- 69 -

(2) Characteristics

a) Pipe sleeve

Copper pipes as R410A pipe sleeves must have a thickness as shown in Table 3 (see Page 59)

and Tables 5 and 6 (see Page 61), and sizes of flaring and flare nuts different from those of R22.

Therefore, be sure to select pipe sleeves suitable for R410A.

b) Insulated copper pipes

Before using insulated copper pipes, ensure their thickness is suitable for R410A.

c) Bare copper pipes

Be sure to use bare copper pipes of a thickness as shown in Table 3 (see Page 59) and try to keep

them clean. The surface of bare copper pipes is exposed, so be especially careful to handle them

and mark them to prevent misuse.

(3) Precautions before mounting

Pay attention to the following during pipe connection.

a) Before connecting to the appliance, use caps, etc. to seal all pipe opening.

b) Be especially careful in pipe mounting in rainy days.

If water enters the pipe, the lubricant may deteriorate, which causes failure of the appliance.

c) Connect the pipes as quickly as possible.

If the pipes are kept open for a long time, please fully charge them with nitrogen or use a

vacuum pump for drying.

7.2.4 Welding

(1) Processing

connection

Due to fusion cast between the surfaces of joints, which produces very high adhesive strength, be

sure to leave adequate space for welding and keep adequate gap between the surfaces of joints. The

minimum depth of penetration of joint of copper pipe, the outside diameter of inner pipe and the

gap between the outer pipe and the inner pipe are shown in Table 10. If copper brazing filler is used,

the pipe connection is the most secure when the gap is kept between about 0.05~0.1mm.

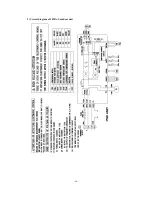

Table 10 Minimum depth of penetration and gap between copper pipe and joint

* When inserting the pipe, either process the end of the pipe or connect the pipe with a sleeve joint

through welding.

(2) Brazing filler

a) Alloy brazing filler

Alloy mainly composed of silver and copper is used to bond iron, copper or copper alloy. In

spite of its outstanding solderability, it’s expensive.

b) Phosphor bronze brazing filler

Phosphor bronze brazing filler is generally used to bond copper or copper alloy.

c) Low melting temperature solder

Alloy of tin and lead. Conventional solder. Due to its weak adhesive strength, it can’t be used for

refrigerant pipe welding.

* Notes:

1) BCuP reacts with sulfur easily and produces a complex aqueous solution, which may cause

gas leakage. Therefore, please use other types of brazing filler for SPA, etc. and apply paint

on pipe surface.

2) If welding is needed during servicing, please use the same type of brazing filler.

Inside diameter of

outer pipe

D (mm)

Minimum depth of

penetration

B (mm)

Gap

(A-D) x 1/2

(mm)

Summary of Contents for SRC20MA-S

Page 10: ... 7 ...

Page 15: ... 12 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 20 25 35MA S ...

Page 16: ... 13 3 2 Circuit diagram 50MA S ...

Page 62: ... 59 12 Check method for outdoor unit 1 Circuit diagram of 20 25 and 35MA S outdoor units ...

Page 63: ... 60 2 Circuit diagram of 50MA S outdoor unit ...

Page 84: ... 81 ...

Page 87: ... 84 ...

Page 90: ... 87 ...

Page 93: ... 90 ...

Page 96: ... 93 ...

Page 99: ... 96 ...

Page 102: ... 99 ...

Page 105: ... 102 ...

Page 107: ... 104 18 RYF141A005 PLATE BAFFLE 1 19 RYF111A003F BASE ASSY 1 ...

Page 111: ... 108 19 RYF111A003F BASE ASSY 1 ...

Page 115: ... 112 19 RYF111A003F BASE ASSY 1 ...

Page 119: ... 116 19 RYF111A002G BASE ASSY 1 ...