- 36 -

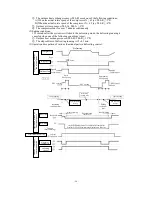

Flaring

Measurement B

Flaring

block

Copper

pipe

Model

Copper pipe

diameter

Measurement B

Clutch type flare tool

for R410A

Conventional (R22) flare tool

Clutch type

Wing nut type

Use a flare tool designed for R410A or a conventional flare tool. Please note that measurement B (protrusion from the

flaring block) will vary depending on the type of flare tool in use. If a conventional flare tool is used, please use a copper

pipe gauge or a similar instrument to check protrusion so that you can keep measurement B to a correct value.

Caution

Do not apply excess torque to the flared nuts. Otherwise, the flared nuts may crack depending on the conditions and

refrigerant leak may occur.

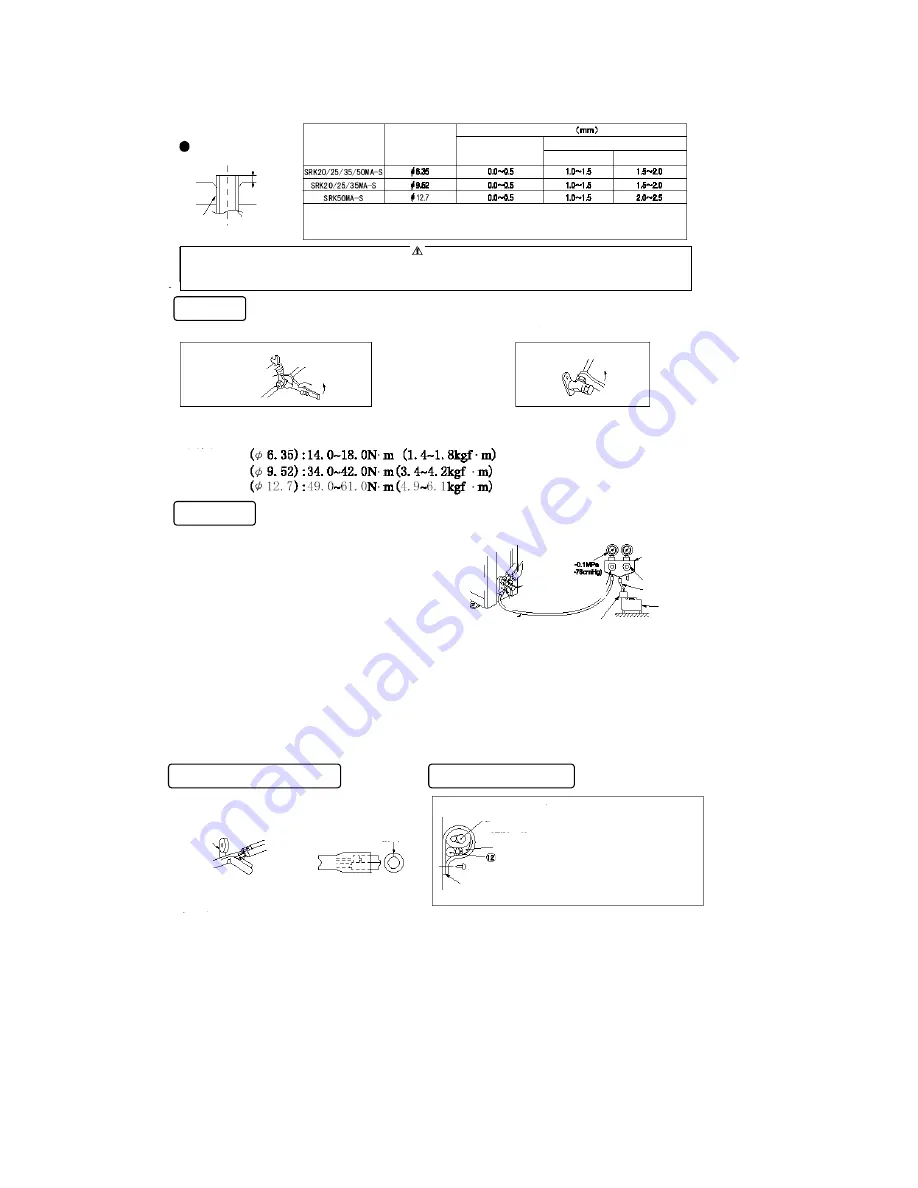

Connection

Indoor

Outdoor

Liquid side

Gas side

(Do not turn)

