-

24

-

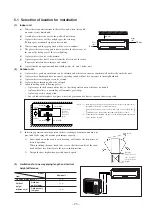

Adjustment of the installation board in the horizontal

direction is to be conducted with four screws in a

temporary tightened state.

5.2 Installation of indoor unit

(1)

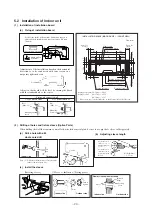

Installation of installation board

(a)

Fixing of installation board

(2)

Drilling of holes and fixture sleeve (Option Parts)

When drilling the wall that contains a metal lath, wire lath or metal plate, be sure to use pipe hole sleeve sold separately.

(a)

Drill a hole with ø65

whole core drill

(b)

Adjusting sleeve length

Adjust so that board will be level by turning the board

with the standard hole as the center.

Standard hole

(c)

Install the sleeve

(Inserting sleeve)

(* *In *Sealing plate)

Note (1) Drill a hole with incline of 5 degree from

indoor side to outdoor side.

Indoor side

Outdoor side

Cut off the sleeve

collar in case of

drawing piping out

to rear.

Cut off the sleeve

collar that can be

seen from beneath

the unit.

Wall thickness

+ 1.5 cm

Indoor side

Outdoor side

Turn to

tighten

Paste

View of sleeve when installed

Inclined

flange

Sealing

plate

Sleeve

Indoor side

Outdoor side

Mating mark for

level surface

Level position (2 locations)

450

Look for the inside wall structures (Intersediate support or

pillar and firaly install the unit after level surface has been

checked.)

INSTALLATION SPACE (INDOOR UNIT)

(FRONT VIEW)

Unit : mm

Piping hole( 65)

Piping hole( 65)

Installation board

Indoor unit

53.5

Piping for Gas 380.6

Piping for Liquid 448.6

Drain hose 520( 16)

53.5

Space *

for service

Space

for service

44.5

252.2

7.5

8.3

Space for

service

50

Space for

service

100

102.5

585

102.5

133.5

450

206.5

202

450

138

44.5

43.2

39.3

200

65

15

* Leave extra space on the right side to enable removal of the lid screw.

Fixing on concrete wall

Use of nut anchor

Use of bolt anchor

Bolt

(M6

×

12)

Mounting

board

Nut

(M6)

Mounting

board

Max. 10

Piping for Liguid (20~50type) : ø6.35

Piping for Gas

(20~35type) : ø9.52

(40, 50type) : ø12.7