- 73 -

e) Flare tool (clutch type)

● The flare tool for R410A has a big clamping bar receiving hole, so as to set the copper pipe

portion protruding from the clamping bar during flaring to 0~0.5mm and have stronger elasticity

for the increased torque of EEV. This type of flare tool can also be used for R22 copper pipes.

f) Adjusting the scaled rule for the protruding portion (used when a conventional flare tool

(including clutch type) is used for flaring)

● A scaled rule with the thickness of 1.0mm helps setting the protruding portion of the copper

pipe in the clamp to 1.0~1.5mm.

g) Vacuum pump adapter

● In order to prevent the vacuum pump oil from returning into the charge hose, be sure to use an

adapter. The connection of the charge hose has two ports, one for conventional refrigerants

(7/16 UNF, 20 screw threads per inch) and one for R410A. If the vacuum pump oil (mineral oil)

is mixed with R410A, deposit may be produced, which will damage the appliance.

h) Refrigerant cylinder

● According to the U.S.A regulations, refrigerant cylinders

designed specifically for R410A are

marked with the refrigerant name and have pink coating.

i) Charging port and package for refrigerant cylinder

● According to the cap size of the charge hose, a charging port (1/2 UNF, 20 screw threads per

inch) and corresponding package are required.

j) Gas leakage detector

● Use a highly sensitive gas leakage detector

designed specifically for HFC refrigerants. For

R410A, the detection sensitivity is about 23g/ year.

(2) Frequently used tools

a) Vacuum pump

b) Torque wrench

For 1/4, side-to-center distance 17 mm x

(16 N · m)

(160 kgf · cm)

For 1/4, side-to-center distance 17 mm x

(18 N · m)

(180 kgf · cm)

For 3/8, side-to-center distance 22 mm x

(42 N · m)

(420 kgf · cm)

c) Pipe cutter

d) Driller

e) Screw driver (+,-)

f) Steel saw

g) Hollow drill (Φ65 or 70)

h) Hexagon wrench

(side-to-center distance 4 or 5

mm)

i) Wrench or monkey wrench

j) Tapeline

k) Thermometer

l) Clamping ammeter

m) Insulation resistance meter

(megameter)

n) Circuit tester

o) Pipe bender

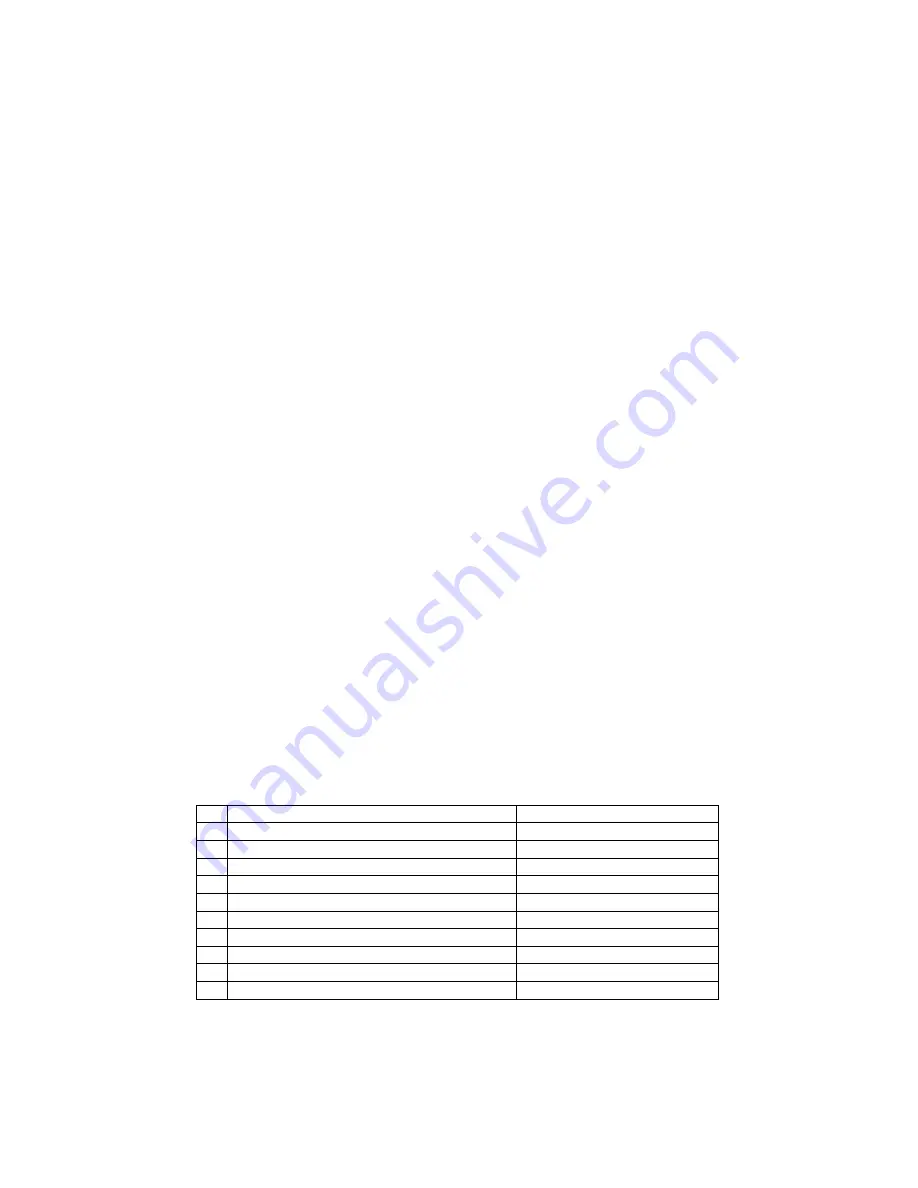

(3) Applicability of tools for R410A to models using R22

Table 15 Applicability of tools for R410A to models using R22

Tools for R410A

Applicability to models using R22

a)

Manifold pressure gauge

X

b)

Charge hose

X

c)

Electronic loadcell scale for charging refrigerant

O

d)

Torque wrench (rating diameter 1/2, 5/8)

X

e)

Flare tool (clutch type)

O

f)

Scaled rule for adjusting protruding portion*

O

g)

Vacuum pump adapter

O

h)

Refrigerant cylinder

X

i)

Charging port and package for refrigerant cylinder

X

j)

Gas leakage detector

X

* Used when the conventional flare tool (clutch type) is used.

Note: If you have any questions, please consult your dealer.

Summary of Contents for SRC20MA-S

Page 10: ... 7 ...

Page 15: ... 12 3 ELECTRICAL WIRING DIAGRAM 3 1 Circuit diagram 20 25 35MA S ...

Page 16: ... 13 3 2 Circuit diagram 50MA S ...

Page 62: ... 59 12 Check method for outdoor unit 1 Circuit diagram of 20 25 and 35MA S outdoor units ...

Page 63: ... 60 2 Circuit diagram of 50MA S outdoor unit ...

Page 84: ... 81 ...

Page 87: ... 84 ...

Page 90: ... 87 ...

Page 93: ... 90 ...

Page 96: ... 93 ...

Page 99: ... 96 ...

Page 102: ... 99 ...

Page 105: ... 102 ...

Page 107: ... 104 18 RYF141A005 PLATE BAFFLE 1 19 RYF111A003F BASE ASSY 1 ...

Page 111: ... 108 19 RYF111A003F BASE ASSY 1 ...

Page 115: ... 112 19 RYF111A003F BASE ASSY 1 ...

Page 119: ... 116 19 RYF111A002G BASE ASSY 1 ...