Liquid side

Gas side

○ Connect the pipes on both liquid and gas sides.

○ Tighten the nuts to the following torque.

Liquid side

Gas side

○ Connect the pipes on both liquid and gas sides.

○ All torques are the same as on the indoor liquid

side.

Air purging

①

Secure all flare nuts on both indoor and outdoor sides

to prevent leaks from the pipes.

②

Connect the operation valves, charge hose, manifold

valve and vacuum pump as shown in the right figure.

③

Fully open Handle

Lo

for the manifold valve, and

pump a vacuum for over 15 minutes. Ensure that the

meter is indicating -76cmHg (-0.1MPa).

④

After vacuuming, fully open the operation valve (both

liquid and gas sides) with a hexagon wrench.

⑤

Ensure that there are no gas leaks from the joints in

the indoor and outdoor units.

Compound

pressure gauge

Operation valve

(2-way valve)

Gauge manifold

(Designed specifically for R410A)

Pressure gauge

Operation valve

(3-way valve)

Service port

Charge hose

(Designed specifically for

R410A)

Vacuum pump adapter (Anti-reverse flow type)

(Designed specifically for R410A)

Handle

Hi

Charge hose (Designed specifically for R410A)

Handle

Lo

● Since the system uses service ports differing in diameter from those found on the conventional models, a

charge hose (for R22) presently in use is not applicable. Please use one designed specifically for R410A.

● Please use an anti-reverse flow type vacuum pump adapter so as to prevent vacuum pump oil from

running back into the system. Oil running back into an air-conditioning system may cause the refrigerant

cycle to break down.

Heat insulation for joints

Finish and fixing

Cover the joint with insulation material for the

indoor unit and tape it.

Vinyl tape

Position so the slit

comes on top.

Apply exterior tape and

shape along the place where

the pipes will be routed.

Secure to the wall with a

pipe clamp.

Pipe clamp

Pipes

Exterior tape

Drainage pipe

Tapping screw

Ground wire

Crossover wires

Earthing Work

○ Earth work shall be carried out without fail in order to prevent electric shock

and noise generation.

○ The connection of the earth cable to the following substances causes

dangerous failures, therefore it shall never be done. (City water pipe, Town

gas pipe, TV antenna, lightning conductor, telephone line, etc.)

Summary of Contents for SRC20MA-S

Page 10: ... 7 ...

Page 15: ... 12 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 20 25 35MA S ...

Page 16: ... 13 3 2 Circuit diagram 50MA S ...

Page 62: ... 59 12 Check method for outdoor unit 1 Circuit diagram of 20 25 and 35MA S outdoor units ...

Page 63: ... 60 2 Circuit diagram of 50MA S outdoor unit ...

Page 84: ... 81 ...

Page 87: ... 84 ...

Page 90: ... 87 ...

Page 93: ... 90 ...

Page 96: ... 93 ...

Page 99: ... 96 ...

Page 102: ... 99 ...

Page 105: ... 102 ...

Page 107: ... 104 18 RYF141A005 PLATE BAFFLE 1 19 RYF111A003F BASE ASSY 1 ...

Page 111: ... 108 19 RYF111A003F BASE ASSY 1 ...

Page 115: ... 112 19 RYF111A003F BASE ASSY 1 ...

Page 119: ... 116 19 RYF111A002G BASE ASSY 1 ...