-

3

-

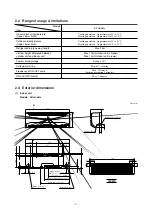

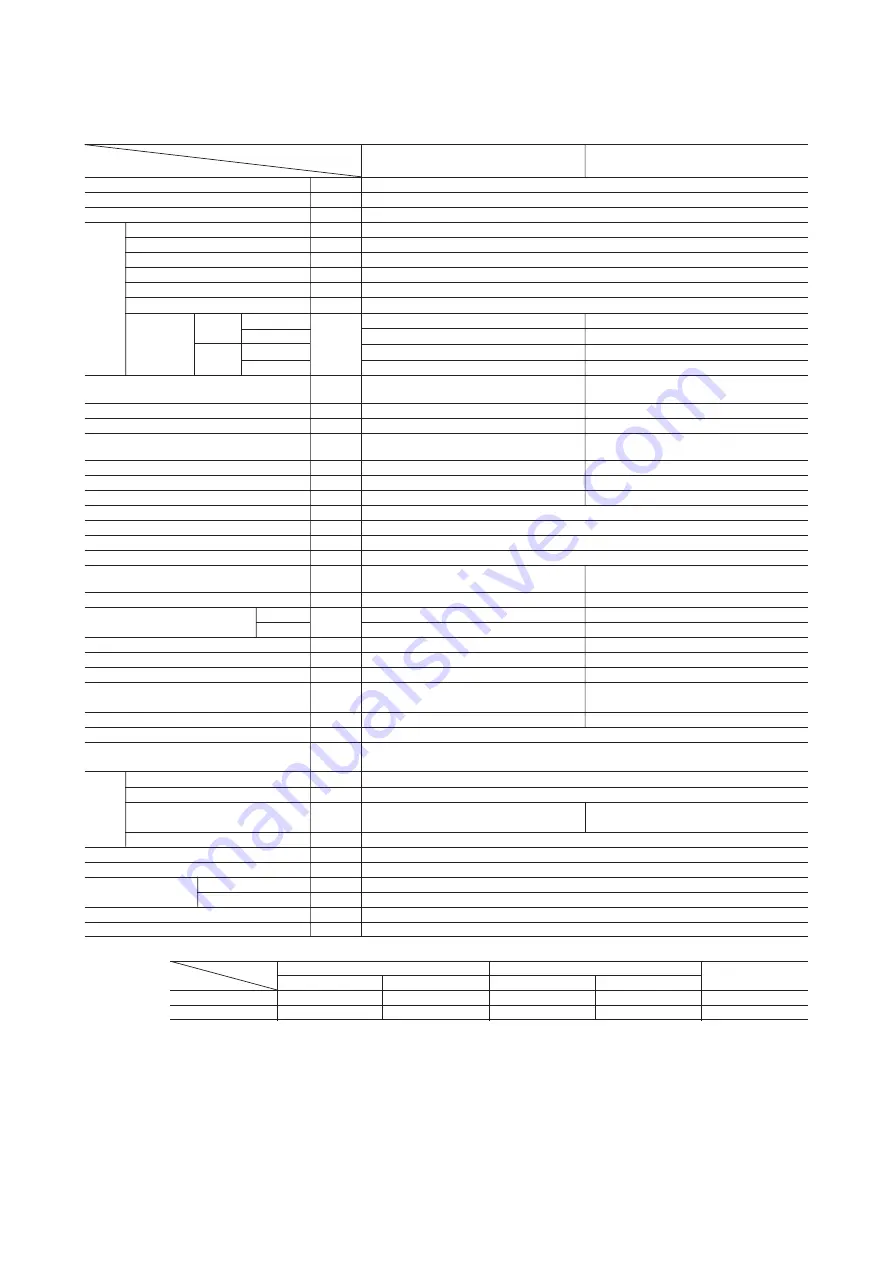

Model SRK28HG-S (Indoor unit)

SRC28HG-S (Outdoor unit)

Item

Model

SRK28HG-S

SRC28HG-S

Cooling capacity

(1)

W

2600

Heating capacity

(1)

W

2800

Power source

1 Phase, 220/230/240V, 50Hz

Cooling input

kW

0.81

Running current (Cooling)

A

3.8/3.7/3.6

Heating input

kW

0.77

Running current (Heating)

A

3.7/3.5/3.3

Inrush current

A

17.2

COP

Cooling: 3.21 Heating: 3.64

Cooling

Sound level

Hi: 39, Me: 33, Lo: 30

46

Noise level

Power level

dB

55

60

Heating

Sound level

Hi: 40, Me: 33, Lo: 29

46

Power level

56

60

Exterior dimensions

Height

×

Width

×

Depth

mm

268

×

790

×

199

540

×

780

×

290

Color

Fine snow

Stucco white

Net weight

kg

8.5

31

Refrigerant equipment

Compressor type & Q’ty

–

5PS102DAB (Rotary type)

×

1

Motor

kW

–

0.7

Starting method

–

Line starting

Heat exchanger

Louver fins & inner grooved tubing

Straight fin & inner grooved tubing

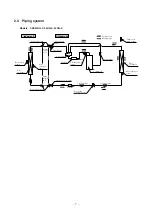

Refrigerant control

Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg

R410A

0.85 (Pre-Charged up to the piping length of 15m)

Refrigerant oil

R

0.35 (RB68A)

Deice control

Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan

×

1

Propeller fan

×

1

Motor

W

14

15

(Cooling)

8.5

29

Air flow (at High)

(Heating)

CMM

10.0

29

Air filter, Q’ty

Polypropylene net (washable)

×

2

–

Shock & vibration absorber

–

Cushion rubber (for compressor)

Electric heater

–

–

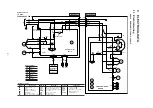

Operation control

Operation switch

Wireless-Remote control

–

Room temperature control

Microcomputer thermostat

–

Pilot lamp

RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D

mm (in)

Liquid line:

φ

6.35 (1/4

″

)

Gas line:

φ

9.52 (3/8

″

)

Connecting method

Flare connecting

Attached length of piping

Liquid line: 0.4 m

Gas line : 0.33 m

–

Insulation

Necessary (Both sides)

Drain hose

Connectable

Power source cord

2 m (3 cores with Earth)

Size

×

Core number

1.5 mm

2

×

4 cores (Including earth cable)

Connection wiring

Connecting method

Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter

×

1, Photocatalytic washable deodorizing filter

×

1)

Optional parts

–

Notes (1) The data are measured at the following conditions.

Item

Indoor air temperature

Outdoor air temperature

Standards

Operation

DB

WB

DB

WB

Cooling

27ºC

19ºC

35ºC

24ºC

ISO-T1, JIS C9612

Heating

20ºC

–

7ºC

6ºC

ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

Operation data

(1)

Refrigerant

piping

The piping length is 7.5 m.

(220/230/240V)

Frost protection, Serial signal error protection, Compressor overheat protection,

High pressure control, Indoor fan motor error protection