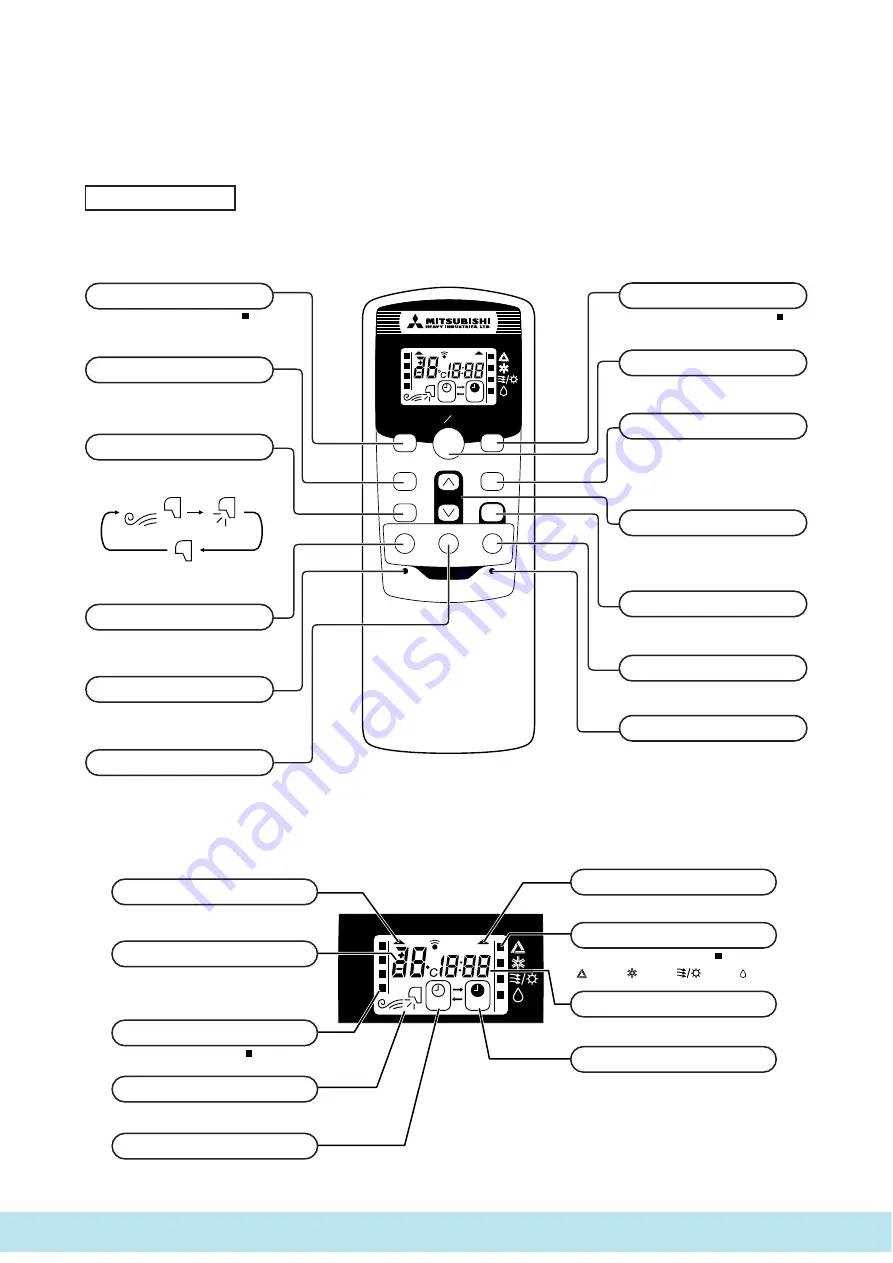

LO

MED

HI

AUTO

HI POWER

ECONO

ON

OFF

AM

PM

HI POWER TEMP

ECONO

AIR FLOW

CANCEL

ON

OFF

RESERVE

TIMER

TIME

ACL

FAN SPEED

ON

MODE

LO

MED

HI

AUTO

TIME

OFF

HI POWER

ECONO

ON

OFF

AM

PM

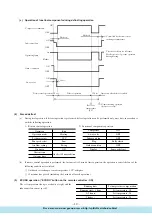

FAN SPEED button

Each time the button is pushed, the

indi-

cator is switched over in turn.

•

The above illustration shows all controls, but in practice

only the relevant parts are shown.

OPERATION MODE select button

Each time the button is pushed, the

indi-

cator is switched over in turn.

AIR FLOW button

This button changes the flap mode. When

pressed, this button changes the mode in the

following order:

ON/OFF button

Press for starting operation, press again for

stopping.

HI POWER button

This button changes the HI POWER mode.

ECONOMY button

This button changes the ECONOMY mode.

RESET switch

Switch for resetting microcomputer.

ON TIMER button

This button selects ON TIMER operation.

Clock switch

This switch for setting the clock.

OFF TIMER button

This button selects OFF TIMER operation.

TEMPERATURE button

This button sets the room temperature.

(This button changes the present time and

TIMER time.)

CANCEL button

This button cancels the ON timer and OFF

timer.

RESERVE button

This button sets the present time and

TIMER time.

S

Indication section

OPERATION MODE indicator

Indicates selected operation with

lamp.

[

(Auto) •

(Cool) •

(Heat) •

(Dry)]

TEMPERATURE indicator

Indicates set temperature.

(Does not indicate temperature when operation

mode is on AUTO)

FAN SPEED indicator

Indicates set air flow rate with

lamp.

AIR FLOW indicator

Shows selected flap mode.

HI POWER MODE indicator

Indicates during Hi power mode operation.

ECONOMY MODE indicator

Indicates during economy mode operation.

ON TIMER indicator

Indicates during ON TIMER operation.

Clock indicator

Indicates present time or timer setting time.

OFF TIMER indicator

Indicates during OFF TIMER operation.

Model SRK20HD

Remote controller

S

Operation section

4

OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

4.1 Operation control function by remote control switch

(Air scroll)

(Swing)

(Flap stopped)

Все каталоги и инструкции здесь:

http

:

//splitoff.ru/tehn-doc.html