- 68 -

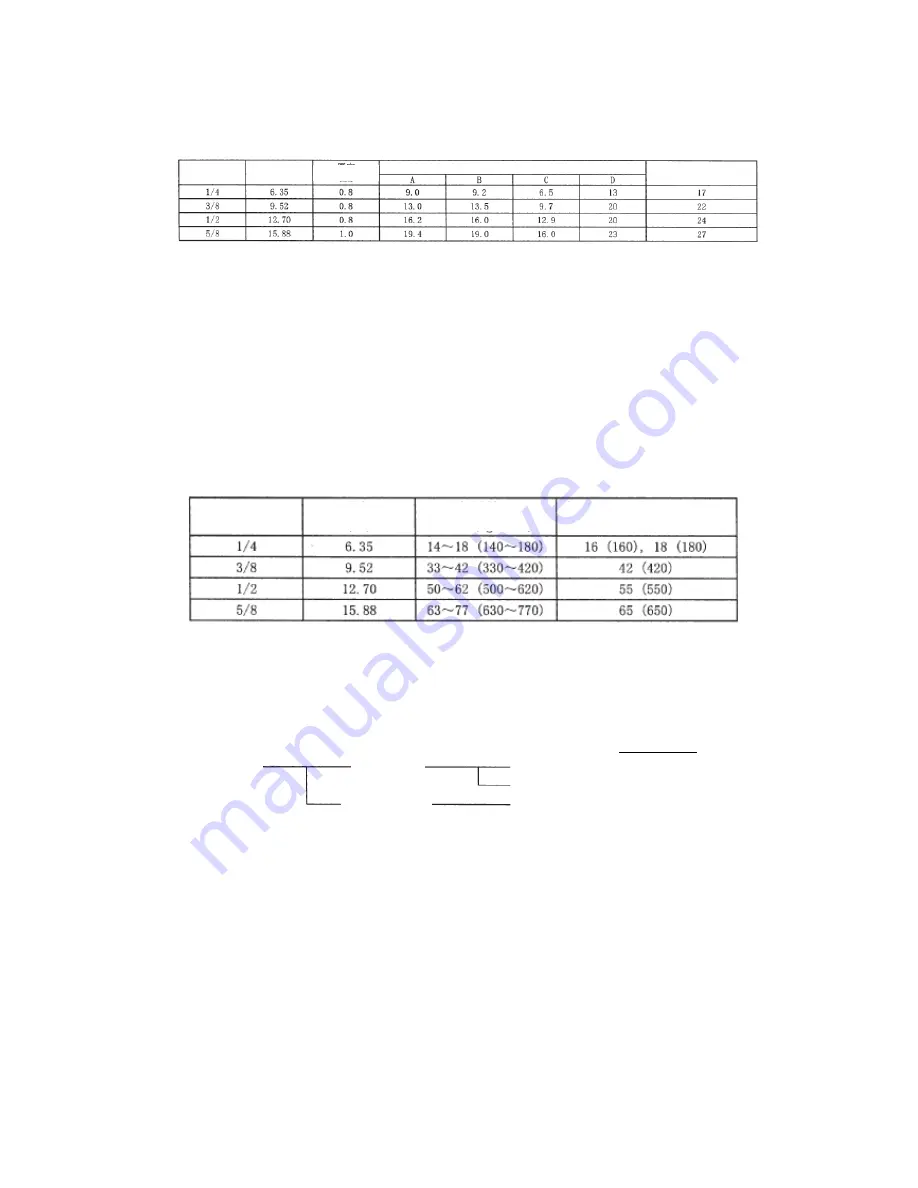

Table 8 Sizes of R22 flaring and flare nut

[Unit: mm]

(2) Flaring procedure and precautions

a) Ensure there is not any defect or dust, etc. on the flaring and connection.

b) Correctly connect the flared surface and the joint axis.

c) Use a torque wrench to tighten the flaring to the specified torque. The tightening torque for

R410A is the same as that for R22. Insufficient torque may cause gas leakage. Excessive torque

may cause the flare nut damaged and can’t be removed. Please select the tightening torque of

the value specified by the manufacturer. Table 9 shows the reference values.

Note: Apply the oil specified by the manufacturer on the flared surface. If other types of oil are used, it

may cause deterioration of the lubricant and failure of the compressor.

Table 9 Tightening torque for flaring for R410A [reference values]

7.2.3 Storage of piping materials

(1) Types and

storage of piping materials

The refrigerant piping materials for air conditioners are generally divided into the following types.

The pressure of R410A is higher than that of R22 by about 1.6 times, so be sure to use copper pipes

of the thickness as shown in Table 3 (see Page 56) and try to keep them clean. Be careful in

handling/storing copper pipes to avoid bending, distorting or damaging them. Be careful to prevent

dust, water, etc. from entering the pipes.

Seal the pipe opening with caps, etc. Ensure the sealing is intact during storage. To store coated or

bare copper pipes, use clamps, tape, etc. to fully seal the opening.

Rating

diameter

Outside diameter

(mm)

Thickness

Size

Width of flare nut

Rating

diameter

Tightening torque

N · m (kgf · cm)

Tightening torque of torque wrench available

on the market N · m (kgf · cm)

Refrigerant

piping

materials

With thermal

insulation

Without thermal

insulation

(Bare copper

pipe)

Flared

Not flared

Not flared

Common name

: (a) Pipe sleeve

: (b) Insulated copper pipe

: (c) Bare copper pipe

Outside

diameter

Summary of Contents for SRC20MA-S

Page 10: ... 7 ...

Page 15: ... 12 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 20 25 35MA S ...

Page 16: ... 13 3 2 Circuit diagram 50MA S ...

Page 62: ... 59 12 Check method for outdoor unit 1 Circuit diagram of 20 25 and 35MA S outdoor units ...

Page 63: ... 60 2 Circuit diagram of 50MA S outdoor unit ...

Page 84: ... 81 ...

Page 87: ... 84 ...

Page 90: ... 87 ...

Page 93: ... 90 ...

Page 96: ... 93 ...

Page 99: ... 96 ...

Page 102: ... 99 ...

Page 105: ... 102 ...

Page 107: ... 104 18 RYF141A005 PLATE BAFFLE 1 19 RYF111A003F BASE ASSY 1 ...

Page 111: ... 108 19 RYF111A003F BASE ASSY 1 ...

Page 115: ... 112 19 RYF111A003F BASE ASSY 1 ...

Page 119: ... 116 19 RYF111A002G BASE ASSY 1 ...