-

61

-

d) Flare processing

Make certain that a clamp bar and copper pipe have been cleaned.

By means of the clamp bar, perform the flare processing correctly.

Use either a flare tool for R410A or conventional flare tool.

Flare processing dimensions differ according to the type of flare tool. Be careful. When

using a conventional flare tool, be sure to secure “dimension A” by using a gage for size

adjustment.

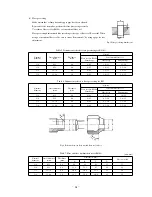

øD

A

Fig.3 Flare processing dimensions

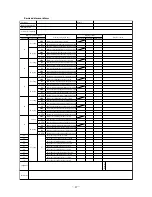

Table 5. Dimensions related to flare processing for R410A

Nominal

Outer diameter

Thickness

A (mm)

diameter

(mm)

(mm)

Flare tool for R410A

Conventional flare tool

Clutch type

Clutch type

Wing nut type

1/4

6.35

0.8

0~0.5

1.0~1.5

1.5~2.0

3/8

9.52

0.8

0~0.5

1.0~1.5

1.5~2.0

1/2

12.70

0.8

0~0.5

1.0~1.5

2.0~2.5

5/8

15.88

1.0

0~0.5

1.0~1.5

2.0~2.5

Table 6. Dimensions related to flare processing for R22

Nominal

Outer diameter

Thickness

A (mm)

diameter

(mm)

(mm)

Flare tool for R410A

Conventional flare tool

Clutch type

Clutch type

Wing nut type

1/4

6.35

0.8

0~0.5

0.5~1.0

1.0~1.5

3/8

9.52

0.8

0~0.5

0.5~1.0

1.0~1.5

1/2

12.70

0.8

0~0.5

0.5~1.0

1.5~2.0

5/8

15.88

1.0

0~0.5

0.5~1.0

1.5~2.0

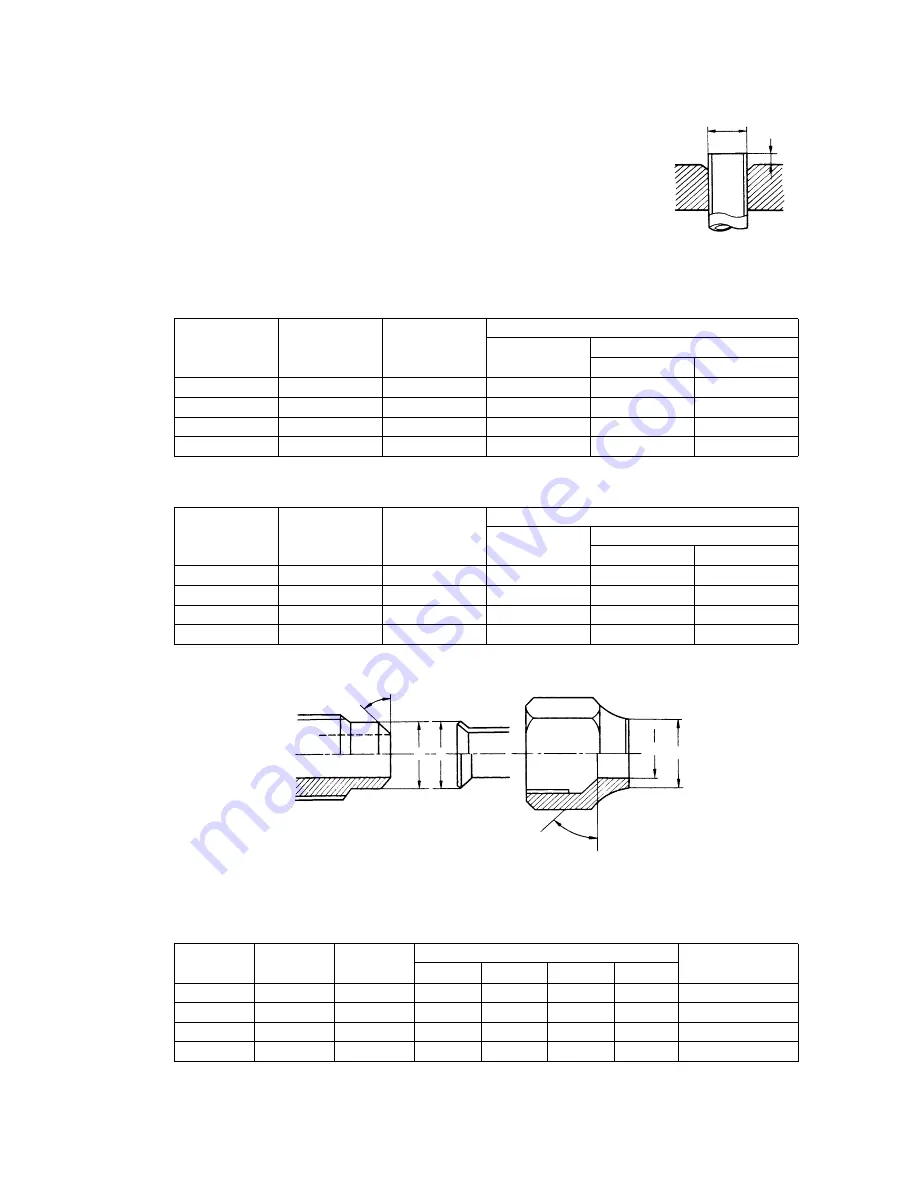

Fig.4 Relations between flare nut and flare seal surface

45

°

~46

°

B

A

43

°

~45

°

C

D

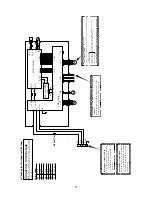

Table 7. Flare and flare nut dimensions for R410A

Nominal

Outer diameter

Thickness

Dimension (mm)

Flare nut width

diameter

(mm)

(mm)

A

B

C

D

1/4

6.35

0.8

9.1

9.2

6.5

13

17

3/8

9.52

0.8

13.2

13.5

9.7

20

22

1/2

12.70

0.8

16.6

16.0

12.9

23

26

5/8

15.88

1.0

19.7

19.0

16.0

25

29

[unit: mm]