- 67 -

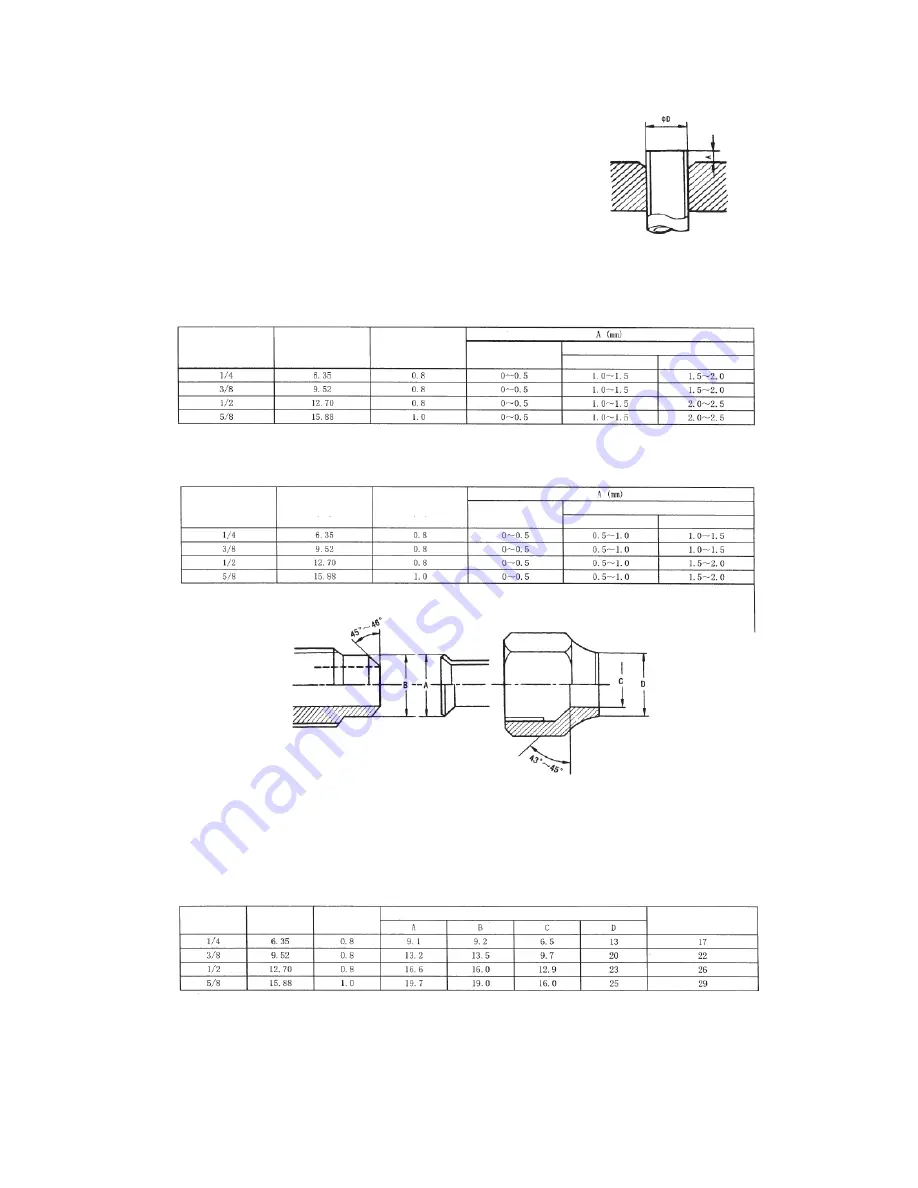

d) Flaring

Ensure to clean the clamps and copper pipes.

Use the clamping bars to conduct flaring correctly.

Use the flare tools for R410A or conventional flare tools.

The size of flaring varies depending on the kinds of flare tool. Please

note that the size must be adjusted to “Size A” with the size

adjustment scaled rule when using conventional flare tools.

Figure 3 Flare tool

Table 5 R410A flaring sizes

Table 6 R22 flaring sizes

Figure 4 Relationship between flare nut and flaring sealing surface

Table 7 Sizes of R410A flaring and flare nut

[Unit: mm]

Rating diameter Outside diameter

(mm)

Thickness

(mm)

Flare tool for R410A

Clutch type

Conventional flare tools

Clutch type

Wing nut type

Rating diameter Outside diameter

(mm)

Thickness

(mm)

Flare tool for R410A

Clutch type

Conventional flare tools

Clutch type

Wing nut type

Rating

diameter

Outside

diameter

Thickness

Size

Width of flare nut

Summary of Contents for SRC20MA-S

Page 10: ... 7 ...

Page 15: ... 12 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 20 25 35MA S ...

Page 16: ... 13 3 2 Circuit diagram 50MA S ...

Page 62: ... 59 12 Check method for outdoor unit 1 Circuit diagram of 20 25 and 35MA S outdoor units ...

Page 63: ... 60 2 Circuit diagram of 50MA S outdoor unit ...

Page 84: ... 81 ...

Page 87: ... 84 ...

Page 90: ... 87 ...

Page 93: ... 90 ...

Page 96: ... 93 ...

Page 99: ... 96 ...

Page 102: ... 99 ...

Page 105: ... 102 ...

Page 107: ... 104 18 RYF141A005 PLATE BAFFLE 1 19 RYF111A003F BASE ASSY 1 ...

Page 111: ... 108 19 RYF111A003F BASE ASSY 1 ...

Page 115: ... 112 19 RYF111A003F BASE ASSY 1 ...

Page 119: ... 116 19 RYF111A002G BASE ASSY 1 ...